Image Credit: All images: Marc Rosenbaum

Image Credit: All images: Marc Rosenbaum This graph shows the power input to the Fujitsu minisplit at our house on January 26, 2015, as outdoor temperatures rose and the blizzard began. The power draw dips below 250 watts indicate defrost cycles.

Defrost cycles prevent freeze-ups

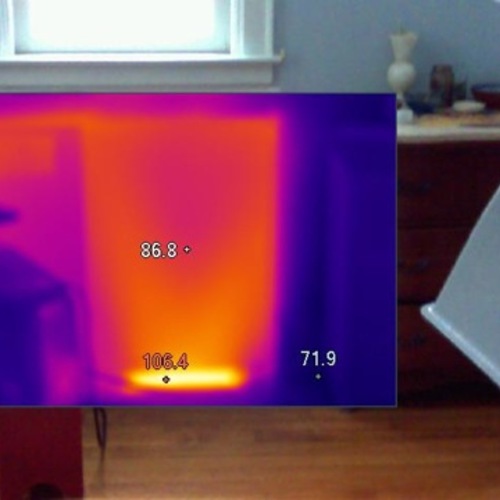

Heat pumps are designed to sense this type of condition, and periodically operate a defrost cycle, in which the heat pump reverses and uses some energy to melt the frost off the coils. Below is a photo of a Fujitsu condenser with frost building up:

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

Here’s the same condenser after the defrost cycle:

Here’s a Daikin condenser that I think has a faulty defrost cycle. (The photo below was taken at a house at which South Mountain has installed a solar electric system.) The frost has built up considerably:

So, the above photo excepted, we’ve been talking about normal conditions, not a blizzard. Image #2 (at the bottom of this article) is a graph showing the power input to the Fujitsu at our house on January 26, 2015, as outdoor temperatures rose and the blizzard began.

Through about 2:00 p.m., the outdoor temperatures were in the mid-to-upper 20Fs, and the defrost cycles, marked by the dips in power draw, occurred roughly every 4 hours, lasted 4-5 minutes, and drew under 250 watts. Once the storm starts up, outdoor temperatures are right around freezing, and the fine snow is being whipsawed around by the strong winds, which can drive the snow into the coil, coating it and triggering the defrost cycle.

The blizzard becomes a moisture delivery system. The defrost cycles are much more frequent, slightly over once per hour. And the duration rises to 15 minutes or so, with a power draw of 500 watts. Note also that after the defrost cycle the heat pump power draw jumps up to 900 watts or so, whereas before the storm it was running at 450 watts for much of the time.

It appears that the firmware drives the heat pump up to the higher power draw for a certain amount of time after every defrost cycle, and when the cycles are frequent, it never drops down to the “cruising” power draw. So both efficiency and capacity are reduced, because the energy going into defrost isn’t going into the house. You can tell when the defrost cycle occurs because the indoor fan shuts off — otherwise it would be blowing cold air.

The condenser needs clearance beneath it, because the melt from the defrost cycle is going to freeze once it drips down off the condenser, and in the worst case it freezes under the condenser and crushes the lowest row of the coil and the unit is ruined. So it makes sense to raise the condenser above the snow line and keep it under an overhang or roof.

This all becomes more severe if the condenser is actually buried in snow. In the worst case, the heat pump shuts down, and we saw this at a couple of houses here. My own unit is up off the ground, and under a small roof, but the January 26-27 storm came from the northeast and still packed the gap between the house and condenser 40-50% full of snow. We’re considering doing more wall-mounted installations, getting them at least 2 feet off the ground — but architects don’t want to see the condenser(s), so the inclination is to install them low to the ground and behind screening. But this usually makes them more vulnerable.

Here’s a neat wall-mounted installation:

We’ve been pleased that these seem not to impart vibration to the house, the units must be very well-balanced.

