Image Credit: Image #1: Greg Labbé

Image Credit: Image #1: Greg Labbé The house in the middle is “just right.” It was commissioned to confirm that the ventilation system was balanced – that is, the pressure inside the house is the same as outside. The house on the left has a supply-only ventilation system that is pressurizing the house, whereas the house on the right with an exhaust-only system is pulling in cold dry air from the outside when it’s on. [Image credit: Venmar]

Image Credit: Image #2: Venmar A typical laboratory setup for testing HRVs and ERVs. The ductwork includes flow straighteners with nice straight lengths of duct before the taps. In the field, an ERV or HRV never looks like this. [Image credit: NRCan]

Image Credit: Image #3: NRCan This photo shows a typical HRV installation. For those who need to perform commissioning tests, access to the ducts isn't great, but it's OK.

Image Credit: Image #4: Greg Labbé On the job describing in this article, stations 1 and 4 were the same shape. We taped the cardboard flange to the perimeter of the vent in order to get a reasonably good seal with our balometer. The backdraft dampers were not in the hood but in the duct. Three sequential measurements were taken to account for potential errors due to wind.

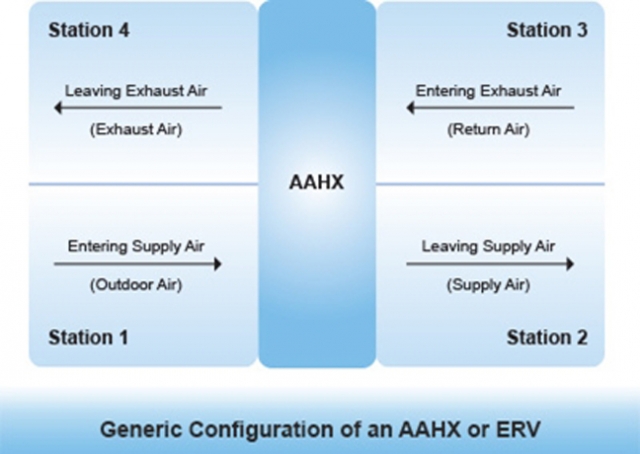

Image Credit: Image #5: Greg Labbé The numbers shown here are clearly for a commercial ventilation system, but the illustration shows the relationship between air flows. [Image credit: Venmar]

Image Credit: Image #6: Venmar In the end, we went with our DG700 and measured the pressure across the building envelope to ensure the system was ‘balanced’ when the ERV was running at TSV. CSA F326 states that flows in and out must be within 10% of each other and typically the flows are measured at stations 2 and 3 if the duct work will allow.

Image Credit: Image #7: Greg Labbé

We were recently called to commission a fully ducted energy-recovery ventilation (ERV) system in a newly constructed, “near passive” house.

Commissioning an ERV usually involves dialing in the specific ventilation rate on the variable control knob, and then adjusting air flows room by room according to the intended mechanical design. We also needed to ensure that the system didn’t change the pressure in the house with respect to the outdoors. At risk of stating the obvious, mechanical ventilation systems will either pressurize or depressurize a home if not commissioned properly. (See Image #2 at the bottom of the page.)

What we thought was going to be a straightforward job turned into a multi-day time-gobbler that taught us a few lessons.

Following a standard for commissioning the system

Fortunately, none of the appliances in the home were susceptible to combustion spillage: there were no CO2 sources (wood or fossil fuel appliances) and there were no exhaust-only appliances that depressurized the house (i.e., no bath exhaust fans and no range hood exhaust fan; the clothes dryer was condensing).

We intended to follow the commissioning process described in a Canadian ventilation standard: CSA-F326, “Residential Mechanical Ventilation Systems.”

In Canada, ventilation systems can be designed to meet the building code or as an alternative to comply with CSA-F326 (the case for this meticulously designed mechanical system).

