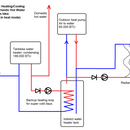

Would this radiant heating/cooling + DHW setup work?

I am in Montana (zone 6) and wondering if this system would work. I am trying to avoid overly complicated pieces of equipment, like combi-boilers. Since my groundwater is 36 degrees in the winter I will need a powerful gas tankless water heater for domestic hot water (199,000 BTU). I would like an air to water heat pump for radiant heating/cooling but will definitely need a gas burning backup for the -30 F we get every winter. I see that a lot of people use a Polaris water heater as a backup to the heat pump on cold days, but those are very expensive for something that will only run a few weeks a year. Since I will already have a powerful DHW tankless heater that will be on standby for most of the day, I thought it could also serve as the backup for space heating when it gets too cold for the heat pump.

Are there any problems with the system in my drawing?

Any recommendations for a simpler system?

I have no idea what thermostat/computer controls will be needed to run all of this seamlessly. Any recommendations for brands of heaters or controllers?

Thank you.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

There's no benefit to using an air to water heat pump to heat domestic hot water over just having a heat pump water heater inside the building. So that would simplify things greatly.

In your climate I would look closely at the cold weather performance of the heat pump. That 60K BTU/hr nameplate capacity isn't going to be available when it gets down below zero, you'll be lucky to see half of that.

Generally air-to-air have better cold weather performance.

If you go with air-to-water, due to the way their control mechanism works you won't be able to supplement with the propane boiler, you'll have to run one or the other, you can't run both at the same time. That does somewhat simplify the control, you just want to have a temperature where you shut off the heat pump and turn on the boiler, and vice versa.

You can run both at the same time, maybe not the chilltrix though.

I'm not aware of any heat pump that runs at temperatures typical of boilers.

I'm not aware of any heat pump that runs directly off of a house thermostat, rather than using the temperature of the water to trigger whether it runs.

There are going to be two decision points. At a certain temperature, the COP of the heat pump will drop so low that it is more cost-efficient to run the propane boiler. Also, at a certain temperature the output of the heat pump will drop so low that it can no longer cover the heating load. Where those points are depend on a lot of factors, including the climate, the heating load, the sizing of the equipment, the relative cost of electricity and propane, and so forth.

If the first point is warmer than the second point, you just want to switch over when you reach that point. If the second point is warmer, in theory you could save some money by getting as much heat as you can out of the heat pump until you reach the first point, and then only using the boiler to contribute the shortfall between the heating load and what the heat pump can provide.

The problem is that in that scenario you want the heat pump running full out. Since the heat pump is controlled by the water temperature, if you heat the water warmer than the cutoff for the heat pump, the heat pump will shut off. For high COP you typically run at rather low water temperatures, like 100F, so the boiler can't be heating the water any higher than 100F. That's doable, but it's going to mean tempering the water with a mixing valve.

I think you're going to be better off just turning the heat pump off and switching over to the boiler at a given temperature. It kind of depends on the size of the band where running both might be economical, but my suspicion is that in a place that regularly sees -30F that band is going to be pretty small.

If you just switch over, you don't have to size your emitters for low water temperatures, you can size them to whatever the boiler can produce on the coldest days. You'd also size them for low water temperature in the outdoor temperature range when the heat pump is expected to be running.

Think of warming the return water - 100 to 120F then the boiler tops it off. They’d both run simultaneously. It looks like this is a floor application so temps won’t be a problem.

The whole point of trying to run both is that the boiler only provides that which the heat pump can't provide.

So let's say the HP thermostat is set to 100F. The water coming off the heat pump is at 95F. How does the boiler know whether that's because the heat pump can't keep up, so it needs to fire up, or because the heat pump has sensed that heating load has been met and the heat pump has turned off?

If the boiler is warming the water after it leaves the heat pump, how does the heat pump sense whether the heating load has been met?

Who's in charge?

Chiltrix has an option where you can have the heat pump controller turn on a backup resistive electric heater if the heat pump can't keep up. Probably your best bet would be to try to get that to work with a propane backup.

But again, I think the band where it even makes sense to run both is going to be so narrow that it's not worth the complexity.

This is exactly how the Tekmar 406 works. My configuration most closely matches A406-2 on page 13 of the installation manual (https://www.watts.com/dfsmedia/0533dbba17714b1ab581ab07a4cbb521/42881-source/406-d-03). The electric boiler just handles what the heat pump can't. So the only time the electric boiler is running and the heat pump isn't are when outdoor temps prevent the heat pump from running at all.

Tekmar shows applications with gas boilers. I expect the challenge with gas is controlling short cycling if all you have are low-temp radiant loads, but I'm sure it could be designed.

I was planning on using the air to water heat pump only for space heating (and cooling if I can figure out how to add dew point controls). Therefore it couldn't be used to heat DHW when I am trying to cool my house with it.