Does this mean that houses heated by minisplit heat pumps, with no back-up heating system, are more vulnerable in bad storms than houses heated by modern fossil fuel burning equipment? Not necessarily — those fuel-burning units have their own issues in storms. Sealed-combustion sidewall vents can be plugged by ice or wind-driven snow, and wind gusts can cause the pressure-sensing switch to shut the units down.

So modern heating systems in general are more twitchy in severe weather than the old atmospherically vented boiler venting into a interior masonry chimney, with a barometric damper. Do we want to go back to that? For a number of reasons, I’d say no. Houses that need that big boiler or furnace are much more likely to freeze up when that unit goes down (say, in a power outage) than a small superinsulated house with a minisplit.

My sense is, get ’em up off the ground, and check them in a bad storm.

Marc Rosenbaum is director of engineering at South Mountain Company on the island of Martha’s Vineyard in Massachusetts. He writes a blog called Thriving on Low Carbon. Marc teaches a 10-week online Zero Net Energy Home Design course as part of NESEA’s Building Energy Master Series. You can test drive his class for free.

42 Comments

mini-splits and blizzards

Marc - In your opinion, if one did have back up heat, say a small wood stove or a small direct vent gas or kerosene burner, would it make sense to turn off the mini split during the blizzard and use the back up?The last two blizzards here in coastal Maine came with frigid temperatures.Does turning the units off and on, while maintaining good in house temperatures decrease the efficiency of the units? Thanks.

Kevin, I'd say it's a choice,

Kevin, I'd say it's a choice, which ever of the units would be most reliable. The fossil fuel units are susceptible to the same aspects of the blizzard. If you're present, you can keep ahead of the snow perhaps. I wouldn't turn the heat pump off unless you are using another heater, in which case I would turn it off, and clean up the snow post-storm.

Quite a winter we're having

Marc,

Thanks for sharing your observations and data. Down on Martha's Vineyard, you've been getting some snow, but I doubt if you've been seeing the temperatures we've been seeing lately in northern Vermont, northern New Hampshire, and the Adirondacks.

We've seen below-zero temperatures almost every night or several weeks. A.J. Builder recently posted a comment about -32°F; here in Vermont, it's been warmer. (The coldest temperature I've seen this winter is -29°F.)

Here's my question to GBA readers who live in northern Vermont and northern New Hampshire: since we are all waking up every morning to discover that our thermometers are reading -25°F, or -19°F, or -15°F, day after day for weeks, how is your ductless minisplit performing this winter?

Extreme cold

I checked in recently with Ben Southworth of Garland Mill Timberframes in Lancaster, NH, north of the White Mtns. It seems that the Fujitsus he has installed on projects we worked on together up there have been continuing to run. These are all superinsulated houses.

That said, I'd be hesitant designing with a minisplit as the sole heat in that climate. Two 1500W kickspace heaters are awfully cheap insurance!

Looking forward to hearing from others in the frozen north!

Iced up

My Daikin does the same thing, getting just about completely

packed up with hoarfrost on the intake side for a while before

finally deciding to defrost. Swirling snow makes it happen much

faster, of course. I think what happens is that when the fan

can't pull air *through* the coil it starts acting more like a

centrifugal blower, still managing to swirl enough ambient air

around in front of the coil that it can still transfer enough

heat. In watching the saturated evaporation temps a bit I've

seen that at some point the average coil temp starts dropping

fairly rapidly, and that's when heat transfer is finally cut

off and the unit forces a defrost cycle even if it's outside

of the usual time-based schedule. I've got the field-setting

to "long" but I'm not exactly sure what that really means;

I was hoping it means fewer defrosts when it isn't necessary.

Previous years I also had trouble with the dumb wire lattice

grille thing Daikins usually come with, mounted less than half

an inch from the back of the coil and causing more ice buildup

that the defrost cycle heating couldn't actually reach. I see

that your unit doesn't seem to have one at all, which probably

helps. I finally yanked that thing off and built a better screen

that sits an inch-plus away and can't bridge ice over to the coil.