CSA-F326 requires the installer to certify that the ventilation system installation complies with the standard by filling out “Form A,” which in turn can be considered by building officials as a performance certificate. Our first job was to figure out the Total Ventilation Capacity (TVC), and then to balance the room-by-room air flows. The standard is very forgiving in that it allows for ±15% on the TCV measurement and ±25% on room-by-room air flow rates when compared to design values (1).

Few designers or installers of residential ventilation systems plan for commissioning. Typically the HRV or ERV is tucked high into a corner of the basement mechanical room, with flex-duct contorted and crammed on all four stations.

The Air-Conditioning, Heating, and Refrigeration Institute (AHRI) labels the HRV port for entering outdoor air as Station 1; the port conveying fresh supply air to the house is referred to as Station 2; the port bringing stale air to the HRV or ERV is referred to as Station 3; and the port that conveys stale air destined to be exhausted to the exterior is referred to as Station 4.

The Heating, Refrigeration and Air Conditioning Institute of Canada (HRAI) suggests that the best place for flow collar placement is on the warm side (at Stations 2 and 3), before any branches. When it comes to accurate measurements of air flow, doing a transverse with a Pitot tube comes in third. The second-best approach is to use the more convenient insert-type linear flow measuring station. Of course, the best method is to install a four-quadrant flow measuring station, despite the labor involved.

The house in question didn’t have ideal places to install our four-quadrant flow sensors. Having recently invested in a pressure-compensated balometer which I hoped would earn its keep, I decided to measure at Stations 1 and 4.

What’s the error range?

When I spoke with the top scientist at ACIN Instrumenten (the manufacturer of the balometer) in the Netherlands about our proposed method using the FlowFinder Mk II, the scientist suggested that the error of the method could be a bit higher than 3%. Given the alternative, that sounded acceptable and well within CSA-F326 10.2.1′s suggested ±15% for a quick and painless “no-tin-snip and tape” commissioning. This was progress!

Stations 1 and 4 were the same shape. We taped the cardboard flange to the perimeter of the vent in order to get a reasonably good seal with our balometer. The backdraft dampers were not in the hood, but in the duct. Three sequential measurements were taken to account for potential errors due to wind.

Armed with flow-measuring stations, Pitot tubes, and our new balometer, we started measuring to find where our TVC might be on the variable-speed control board. This would then allow us to adjust flows room by room — except that the flows in and out of the house were off. Way off.

What’s going on?

Because of constrained access to Stations 2 and 3, the flow collars wouldn’t have made sense, so we had to use a Pitot tube, and the numbers were not reliable. So we took apart the ductwork to check whether the inline dampers were OK. There were no adjustable air flow dampers for this ERV.

Then we dove into the manufacturer’s manual to change jumpers on the mother board to offset one of the two fan motors. Still the flow rates were impossible. We were getting in some cases over 100 cfm more exhaust air (at Station 4) than outdoor air (at Station 1), and no HRAI ventilation course could have prepared us for what we went through.

The technical literature suggested that it was common for an ERV with a heat transfer wheel to mix in extra “purge” air to combat cross contamination — which might explain our difficulties. In this case, the heat transfer wheel was cut into pie-shaped pieces that fit in walled slots that aim to reduce the cross contamination. It should be noted this particular brand of ERV is quite common in high-performance homes in Ontario, and those who have them love them. We’ve had a previous experience commissioning the same model without such a large spread.

A defective control board

In the end, common sense prevailed. Using a watt meter, we diagnosed that something was the matter with the control board. The board was replaced and in the end, flows in and out were within CSA’s spec for the TVC.

By design, this meant that air flow at Station 1 wouldn’t equal air flow at Station 4. The ratio between those two air flows is called the Outdoor Air Correction Factor (OACF), which ideally should stay as close to 1.0 as possible.

There’s another cross-contamination measurement called the Exhaust Air Transfer Ratio (EATR), which is the ratio of the exhaust air transfer to the supply flow rate. The ERV in question was laboratory tested in general accordance with CAN/CSA-C439-00, “Standard Methods of Test for Rating the Performance of Heat Recovery Ventilators.”