Good point on the drop in performance on colder days. Thank you.

Do you know why air-to-air is better than air-to-water? I thought water was a better heat transfer medium because it has a higher specific heat capacity.

I'm not sure why I couldn't run both the heat pump and tankless unit together since they are collecting the heat indirectly in a large buffer tank and they do not interact directly with each other.

"Do you know why air-to-air is better than air-to-water? I thought water was a better heat transfer medium because it has a higher specific heat capacity."

In an apples-to-apples comparison, air-to-water always gives a higher COP, because with air-to-water you can have lower output temperatures, and COP is highly dependent upon the difference between source temperature and output temperature.

The problem is that air-to-water is a niche market, so technological innovations get there slower. So technologies like vapor injection are common in cold weather air-to-air heat pumps but haven't really made it into the air-to-water market.

It will be interesting to see what happens at the end of this year. My understanding is that the EPA has mandated that manufacturers cease selling equipment that uses R410A as a refrigerant. This means everyone is going to have to roll out completely new product lines. This will force air-to-water manufacturers to leapfrog technologically.

I think you need to reevaluate a few parts of this:

1. You don’t need a tankless water heater, period. I would highly recommend skipping the tankless water heater, they’re inefficient and low performing. An indirect is higher performing and you’re already including it.

2. I’d go with a low efficiency, simple boiler as the DHW and central heating backup. So the air to water heat pump would heat DHW and CH, and the cast iron boiler would operate as needed. My thinking is that central heating is more important, so instead of turning a DHW heater into a central heater, you use a central heater as a DHW heater via the indirect.

3. Right now you have an indirect tank in your drawing but it looks like it’s being used as a buffer tank. Do you need a buffer tank? With radiant floors, the answer could be no. There is a product called a reverse indirect, which is buffer + indirect in one but ideally you could get away with just an indirect.

1. I might be using the wrong name but when I say "indirect water heater," I am referring to just a large tank with a heat exchanger coil inside. There isn't any heat source in that unit. I am referring to something like a Triangle Tube Cardinal or a Lochinvar Squire.

2. That makes sense, however I was hoping to use the heat pump for radiant cooling and therefore it wouldn't be capable of cooling the house and heating DHW at the same time.

3. I was using the tank as an interface between the (heat pump + radiant heating/cooling) and the (DHW + radiant heat backup) systems. I want to run the space heating system as a closed system at lower pressure with glycol. I could just separate space heating from DHW entirely except that I then need another piece of equipment, a gas fired appliance for space heating when it's too cold for the heat pump. Something like a Polaris heater is perfect for this but rather than spending $5,000 on a Polaris I would rather just buy a $1500 heat exchange tank and use the DHW heater to heat it. This would reduce the number of appliances, reduce complication of venting, and reduce cost.

An indirect tank is just not well suited to an air-to-water heat pump.

There are a lot of old hands at hydronics who view air-to-water heat pumps as just like boilers, only noisier. The idea of getting hot water out of them comes from that mindset.

The indirect is piped wrong. Both the boiler and the heat pump should heat the coil. The tank itself will hold potable water.

The heat pump should definitely be heating the water in summer. It’s very simple for it to switch over.

The heat pump and boiler would both be low pressure. Just delete the tankless, it’s complicated and inefficient.

In summer, a heat pump water heater would contribute free cooling to the house.

I'm not aware of any residential air-to-water heat pump that captures waste heat in cooling mode for domestic hot water. The ones I've seen stop cooling and switch over to heating mode. If you're doing that you're better off just pulling the heat from inside the house with a HPWH.

I have seen geothermal systems that capture waste heat. The problem is there's no guarantee the need for cooling is going to align with the need for hot water, so they just use it for preheat and have a separate dedicated hot water source.

The Nordic does. Anyway, air to water + boiler is the way, not a tankless. The DHW can be a HPWH. It doesn’t need any sort of backup.

The Nordic has a desuperheater that does pre-heating, like the geothermal units I mentioned. You still need a separate appliance to meet the rest of your needs.

I would think the cooling from a HPWH would have minimal effect in the summer (especially placed in my basement) and in the winter it would work against me. Also, I specifically wanted a gas tankless water heater for DHW since I have a bathtub and would enjoy the "endless hot water."

I am not trying to use waste heat from the heat pump (it's outside). I am just trying to use my DHW tankless unit as the "backup boiler" for my radiant heating since it is already capable of producing plenty of heat and will be already there on standby most of the day.

Paul, you keep mentioning that I should add a boiler, but remove the tankless. What is the difference?

You can do this with a MuliAqua: 5 ton unit - https://multiaqua.com/mhrc2/

To reply to #15: A boiler is just heavier duty product.

The “endless hot water” is just hype. Capacity is capacity, nothing special about it being tankless. A tank will be higher performance all else equal.