What's been happening with mine, though, is that even though the

unit is adequately elevated the drain hole in the bottom plugs

up and an ice layer builds up in the bottom of the box. I'm

hoping that freeze/thaw cycle expansion doesn't produce any

damage there. This could happen to any type of unit, I suppose,

unless it's left *very* open at the bottom which you don't actually

want to prevent various critters from moving in. After the last

round of blizzards [plural!] I decided to do a longer manual defrost

and get rid of some of that, the methodology for which is shown

near the end of this page along with how I've been maintaining

shoveled-out space around the condenser box. Not hard to do,

really, and I'm sure I could have been far less anal about it.

I think our lowest low was -5 or thereabouts, and the system

was holding its own fine all the way through that. When I had

it deliberately set on "reduced demand" capacity in the process

of playing around with COP tuning, I finally started seeing its

limits -- ran all night and never quite reached setpoint, which

tells me that my design load *is* right around one ton worst-case.

[Early calculations seem to indicate a healthy increase in running

COP, too, which I was asking about a little while back -- from

like 3.0 to about 3.6; I'll have better data later.]

But this winter's been one that has me thinking maybe we need

to start re-thinking design temps in these parts...

_H*

Manual defrost

Hobbit, those are great photos!

What actually happens with the tarped off condenser when you're in cooling and the fan flow is restricted like that?

Adirondacks this

Adirondacks this winter

Southern, my area constant -15ish nights 5-20ish days the whole Winter. Very unusual. No break from it is the real unusual aspect.

Northern Adirondacks is 10 degrees colder.

Adirondackers either have wood or pellet stoves for added heat or even primary heat. Regular working types.... Not the case of course for the very wealthy.

I would always install a second heat source to back up a heat pump. Also the heat pump would be oversized and set to work the hardest from noon to six PM. Am heat from Electric Matt Bath Floors and kitchens then off to work. Add Electric Matt Tile under at home work stations if that is the case.

tarped

The tarped-up run was interesting, actually. It was so cold out

that the fan hardly ran at all -- in cooling mode with a subfreezing

ambient, it wouldn't have to! As the whole box warmed up, the

outdoor temp sensor on the back probably became more deceived and

the fan started to run a little but still very slowly. I had

everything tied down so all it did was rattle the tarp in front

of the fan a little and probably helped move the warmed air down

around the baseplate where it was most needed.

This was done in "test mode", of course, where otherwise calling

for cooling might elicit some sort of "you've gotta be joking"

response from the controller.

_H*

Good Artical

Hopefully they fix these issues with mini splits in the future. Just glad I got the 26" PTHP's in the rentals so I don't have to worry about this in Zone 6 during this cold snap. Personally a EPA wood burning stove looks great during these times.

Cooling mode & defrost

Just a little side note brought up by Hobbit's post - many of these heat pumps ARE rated for low ambient temperature cooling mode. My Mitsubishi unit's specs say it will operate in cooling mode down to 14F. Not sure about your Daikin, Hobbit, but you might be able to do your forced defrost without pushing the "test" button.

To Marc's comment in the article about high power input on startup following a defrost - I see the same. I suspect it has to do with these units' "hot start" control logic that seems to err on the side of better occupant comfort, rather than better efficiency....at least at start up.

Snow depths WILL vary.

I've been advising folks in central MA to wall-mount them under the roof overhangs at least 4' above grade to avoid those issues, remembering the record snow year of '96-97.

But the average snowpack depth in my Worcester front yard right now is currently about 3.5-4' ( the settling of 103" of snowfall in the past 4-5 weeks), and where I've had to shovel snow off the roof to lower the load it's averaging 6' or more.

Methinks after this winter I'll have to bump up my recommended mounting height, since 4' is clearly not high enough in drifting wind. I had 6' drifts in my driveway after the first big nor'easter, which dumped about 34" (average) all in one go.

This winter has me nervous

This winter has me nervous about using mini-splits as my primary heat source, after convincing myself that it would be the way to go.

I'm in CNY/southern Adirondacks, and we have had lots of -20 weather this year, today is the first day in over a week that the temp has gotten out of the single digits.