The ERV wasn’t listed as HVI-certified (or AHRI-certified if a commercial unit). The OAFC wasn’t available, but the EATR was calculated at 0.09 by the manufacturer, which translates to about 3% of the exhaust air being transferred into the fresh air stream. In other words, if we wanted 100 cfm of fresh air delivered, we’d have to bump it up to 103 cfm; but that wasn’t consistent with our measured findings in the field. This might work in the lab, but not in the field — where we were getting differences of 100 cfm, possibly due to a large OACF, or possibly due to the home’s unique custom ductwork or the added resistance of a pre-heater (see Image #3, below).

Deriving the Total Ventilation Capacity

In the end, we derived TVC by adjusting flows room by room, and then simply ensuring the house pressure was neutral at TVC (see Image #7, below.) Having witnessed the build at the bare duct stage, we knew duct leakage wasn’t an issue, though we could have tested for it.

The lessons learned included:

- Ensure that the mechanical designer selects an HVI-certified or AHRI-certified model; and

- Ensure that the heat exchanger core uses an airtight membrane that prevents cross-contamination.

-

It also makes sense to work with the designer to ensure that the flow measuring stations (Stations 2 and 3) are specified in the design and are clear of turbulent features, and to communicate that requirement to the installer (see Image #1 at the top of the page). Though it probably applies more to commercial systems, Venmar suggests, “If OACF is ignored in the selection process, then the prescribed amount of fresh air will not be supplied to the space and poor indoor air quality may result — in addition to creating numerous potential issues with balancing and commissioning.”

For a thorough treatment of the calculations and more explanation of the jargon used above, see AHRI’s “How ERVs Work” section; it is brilliant. I’d also recommend downloading and reading NRC’s pdf for insights into the testing process: “Evaluation of IAQ Impact of Balanced Residential Ventilation devices that incorporate HRV and ERV.”

Footnote

1. Discussing the topic of excellence, Aristotle suggested that “It is the mark of an instructed mind to rest satisfied with the degree of precision which the nature of the subject admits and not to seek exactness when only an approximation of the truth is possible.” This observation is useful when considering whether to use the garbage bag test or a Flowfinder.

Greg Labbé is co-owner of BlueGreen Consulting Group, a high-performance home consulting firm that works with architects, builders, and homeowners to optimize the energy performance of new and existing homes through detailed energy modeling and site testing.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

2 Comments

Great article, Thanks! I would like to add that we had an experience with our HRV system installation. The installation aligns with your proper design balances. The installer connected the excess moisture drain tube from the HRV system to the house septic vent stack to avoid having a separate penetration in our Net Zero house. He forgot to charge the “P” trap with water and we spent our first months wondering where that dead animal smell was coming from on occasion. He could not assess it even though we were at the unit and getting ready to look into all ducts with a scope. I was able to clearly isolate the issue to the HRV (not the HVAC) systems (we have 2). Once that was done, i went over the design as installed and then when I saw the empty “P” trap (clear plastic tubing looped and anchored to make a “P” trap), it hit me over the head, DUH!. The question to answer was; “when does a fresh air system deliver air that smells like s***?”. Once the tubes were charged, you could see that the system pulled a light vacuum as shown by the visible tube water level change. A small detail that had big performance issues.

I have recently started a job with a Nebb certified company. I estimated time to measure all 4 inlets and outlets as specified on the plans. When it was reviewed by the owner he stated that we dont need to measure the outside supply and exhaust as the inside measurements would prove these. I questioned him on duct leakage between the 2 outside and inlet grills and he proceeded to explain you can just hold your hand up on them. Having installed flex duct I queried about a duct having pulled off at the top and unless you measure you cant be sure unless you measure the outside grills. Am i correct as far as nebb standards are concerned when l/s measurements are specified on the drawings?

Log in or create an account to post a comment.

Sign up Log in