Details for exterior excavationless foundation insulation

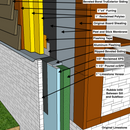

I’ve been following the development of NorthernStar’s approach to exterior insulation using hydrovac trenching and poured closed-cell spray foam, and it seems it would be an ideal approach for our 100-year old deep energy retrofit project foursquare in climate zone 4 (Manhattan, KS). I’ve attached a picture of the stackup we are thinking of using on the foundation and walls, and would welcome any thoughts/feedback on the design.

We have a full basement with 6′ below grade. There is no footing drain on the exterior, though we will be replacing the existing basement slab and adding an interior footing drain, sump, and passive radon system. Gutters and good grading details have been effective at treating bulk water issues in the basement. The soil seems to drain well – last winter we had burst pipes while visiting family, and the foot of standing water in the basement drained away overnight once the water had been shut off.

Our thanks for any advice you can offer!

References to the excavationless exterior insulation approach:

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Regarding the stackup materials:

It's hard to find reclaimed polyiso as thin as 1" (finding factory seconds 1" foam is more likely). But 2" reclaimed polyiso is fairly ubiquitous.

Reclaimed half-inch XPS would be even more rare. What is the purpose of the half inch XPS?

How is the 1" limestone veneer being affixed to avoid sinking/frost-heaving, etc?

Going with 1.5" EPS w/ cementicious EIFS instead of half-inch XPS + 1" limestone might be easier & less expensive. The EPS would be far more rigid, and less likely to bow out under the pressure of the polyurethane pour. A few cap-screws into the foundation prior to the pour would be enough to hold it in place, and the polyurethane would glue the EPS to the foundation.

The aluminum Z-flashing is a significant thermal bridge. EPDM flashing tape is far less thermally conductive.

Nathan,

Like Dana, I'm unsure how you get the limestone veneer to float like that, without a footing or visible means of attachment.

Thanks Dana and Martin,

Interesting. My experience in foam hunting has been exactly the opposite - reclaimed foam sizes below 2" are easy to come by in the Kansas City and Wichita, while larger sizes are scarce. Might be because few jurisdictions in Kansas have adopted/enforce the IECC. I actually already have the polyiso and siding, but have not picked up any XPS.

Swapping the Z-flashing for EPDM sounds like a good idea.

The NorthernStar folks use a 1.5" layer of XPS to serve as a leave-in-place form for a 1.5 layer of poured ccSPF. The poured foam adapts to the contours of the rubble foundation and adheres to both the stone and the foam. They also use furring strips in the pour channel which are screwed into the sill but run down into the trench - which could conceivably serve as an attachment point. I was trying to winnow the depth of the insulating layer to 2" total to keep it in plane with the above walls, but could certainly alter the ratio and composition of the two layers.

We're trying to preserve the historic look of the house (hence the beveled siding), and reproducing the appearance of a limestone foundation is an important part of that. I have an experienced stone mason who tells me he has had good success installing thin veneer cut from local quarries directly on foam - particularly Insulated Concrete Forms, but I don't know the details of his method.

Nathan,

Have you considered using a stencil to make the stucco look like brick or stacked stone?

Steve,

It's a good thought, but I'm not sure I can find a contractor in the region with enough knowledge to pull it off. Stucco is not a common finish in our area, and I've never seen stenciled stucco anywhere around here.

Dana,

On the EIFS, were you suggesting keeping 1" of poured ccSPF, a 1.5" layer of EPS, and then a layer of synthetic stucco? How thick would that layer be? Would it need a layer of wire mesh?

The thickness of the EIFS layer and whether it needs mesh depends on the product used.

On the thinner-easier side, Quikrete Foam Coating is designed to be applied directly to EPS or XPS (no mesh), and can be spray applied or troweled. Minimum recommended thickness by the manufacturer is 1/4" ( not sure what the maximum is, if any). Depending on the appearance you're seeking it can be troweled to a nearly shiny uniform flat finish, or textured to look like a rough or trowel patterned stucco. There are probably ways to give it a sandstone surface roughness too- it's all depending on the artistry of the person installing it. It comes in two colors- gray or white. If you have a particular brownish (rather than gray) limestone color you're trying to match there may be ways to add coloring agents to the mix or stained after it has set up some, but you'd have to consult the manufacturer to know if there are preferred or "no go" products to use with it. It's pretty rugged stuff, even at 1/4", probably due to fiber reinforcement in the mix.

Nathan,

Q. "On the EIFS, were you suggesting keeping 1 inch of poured ccSPF, a 1.5-inch layer of EPS, and then a layer of synthetic stucco? How thick would that layer be?"

A. Most homeowners' insurance policies, as well as the standards of the EIFS industry, require EIFS to be installed by a certified contractor. This isn't a finish that can be installed by an uncertified contractor, with varying specs. So call up a certified EIFS contractor for details.

For a full list of all of the materials that can be used to protect above-grade rigid foam installed on the exterior side of a foundation wall, see this article: "How to Insulate a Basement Wall." (Scroll down to the heading in a bold font that reads, "If I insulate on the outside, how should I protect the above-grade foam?")

Dana or Martin,

What if the outer layer was cement backer board, with a 2" layer of ccSPF poured behind it adhering the backer board to the rubble foundation? I could brace the backer board like a concrete form to prevent blowouts - it would only be a 2' tall layer above grade. It seems like this would essentially be a site-built version of the Pro-Guard insulated concrete board mentioned in Martin's article.

Do you think that would offer enough rigidity and support for a layer of thin stone veneer? Would mechanical fasteners into the sill & rubble foundation be necessary?

Nathan,

There are lots of kinds of stone veneer and artificial stone (concrete that looks like stone) veneer.

In general, thicker veneers need a brick ledge or concrete footing for support. Many types of stone veneer also require brick ties for stabilization.

Some types of very thin stone veneer can be attached with adhesive. Whether or not this approach is permissible on sub-slab rigid foam that is several inches away from a concrete foundation depends on the installation details provided by the veneer manufacturer. So you should contact the stone veneer manufacturer with your questions.

Most tile backer-board is NOT rated for exterior use, and is likely to suffer freeze/thaw spalling or other degradation in your location. Read the specs carefully before going down that path.

Hello Nathan,

Did you ever complete the excavationless insulation project? I have a similar home in STL and was wondering if you were able to find a hydrovac/insulation company in the area to do this work (with experience).

We haven't yet - it will be the final step in a long-running staged retrofit. I have seen Badger Hydrovac excavating against the foundations of a recently constructed apartment complex in town, for more traditional work (looked like they were unearthing some of the services to work on), and they have a unit in Kansas City. But I suspect any hydrovac crew could pick it up quickly. I'm more concerned about finding a spray foam contractor willing to do the pour.

It might be hard to find pourable foam with HFO or other low-global-warming potential (GWP) blowing agents--they probably use the high-global-warming HFCs still. If you see an ad that says "zero ozone depletion" without mentioning GWP, that's a tip-off that it's HFC and has >1000X worse global warming potential than CO2.

Hi there,

I’m in the same boat with my home in St Louis, a 1950’s slab-on-grade ranch in Olivette. Just wondering if you’ve gotten any further. We should connect and share resources.

Bert Berla