Guess I'll have to put more thought into a back up plan, pellets, or wood stove.

Don't worry Trevor

I was similarly concerned, but once my house was insulated, it became apparent that it won't take much to'stay warm. Still under construction, the house is easily heated by a temporary 17kbtu electric heater that has no trouble keeping up with -15F nights. When I show up at 7:30 AM to pester the contractors, they are usually working in t-shirts and more often than not, the heat is not running. I think once we swap the sheet of osb for the front door, it will be even cozier. Almost invariably, when it's mega-cold at night, it's sunny the next day, so solar gain will help.

I'm planning on two minisplits, 9k and 12k, with minimal electric resistant backup and a very small, 13kbtuh gas fireplace. House is 1650 square feet of conditioned space, with very high ceilings. 16kbtuh design heat load at 0°.

The other reason not to worry is that a really tight, well insulated house can coast through those bitter nights without any meaningful heat input, other than the occasional golden retriever.

As a bachelor with a kid who likes the cold

I've been able to test using a minisplit as the primary heat source, and there are some pitfalls.

For those who experience real winters with constant low temps, ice build up in the pan is an issue that has no easy solution that is energy efficient.

Once the drain holes freeze over, the unit slowly fills up until you get a good spell of 40 degree weather. I don't understand the comment about it hurting the compressor the compressor as much but it will eventually prevent the fan blades from spinning, which I've run into.

Fujitsu has an HSPF rating on their models with and without a pan heater and it takes quite a hit of over a couple points. Your basically heating the outdoors with 120watts of resistance all winter.

Other gotchas:

-When it's the only heat source, you really notice when it goes into defrost mode. And when it is really cold outside, like say -10, that subtle cold air blowing gently can really make you unhappy. Also not having control of when it triggers makes it feel like it only triggers at the worst of times.

-Noise, noise, noise. Again in defrost mode during long defrosts, the indoor unit cools a lot, which causes contraction and all the crackling noises. And then it reverts to heat, high heat and the thing crackles and pops expanding. That along with the 'whooshing' of refrigerant as it changes cycles and ramps up. The indoor unit seems very cheap compared to the outdoor unit.

-You lose (for many) the convenient automatic humidifying source - and its regulation - that was once connected to the HVAC system. You can install it in supplemental air.

And you lose what I found to be a convenient point for a whole house filter in the HVAC system, a real filter and not some mesh screen.

-If you do use an alternate heating source, and switch off the minisplit, you still have to pay for the outside unit to 'stay warm' and ready to go and prevent refrigerant moisture ice up unless you go hit the breaker on it.

I will say it is remarkable to have it below -20 degrees outside and still have this thing output heat. The service manual says it will shut down in that range, but so far it hasn't during the past two winters.

It's hard to take a good pic of the inside; in the rear pick below of my Fuj you get an idea of how high the ice has built up in it at the point of the picture. The condensate starts to pour out the back and freeze. [I removed the plastic grid as ice/snow would collect on it and it didn't appear to serve any real purpose, except the part over the thermistor]

My fix is a hot five gallon bucket of water which cracks the inside ice into pieces and I pull the large chunks out, then flush the drain holes.

For a stand, I mounted it on two retaining wall pavers as the bracket and other systems are fairly ugly and it matches the other pavers.

Response to Bob Coleman

Bob,

Thanks for your perceptive and useful comments.

drain pan heaters

Great topic, thanks. We've installed 10 mitsubishi hyperheats of various sizes and mounting strategies. Marc's experience jibes with mine. I've been worried about vibration on wall mounts so I've only used the brackets on masonry. I do wish somebody would make a less hideous steel stand. The only problems I've seen are on units that don't have at least 8" ground clearance. As Marc points out in these extended periods of sub freezing the ice builds up underneath to the point where it clogs the drain hole, and there goes the condenser.

