Ventilating a Low-Sloped Roof Detail

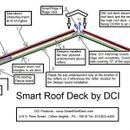

Hi there! Just some interesting facts to share with the readers of Green Building Advisor. DCI Products has many innovative products to share as well as manufacture and some yet to be created. This one article about the double roof system ventilating over the original roof deck seems to be identical to a patent that DCI Products owns since patenting it from 2013 through the patent US 8,973,310 issuing in 2015. After spending lots of time developing this concept and working with the patent office for two years, DCI Products president, Jack (John) Henderson received a US patent for this concept. The proprietary products used and manufactured by DCI for the Smart Roof Deck (SRD) System are specified for use with this System. The vapor permeability of the sub-deck and sub-underlayment being able to allow vapor transmission to pass through the building envelope at the roof level and the vapor flow through the air channels created by the sleepers and having the upper roof deck with shingles or other roofing materials above that envelope for protection is part of the claims in the patent. The sub-roof is also water-proof and used as a second barrier to the main roof deck above. Please visit the website at: http://www.SmartRoofDeck.com for additional information. Any questions regarding the SRD System, I would be happy to discuss. Thank you.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Jack,

Congratulations on your patent.

It appears that your claims are specific to shingled roofs. I guess that's because ventilation above the deck has been done for a long time on metal roofs?

I took a look at your web site, but didn't find what products you are selling. What products does one need to buy from you to build like this without, in your view, infringing this patent?

Thanks Charlie!

Receiving a US Patent is a very tough thing to do and costly. Once received it is the patent holder that needs to protect it. The description part Column 1 lines 20-30 of the patent states shingle roofs include metal shingles, sheet metal, roll roofing, cementitious, clay, asphalt, slate, etc. Check it out on the site. Metal roofs generally do not have a primary roof deck and a sub-roof deck. They have sleepers installed for support. The SRD patent has an air & moisture permeable underlayment on top of the sub-roof Wood/OSB/plywood decking that also sheds water (condensation) yet breathes. The Primary roof above has OSB/plywood with an option for a radiant barrier attached to the lower side of the primary deck for radiant barrier protection (Florida, Texas, etc.) and superior energy efficiency. DCI sells plans, specs, intake ventilation, ridge ventilation, permeable sub-roof underlayment and permission to use the patent on that particular project project. Hope this helps clarify your questions. Thanks!

So you are specifically claiming anything with two decking layers, and with a vapor permeable membrane on the lower layer. And the use of the upper decking layer is how you distinguish from prior art using metal roofs.

I can't off hand put my finger on a specific prior example that combines those features, but it seems pretty likely that someone motivated could find one. And the constellation of similar designs, and books explaining the concepts, might make an obviousness argument hard to defend against.

In addition, finding cases where people have done this to go after them for infringement will be really hard. It is more feasible if a large company is making thousands a year. It can then be worthwhile to go after them.

So it might be easier to defend a patent on the special components, if there is anything special about them.

Charlie, you are exactly right. Thank you for mentioning that. We use our Fascia Strip Vents, FasciaVent as intake or the SmartVent when specifying the SRD, as well as the DCI SmartRidge II and/or SmartRidge I for exhaust at the ridge. I initially was only stating the patent on the roof system because the DCI vents were not shown at the fascia in the detail. A couple other items to point out by other members is that the insulation is stated in claim 1-a as it states a building as the first claim and the building includes insulation that does not block ventilation (patent column 5- line 19 to 22) and floors, ceilings, etc. As long as the insulation allows water vapor to permeate, it is covered in the claims. Also and a much bigger benefit is the '2 x 4 sleeper's are left 14" short in the valleys, hips, skylights, dormers and chimneys so air flow can move under the primary deck and out the SmartRidge vent. This is not possible using standard rafter framing. This diagram is shown on the web site. Thank you for your professional view points.

