Adding Xypex to Concrete Mix for Footings

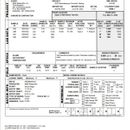

Instead of fooling with a capillary break, I’ve decided to add Xypex to my concrete mix. Having very minimal knowledge of concrete science, I asked for compression tests. Here are the variables:

Molded four (4) cylinders. Engineering/Lab company called Bowser-Morner Inc.will break the cylinders. (2) cylinders for seven (7) day compressive strength testing and two (2) cylinders for twenty-eight (28) day testing.

I’ve receive my first test back. This is a 7 day cure test.

It came in around 4000PSI. That seems fine to me, but I really don’t know any better.

Can any of you experts comment whether or not I’m doing ok with my mix? Does anyone see anything that might raise a flag. From what I interpret everything seems fine and I’m smiling.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

That mix looks fine to me. 4K psi is plenty strong enough for pretty much everything residential, and it'll only get stronger over time. It's hard to say more without the sieve analysis of the fine and coarse aggregate, but at the end of the day the properties of the finished product are what matters more than the ingredients. It's got enough entrained air to help resist freeze thaw, so I'd call it good.

On a side note, It looks like it has a SCM of ground blast furnace slag, which is supposed to help decrease ion permeability, and eventually have a higher strength gain than OPC when added, but I think it's highly dependent on how well it's been cured.

Drew,

If anything Xypex increases concrete mix strength. It does slow curing, so if you are already getting 4000psi at 7 days you are more than good.

Drew,

I used Xypex for footings and all walls to control moisture rise due to spring runoff that tracks the sandstone I am built on. I have to admit I did not question the compressive strength effect, but I did make sure to mist the foundation twice a day to ensure a good cure due to the Xypex additive. Where I live has quite low humidity in the summer, so once the forms were stripped the surface dried in a flash. It may be a mistaken belief, but I was concerned that the additive might further tie up the water needed to cure the concrete. The misting was sucked into the wall so fast that I made sure to complete a week of treatments.

I can only guess that my efforts were valid. The walls and footings have performed as anticipated, which has ensured my basement shop is very dry. I can even leave sheet goods against the wall without fear. I intend to spec Xypex additive in my next build as the foundation will face the same conditions. If you live in a similar dry location you may want to consider helping the curing process with misting after the forms are stripped.

Thanks all.

Roger - Forms were stripped 9 days ago and we experienced near-record heat for June 1st reaching about 92° in Ohio. I was concerned precisely with what you're explaining but I have no water on site. It was hot and sunny for 3-4 days after stripping, then fortunately we have had a couple of downpours and some sprinkles here and there since the forms were stripped. The new problem is that it's all clay in this area and the excess water is causing the walls to cave in towards the foundation. I'm told a week's time is sufficient to wait before backfilling but I don't want to press it. Since the curing process is slowed per Malcom's comment, I feel better about my decision to wait. I did lay down about 1 foot of washed stone over the tile and just that little bit makes clean-up easier after a cave-in occurs. I've had about 6 or 7 cave-ins. Now the latest problem is my back! Shoveling hunks of clay the size of a refrigerator isn't much fun.

Anyway, I've learned quite a bit from the couple replies here, and that's what it's all about. I appreciate your responses.

For anyone's interest, I posted my 28 day results. One of the samples peaked at 5690 PSI.

I'll take it!

Drew,

Good and then some!

I was also considering adding xypex. My experience with it was when we performed repairs on a concrete structure in the woods, it’s purpose was to contain a spring, and channel the water to several homes for drinking. As such, we were limited in which waterproofing we could use.

I think it would be neat to take humidity measurements in buildings with xypex foundations, and those without.

Very interesting info, thank you.

Ben