Mitsubishi sells a drain pan heater as an option. It comes on during defrost at temps below 36 degrees and consumes 80-100 Watts. I haven't used them, but I know some contractors use them everywhere. Tough call--maybe some client maintenance and a bit of risk on one side against the cost of using power as insurance on the other.

BTW, and off topic, somebody on heating help posted an interesting analysis of the effect of installation faults on heat pump performance. Apparently faults are quite common.

http://nvlpubs.nist.gov/nistpubs/TechnicalNotes/NIST.TN.1848.pdf

Eep!!

Well, I just made the rather disturbing discovery that the ice that

has built up [again] in the bottom pan of the outdoor unit has been

*pushing* tne entire coil area upward as it re-freezes, fortunately

without any apparent damage so far but a noticeable upward bowing

of of the top of the cabinet. Fortunately, refrigeration tubing

is a bit flexible ... but this morning's activities include more

tarped-up test runs, thus air-conditioning the house nicely in 15

degree weather, and *removing* the unit's fan entirely this time

so it can't try to eject any of the warmed air inside.

The fan was actually scraping lightly on the top of its shroud, which

alerted me to the cabinet distortion in the first place.

Might have to run some heat tape around the bottom of this thing and

take some amount of efficiency hit to keep the drainage path clear.

UPDATE a little later: well, it looks like the ice actually pushed

the fan bracket itself up a little rather than the coil, which is a

relief. It's mounted in sort of a funky way, probably to reduce

vibration, such that ice can sit underneath part of the mounting

flange and put upward pressure on a pair of L-brackets that the

fan frame bolts on to. Still, having all the ice around the coil

can't be good for it in general either.

_H*

Fuji performing well through two Maine blizzards

Our Fujitsu minisplit is doing a good job of heating our new 2,300ft2 net zero-ready home all by itself here in Brunswick. I did have to remove ice caked onto the back of the outside unit recently after the snow that accumulated behind it turned to ice.

Manufacturers comments

It would be very interesting if some of the manufacturers would add some comments to this article.

Mitsu and this winter

Our heat pump is mounted on a stand, about 2 feet off the ground. We have had to dig it out twice this winter. It does have a pan heater, so ice build up in the bottom is not a problem. The ice build up on the coils is a big problem. After the last storm, the unit was still putting out heat, but was completely buried. It now sits in a pit, surrounded by about 6 feet of snow. We live just outside Saint John, in New Brunswick, Canada. Our high temperatures have been hovering around 0 F. Snow pile by the driveway has reached about 12 feet. We kept our baseboard heaters when we installed the HP, so we are not too worried. In our climate it would be foolish to rely on the HP alone.

enclosed heat pump?

We also are near Saint John , NB and this is the first winter for the heat pump. It is mounted 2 feet up on the back wall in a corner that collects an incredible amount of snow from our non stop blizzards this winter. It has been completely buried and dug out a few times. And then there's the snow off the roof adding to it. I am thinking, if we ever see the ground again, of building a little house around it with a shed roof. I realise the unit needs air flow so what about a couple of 8' diameter ducts coming out of it's roof with a snorkel bend in the top to keep out snow. They could be fastened to the house wall for stability. Any reason this wouldn't work ?

Response to Kathi Dunphy

Kathi,

Did you really mean 8-foot-diameter ducts? Those are huge. You probably meant 8-inch-diameter ducts.

I'll leave it someone else to do the math, but I'm fairly sure that "a couple of 8-inch-diameter ducts" will not provide enough air flow for efficient operation of the heat pump. But you can always contact the manufacturer's technical help hotline to see if your plan violates the manufacturer's installation instructions. I bet it does.

I live in a climate that regularly sees 5-foot-deep snow. Lots of people are seeing deep snow this winter. If you have an air-source heat pump, it should be mounted above your expected snow depth. Obviously, 2 feet above grade isn't working.

