ZIP Attic Floor Sheathing and Vapor Barrier

I contacted Huber Engineered Woods LLC about using ZIP sheathing for the attic floor and then taping it to the ZIP exterior wall sheathing in order to create an air tight enclosure between the main floor and the attic. I explained that the attic was vented and there would be 16″ of Roxul Comfortbatt sitting on top of the ZIP attic floor sheathing (the roof load will be supported by trusses).

I asked the rep about using a vapor barrier either above or below the ZIP floor sheathing and he said: “I would not recommend installing any type of vapor retarder in the ceiling, rather I would allow moisture to rise into the attic and properly install the necessary baffles and ridge venting to manage the vapor movement”.

Wouldn’t the fact that the ZIP sheathing was airtight prevent the movement of vapor from the warm main floor into the attic? I was thinking of maybe adding Membrain as a back-up vapor barrier to the ZIP sheathing but wasn’t sure where to put it – either above or below the ZIP floor sheathing? Or not at all?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Your roof should work fine, but there is no need for ZIP there, you'll never see any water (or shouldn't) so there the WRB is unnecessary. Go for either standard OSB/CDX and tape them the same as ZIP.

As for vapor barrier, that will depend on your local code. It really doesn't matter if you have one or not, a well sealed assembly will work just as well, but your inspector might disagree.

P.S. Blown in cellulose is much cheaper and more environmentally friendly than mineral wool.

The reason I picked ZIP for the attic floor sheathing was becasue of Matt Risinger's Monopoly house design.

https://www.youtube.com/watch?v=Qhs52h8f51Q

He's basically building himself a ZIP "monopoly box" by connecting the ZIP roof sheathing to the exterior wall sheathing to create a completely airtight assembly. The main difference between his design and mine is that his house has a conditioned attic and my attic is vented to the outside.

So that being the case I thought I would make the main floor of my cabin a true "box" and wrap it in ZIP sheathing and then add the attic trusses and roof sheathing afterwards. My goal is to have a really air tight main floor and let the roof sheathing handle the water.

I would love to have blown in cellulose but I'm out in the middle of nowhere and a truck couldn't get in.

>I would love to have blown in cellulose but I'm out in the middle of nowhere and a truck couldn't get in.

Blowing cellulose is easy, unless you go with dense-pack or wet. Everything you need for regular can be brought in the back of a pickup truck.

At my local Home Depot, 7/16 Zip board is $36.85. OSB in 7/16 is $20.75. In this application Zip offers no advantage.

With the vented attic the "Monopoly" style isn't what you want. The whole idea is that you have a continuous building envelope. With a vented attic the floor of the attic is the building envelope. So you want the floor of the attic linked to the sheathing of the exterior walls. Once you've done that you can have a conventional roof with overhangs that sits on top of the attic floor.

You don't say what climate you're in. Where the vapor barrier goes depends on the climate. Very generally, in a heating-dominant climate you want the barrier on the inside of the envelope, in a cooling-dominant climate you want it on the outside.

Water vapor can move through materials.

ZIP is an all-in-one product with what is essentially a fluid applied WRB applied directly to the panel. This WRB, like housewrap, is designed to prevent bulk water from getting into the sheathing.

In any case your approach to air sealing the attic with ZIP has been done before. GBA blogger Carl Seville used your approach on his home in Georgia.

https://www.greenbuildingadvisor.com/article/topping-out

(Click on the photo gallery)

This approach, placing the AB at the attic floor, was also proposed and discussed in the first several comments of Martin’s blog https://www.greenbuildingadvisor.com/article/airtight-wall-and-roof-sheathing

And in the comments of Lstiburek’s https://www.greenbuildingadvisor.com/article/lstibureks-rules-for-venting-roofs

I wonder whether John Brooks ever ended up using this approach?

You are thinking "if I use X, it will be airtight". I suggest that you will be much better off with "if testing verifies it, it will be airtight".

Thanks for everyone's advice. I'm in climate zone 6b so cold and dry. Or "drier" than 6a.

I was thinking that since the ZIP sheathing, has a fluid applied WRB coating it would be better for the attic floor than OSB, or is it? If vapor can move through OSB can it still move through ZIP?

Since there wouldn't be standing water or rain hitting the attic floor, if I do use ZIP for the attic floor sheathing should the WRB side face up into the attic or down towards the warm main floor interior?

Water vapor will diffuse through OSB/Plywood and all forms of housewrap. Reason being that you don't want to prevent a wall from drying out in at least one direction (exterior/interior ). It is why these products (ZIP, OSB/plywood w/housewrap) are used on walls. They are and were not designed to be vapor barriers.