Also replying to #15, a HPWH installed indoors does not “work against you” if your space conditioning is also some kind of heat pump. You move the heat twice, but the heat still comes from outside. There is a post from DCcontrarian that covers this in some detail: https://www.greenbuildingadvisor.com/question/where-is-the-most-efficient-place-to-get-the-heat-for-hot-water-from

The simplest solution would be electric heat backup, it's cheap, small size big capacity, and since it might only run a short time every year you might not feel it on your bill anyway, and it's simple enough almost nothing can get wrong with it. Don't forget to check if your penal can handle a higher load though.

That's what's customarily done with heat pumps of all kinds.

Where I would be a little leery is due to the climate, Montana with lows of -30F.

On the NEEP.org website you can pick a heat pump and put in your zip code and heating load and it will tell you how many hours a year of backup heat you'll need. I would want to go through that exercise before making any equipment choices. You may find the heat pump runs relatively few hours a year.

Have you done the napkin math on the amount of hot water (stored capacity + recovery rate) you need to enjoy the illusion of "endless hot water"? 80gal of 150F water goes a long way with a mix-down valve. It's been more than enough for someone to fill our "slipper style" tub while someone else is showering. With a SanCO2, you can go arbitrarily large on storage and a single unit will deliver 17Gal of 150F water per hour at 40F incoming water temp. (SanCO2 units can be installed indoors: https://www.facebook.com/justin.gibbs.560/posts/pfbid0wU6LNkJpUR3vaaigZfUNYzbdTgzhS1cU32Wb6eg6Yb6k7Lvc8JPyFDxSuoGhGSy8l)

I've used tankless units for heat, the thing to watch is you might not get as much heat as you think out of the tankless. To get the rated BTUs, the unit needs very high delta T, the pipes through the unit are simply not big enough to flow much water at space heat delta T. Most to expect is around 30k to 40k, so make sure this is enough to handle your heat load. You'll also need a high head pump to move enough water something like a stainless Taco 009 ($$$).

I've also had issues with the IFC leaking overtime which will reduced the temperature of hot water the unit could deliver.

I would run your place through the calculator here. Pick a heat pump that is representative of your air to water ie:

https://ashp.neep.org/#!/product/34526/7/25000/95/7500/0///0

Click on the advanced sizing tool in the corner which will let you enter your exact design conditions and load and give you a nice graph to show how many hours of backup heat you'll actually need. Generally the runtime on backup heat is so low that any fancy setup is never worth it especially if your fuel source is propane. Put a simple large element in the buffer tank or use an electric boiler for backup and call it a day.

Veissman, Artic, Nordic, and SpacePak brands come to mind for a dual fuel system. Look at the TurboMAX reverse indirect tank with TXT as DHW tank. As mentioned above, the boiler will do the heavy lifting, where the A2WHP can maintain the tank temperature at the set point. Keep the DHW setpoint below 130F so you get full condensation with your boiler.

NG becomes more economical when COP falls below 3.0 depending on energy costs in your area. So do an economic balance point graph using your DHW usage graph. In Minnesota, Zone 6A, that number falls around 8F.

Once you have the balance point then look at the DHW demand in KWh for your household and compare to the output of the DHW tank at 120 - 130F.

Finally look at the materials used in the boiler and see if the manufacturer is using an alloy that works with hydrogen enhanced NG. That burns greener, but can shorten the life of equipment. The utilities are starting to run pilots of this blended fuel.

For controls, look at HBX and Tekmar. Belimo makes a good valve. For an ERV, the CERV2 or Zehnder integrate well with buffer tanks for pre conditioning in cold climates.

"NG becomes more economical when COP falls below 3.0 depending on energy costs in your area. So do an economic balance point graph using your DHW usage graph. In Minnesota, Zone 6A, that number falls around 8F."

This is exactly right, the starting point needs to be calculating the economic balance point and working from there.

That said, I'm not aware of any heat pump that delivers COP 3.0 at 8F. And even something like an Arctic which claims to deliver 3.0 at 14F has to have output water of 95F to get that, which isn't going to be adequate for DHW.

This is Montana, OP said he gets -30F every winter. Before even thinking about piping diagrams or control strategies I'd be looking at the balance point to see if a heat pump is going to make sense at all.

And the Manual-J (heat-loss) model is used to create balance point graph. Most things start with a good Manual-J, followed Hot Water Demand model.

The balance point is completely independent of the Manual J. It depends only on the cost of electricity, the cost of gas, and the COP curve of the heat pump.

Now, granted, you have to have an idea of what your heating load is like before selecting equipment, but I think you're overthinking this. Since there's no guarantee that a hybrid system is going to pencil out you really want to ballpark the heat loss and run the numbers before investing any more time in it.

If you have a tanked hot water system the demand for hot water is going to be pretty irrelevant.