Melting Ice in the Drain Pan

The outside drain pan, of my Fujitsu 12RLS has frozen. I have left power - ON, (hope the compressor is not damaged) but have turned the Remote Controller - OFF. It seems to ice up when the Dew point is close to the outside temperature (near freezing and extremely cold). Once, near freezing, I was able to 'Cool" and 'extend' the defrost cycle, and melt the ice. Now,at extreme cold, the drain hole is blocked, and ice has built up, to over the top of the pan! I no longer can build enough heat, and 'Cool" the pan and fins, at extreme cold temperatures.

I would appreciate it, if various solutions were posted. I am thinking that a manually (plug In/Out) controlled, base, heater - would be adequate for me. I am not sure, if I should also wrap a cable around the sides, to also clear the fins. I expect to visually watch the melting, before disconnecting the heat.

I am also planning to 'activate' the defrost cycle, nearer to (below) the freezing point, to melt the ice - rather than wait for temperatures above freezing, and turn on the 'Heat' mode.

(I have read about the 'parts availability' concerns. My unit was installed by my son in law, in my remote location - who installs other brands, but is not authorized by Fujitsu.)

MN Mitsu

We are having a colder then expected end to winter here in MN also. But lacking the snow, seems to all go south of us then directly to the NE. Wanted to say this is our first winter with a single Mitzu and love it so far. In a old farm house only partially remodeled and the unit was install to cool the upstairs after replacing windows this past summer and removing Window AC units. The long term plan is to have another on the lower level also. Cooling worked great this past summer, even kept the downstairs comfortable. I also used the same wall mounts as in the photo above and found out that vibration is an issue. Only when we hit -5F or colder, seems like the defrost cycles really rev up. Kind of sounds like a low hum or jet plane flying overhead. Can even hear it in a room across the house when sleeping and everything is quite. So one advice I would give is mount it on 4x4 GT legs like gate posts. Separate from the house structure but could probably be right next to it under a overhang still. This should stop the vibrations. Mine is about 5 ft above ground level. Nice height for servicing etc, also . On keeping up with the cold, last week our original furnace blower capacitor went out and we had only the Minsplit running. Even after 48 hours the minisplit was able to keep the downstairs above 50F, upstairs stayed above 65F and temps dropped to -5 and -12 both nights. So overall happy with the cold temp performance.

Snow buried heat pump

Oh goodness, yes I meant 8 inch ducts. Yes, it would be good if someone could come up with the right figure for the amount of air intake space needed. I dont think moving the unit higher to escape the snow is possible without a complete do-over (expensive) of the installation as there is no extra slack in the parts that go from the unit in through the wall. The snow is 6 feet or more deep back there so it would be crazy high on the wall anyway.

Re-design needed perhaps

I can envision a re-design of these units in which the bottom pan has more slope to the drains and the pan heater is a strip like a heat tape that is not only sensing temperature but conductivity so it knows if there is water/ice there

Response to Kathi Dunphy

Kathi,

Crazy high snow requires crazy high mounting.

The same principle applies to fire hydrants; engineers have developed fire hydrants for snowy climates.

.

How high is "crazy high"?

Remember, in Asia and Europe, it's fairly common for the outdoor units of ductless minisplit systems to be mounted 10, 20, or 30 feet above grade.

.

Just a Thought

I'm planning on using heat pumps for my new addtion and after reading these weather related problems, got me thinking.

Perhaps a dog house type enclosure, with all sides having bird screened louvers, might be a solution.

Longterm fix in progress

I've updated my "ice15" page with a few more fun vignettes, and a

little more info on the heat-pump. Not having a hair dryer handy,

I removed the fan completely from the unit and was able to drop an

*iron* in on various parts of the baseplate and melt out this

go-round's worth of accumulation. This or other creative hacks

might help some of the folks whose units are stuffed...

Running the unit in "cooling" mode without the outdoor fan helped

for a while, and then started throwing "radiation fin temperature

rise" errors as one might well expect [especially with a tarp over

the unit again]. That's fine, I wanted it warm in there! This time

I cleared all the ice from the inside and most of it from the rear.