Anyways Climate zone 6b may or may not required a vapor barrier in the ceiling. Per Joe (see link) it should only be used when you have 8,000 heating degree days or more. Not all of CZ6b falls within that criteria.

https://www.jlconline.com/how-to/insulation/q-a-ceiling-vapor-barrier-yes-or-no_o#:~:text=Plastic%20vapor%20barriers%20should%20only,than%208%2C000%20heating%20degree%20days.&text=Omitting%20a%20ceiling%20vapor%20barrier,also%20incorrect%2C%20in%20a%20way.

> I was thinking that since the ZIP sheathing, has a fluid applied WRB coating it would be better for the attic floor than OSB, or is it?

Interesting factoid: the coating on Zip is not fluid applied. It is a sheet good that is bonded to the panel as part of the pressing of the OSB panel. Heard this from Allen Sealock of Huber who was on an episode of the Unbuild It podcast (https://unbuilditpodcast.com).

In 6b you want the vapor barrier on the inside.

I don't quite get what you're trying to do though. Normal practice would be to have a ceiling, then insulation above the drywall between the joists, and then more insulation above the joists. Vapor barrier would go between the drywall and insulation. You don't need anything above the insulation. Maybe if you have soffit vents you'd have some kind of blocking to keep the insulation from being blown around. If you want to be able to walk in the attic then collar ties between the rafters and planks over them.

If you're attic is vented you're not building a monopoly house, you're building a beer cooler -- which is actually simpler. You don't have to worry about tying the roof to the walls.

If the object is to connect the air barrier overhead to the one in the walls, it is a lot easier to hang the osb/zip from the trusses. Before trusses are set, install a 1 foot wide x 8 foot piece of taped zip on top of the cap plate (also include whatever you need to tie the barrier to the wall barrier). Install trusses and fill the rest of the ceiling with zip.

The big advantage of zip is that their tape will stick to it. Good luck getting any tape to stick to raw USB. I haven't tried priming it first though.

This is how we did the air sealing on my house, with Perfect Walls. The outside wall membrane tied into the zip system overhead.

We have 10 foot ceilings, but dropped them to 8 in some areas to accommodate venting ductwork, electrical, and plumbing. (We are on a well insulated slab therefore everything went overhead).

If we wanted ceiling light fixtures in our 10 foot rooms, we dropped the ceiling 1 1/2 inches.

Our method of dropped ceilings required lots of fire blocking in the walls.

I’m planning something very similar. I think this article from JLC explains what you’re trying to do. https://www.jlconline.com/how-to/insulation/an-airtight-lid-the-easy-way_o

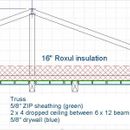

Daniel, thanks for the link to this article by Ted Cushman. My plan is slightly different from the article in that I was going to put the ZIP sheathing on top of 2x4's installed between 6x12 ceiling beams rather than building a 2x10 floor system (I still get the ceiling cavity to install wiring and lights though). I also plan on using a raised heel truss for uniform insulation levels over the exterior wall rather than a stick built roof.

I will tape the ZIP attic floor panels to the exterior wall top plates and then run ZIP wall sheathing up past the top plates and attach it to the ends of the high heel trusses to help secure the trusses to the walls. This should give me an airtight building assembly as well as a very strong structure.

His idea is the first image, my idea is the 2nd. Thank god for cut and paste :)

Why tape the attic deck to the top plate? Don't you want to tape the deck to the interior of the wall sheathing that you are extending up past the top plate, i.e. your exterior air barrier? There will be gaps between the taped top plate and the exterior sheathing where air exchange between the attic and the stud bays can occur. What is the sequence of work with regard to sheathing the wall and installing trusses? Walls sheathed before trusses installed as is typical for conventional rafter framing?

Also don't understand why you want to spend more on ZIP sheathing for an interior exposure.

Scott,

Gotcha! Love the revised graphic! Maybe you can come back to this post and post some pics of your assembly once its installed! I think the idea is sound for both variations of the application, and I’m still planning on adapting it for our build. Thanks for sharing!

David: Taping the attic ZIP sheathing to the top plates should air seal that joint. I will run a bead of sealant along the outer edges of the top plates before I apply the wall ZIP sheathing. That should close up that joint.

The building process will be:

1. Main floor walls and lower courses of ZIP wall sheathing

2. Main room 6 x 12 cross beams

3. 2 x 4 infill dropped ceilings

4. ZIP attic sheathing

5. Seam and edge taping

6. Attic trusses

7. Wall top plate sealant

8. Top course of ZIP wall sheathing overlapping wall, top plates and truss ends

9. Roof ZIP sheathing

10. ZIP under eave sheathing

11. Tape ZIP roof, eave and wall seams

The ZIP attic floor sheathing will be both the air and moisture barrier (which I think is better than just using OSB), although I might add a Membrain sheet below the ZIP attic floor sheathing for extra protection.