I now have a single 6-foot section of "easy heat" pipe tape to

play with. It can run in free air and not get hot enough to burn

itself out, so basically anywhere I want to snake it around the

baseplate will get warmed when it's on. At the moment I've got it

coming in *through* the main drain hole, under that fan bracket that

got lifted up, and tucked up against the bottom of the coil over

toward the secondary hole, which should easily hold things for the

rest of the winter. At 42 watts [1 kwh/day] it's not a lot of

overhead to run on the more humid days or when things get plugged

up again, and a more permanent path for it can be designed later.

Heating the entire pan would probably take a lot more power.

Seems like the main thing to keep clear is the drain hole; once

the water is *out* of the unit it's no longer a hazard.

_H*

This is making me feel really good about our installation.

Marc, I'm pretty sure you were the one who advised us to install the compressor under the house with a lot of space underneath it, and I have to say that it's worked out just as well as we'd hoped. We are seeing no ice forming under the compressor, and even with all the snow and all the wind we've had, we haven't had to clear any snow from the compressor. I would have expected the wind to carry snow under the house, but that doesn't seem to be happening.

Thanks Ted!

All time best installation :-)

Yup, Andrea and I have talked

Yup, Andrea and I have talked about what we'd do if we built another highly efficient house, and I think we are pretty well sold on the foundation we chose--I'd be reluctant to go back to a more normal foundation, particularly with in-ground insulation.

pan heaters

At 120 watts, running continuously, that's about 3kwh per day, or about 50¢ at .16 per kwh. Worst case scenario is les than $100 a year. Sounds like cheap insurance to me.

In March, Fujitsu is coming out with more efficient models, designated RLS 3. Apparently, the pan heaters, RLS 3H models, are designed to run only in defrost mode, so the energy penalty should be even lower.

Someone needs to design the perfect enclosure that keeps the snow out but allows enough air circulation. Maybe a code min house just for the minisplits.

My two Fujitsu units with the

My two Fujitsu units with the pan heaters (AOU RLS2H) have been fine all winter here in North Jersey where we have had 25 days around zero or below at dawn and areasonable amont of snow. I mounted them under an 8 ft high deck so they stay reasonably dry. However you mount them you need to look at the clearance requirements for the unit on all sides-you might be surprised.

As someone above said, the next generation Fujitsu and Mitsubishi hyperheat units will likelysolve the issue by having a pan heater that is still very efficient (the AHRI numbers on the new AOURLS3H show an HSFP of 13.8!!!). I understand they are hitting the shelves soon and the online stores are showing them at about the same price as the RLS2H units (e.g., see Younits.com, ACWholesalers.com)

Friedrich Mini-Spli

I installed a unit this January to heat my shop. Yes here in mid Ohio we have had days after day of -14º to 10º temps with blowing snow. I had no other choice but to install on a north side brick wall with the prevailing west winds blowing over it.

After reading every installation manual from every maker, I settled on hanging it 24" off the ground. Now I know why Friedrich does not recommend hanging the unit by a door, the shop door.

Ice, condensation water and ICE. I have none of the ice damage or build up in the unit reported from other manufacturers, My unit drains well and defrosts very quickly. It's under the unit on the ground down the sidewalk and in front of the door, ice build up, that is my only annoyance.

Condensation disposal was covered in great detail for the interior during AC cycle, but not a drop of ink was used explaining the winter woes of heat/defrost cycles on the exterior heat pump side.

That said, old man winter is what it is, cold, mean and unpredictable. Frozen units with ice build up inside, are design issues from the manufacturer. Better installation manuals are also on the manufactures.

How high can you hang them? If you have to bend down to hook up the supply lines, you messed up. If you place it over a sidewalk..you really messed up and will be designing a drain system when spring comes. Do I like my mini-split? It's the best money I have spent in my shop. My attached house is a central geothermal unit, making heat, hot water and AC. It also has a wood stove tied in for supplemental or emergency heat..

Using a mini-split as single source, no way. Get a geothermal unit and keep the compressor inside. Now if you have an addition with problematic ducting issues, add on a mini-split. Mini-splits are not ready for prime time, not with poor insulation manuals, no pan heaters, or lousy drain configurations.

fuj pan heater effeciency

It does seem as Fujitsu has tackled the efficiency problem with their pan heater - unless they are monkeying with the numbers or some other foolery. H models have pan heaters

HSPF

9RLS2 = 12.5

9RLS2H = 8.8

new floor mount models come with a diff model outdoor unit, likely just an update of current models:

9RLFF = 12.6

9RLFFH = 12.4

a note on those mini roofs, etc

If you read the install guidelines, all the minisplit models require open air above of at least a couple feet, which means any sort of roof, especially one mounted to the same wall the minisplit is mounted too would violate the specs.

It kinda makes sense. Unless the unit is mounted far from a building, it must draw a lot of air in from the top/bottom and sides. The ground is a pretty close obstruction for the bottom, and one side is open to coils, so a free and clear top seems necessary.

RE: Melting Ice in the Drain Pan (see above)

I was able to melt the ice, using 'Cool' and high fan, settings, at a o/s temperature just below freezing. I think I am correct - when I leave (place is warm), setting the control at 'Min-Heat' the unit immediately, starts cooling (at the econo fan setting) - rather than 'waiting' or using heat (at the econo fan setting), before, then, maintaining the Min-Heat temperature!

I was unable to activate the 'defrost' setting. I used about 5000 watts of (other) heat and the 'Cool' setting, longer than 4 hours using, the 'fins' heat, to melt the drain pan. I have also determined, at extreme cold o/s temperatures, the defrost time is too short to completely, melt the grill, that surrounds the fins. The defrost setting is automatically activated, but (sometimes) comes on when the unit is turned 'OFF' Turning the unit 'OFF' does not activate the defrost cycle, even allowing 'time for normalizing' at a low heat setting - ice continues to build on the fins.

I would like someone to describe a 'visual' of the Fujitsu, pan heater. I have not yet found a good picture. I cannot determine if the heat cable is outside or inside! etc.

@John

The cable is inside.

Think of it like the heating element in an electric oven. It has thin spacers on it to keep it off the pan to prevent blocking water flow and conducting heat to the pan.

A hot bucket of water will break up thick ice into chunks to pick out (fan off) or melt thin ice; defrosting can't effectively melt the ice in the pan.

The H pan with heater installed has several small think drainage slots, compared to a couple of larger circle holes. Besides the spacers, they use a metallic tape to hold the heat wire down. It's hard to duplicate with the heat tape product as it's too thick and big, but there are a few single wire based products if you're willing to pay for it.

The defrost schedule is listed in the technical manual, there are two programs, a short and a long defrost, triggered by sensors and time limits. It will trigger if scheduled and you shut down the interior unit.

Not sure if your wording is just off, but min-heat function runs the fan on high to help circulate the air to make sure you don't get stagnant areas with low temps. As it only outputs heat around 50deg, the air will feel cool until the temp drops to that point and it starts running heating cycles.

Thanks, Bob Coleman

I appreciate your explanation(s) of the defrost cycle and 'min-heat'. I will need to rethink my o/s unit, as it is over 10' above the ground! (maybe, leave a handy ladder, and configure my o/s hose to be able to also use heated water). I definitely need to be able to melt the ice in the pan. I had the mini-split OFF for several days, until the temperature warmed up. The ice buildup was pushing out the grill, and I thought, might soon touch the fan.

I had not expected 'min-heat' to run 'high fan' until 'heat' was required! Makes sense.

Comments suggest that extended power outage experience is extremely rare. Ours isn’t common, but a week in weather twixt 10 and 20 in an all-electric home makes for cold showers and bed sheets. A minority have installed an auxiliary generator, commonly located in the garage with an exhaust outside, but locating it where it’s heat would be available for the primary unit would seem sensible. Just a thought.

Log in or create an account to post a comment.

Sign up Log in