I don't know whether you are missing my point deliberately, or whether you really didn't understand it, but the description of insulation in column 5 line 19-22 does not distinguish the invention from the the BSI diagram linked in comment #24. The insulation in the BSI diagram does not block the ventilation (between the two roof deck layers). I don't see anything in the claims or the specification that limits the invention to vapor permeable insulation. (I trust you understand that ventilation is different from vapor permeability.)

If your patent and the claims do not distinguish from the prior art, it is not valid.

I see "above the structural sheathing roof venting with shingles" drawn here, years before the claimed invention date:

https://www.buildingscience.com/documents/insights/bsi-046-dam-ice-dam

I'm curious, why isn't this listed as "prior art"? Does anyone have other, prior to 2013 examples?

> This one article

What article?

> low slope

Where does this come from? The patent shows a slope that isn't low.

Somewhat related: Is above the sheathing venting of a fiber filled cathedral ceiling code compliant? IRC 806 says the rafter space itself needs ventilation - not some separate space above it.

Hi Jon,

I am a true believer in Joe Lstiburek and have spoken many times to him in person at trade shows. The differences in the concepts that DCI promotes, is total air & moisture permeation from the interior of the building (exiting) as well as a total seal of the building envelope. Joe is describing a non-breathable (air & moisture) configuration of foam insulating with tar paper between a vented nail base shingled roof. So the ventilation is strictly for the shingle warranty and heat build-up of the shingles. No air & moisture is being transmitted through that roof detail (traps the stale air and moisture below the foam panels. The codes are vague on sealed building envelopes, but that is the direction the Energy Codes must go. DCI is ahead of the curve. Please review all the benefits on our web at http://www.SmartRoofDeck.com . The slope of the roof in the patent is addressed (Column 1 lines 24-44) as "pitched roof" meaning any pitch. In addition, the system allows for the escape of water vapor from the inside of the building through the assembly (Column 1 lines 15-20). Thank you for the great questions!

I believe this is the image Jon is referring to: https://www.buildingscience.com/sites/default/files/migrate/jpg/BSI046_Figure_08_web.jpg. Perhaps I missed it but I can't find in your patent a description of what the cavity insulation or interior finishes or membranes include; in other words, it's not part of your patent, despite any intention. The Lstiburek roof shows the same detail as you from the rafters outward. Roofing membranes are available that are vapor-open or vapor-closed, and waterproof (essentially) or water resistant. Your vent location between the fascia and sub-fascia is even the same as they show.

I first saw Dr. Lstiburek present this roof system around 2010 or 2011, and the article date is 2011. I don't think anyone is arguing that it's not a good system; it is. That's why many of us have used it, or something close enough that it would be in violation of your patent language.

Your patent claims are clearly limited to the sub-deck and membrane on the sub-deck being vapor permeable. Neither the claims nor the specification limit the type of insulation below there. So the documented prior art is included by the claims. I'm afraid that means the claims are not valid.

Clearly you have an interest in energy efficient and resilient building. I'm sorry that your attempt to build a patent revenue based business isn't working out. I hope you can recover from that mistake and join forces with the green building community to help advance the field.

+1 on what Michael and Charlie said.

> No air & moisture is being transmitted through that roof detail

This isn't true - even rigid foam has some vapor permeability and has air leaks at the edges. Or using your logic, if there is a vapor/air barrier on the interior side (blocking air & moisture), then your patent doesn't apply?

I'm not an attorney, but I'd be careful of:

"A finding of "fraud," "inequitable conduct," or violation of duty of disclosure with respect to any claim in an application or patent, renders all the claims thereof unpatentable or invalid."

'... the jury awarded TransWeb $26 million for antitrust violations based upon 3M’s attempts to maintain its monopoly by asserting a fraudulently obtained patent."

" applicants have a duty to file claims that do not exceed their invention. And though it likely comes as a surprise to much of the patent bar, that duty is enforced by criminal sanctions. Simply put, willful overclaiming is criminal; it is a felony. "

Someone better inform the thousands of builders that have been using this detail for decades that they're infringing.

Thanks Kyle,

Unfortunately, it is our understanding that the builders are not using this method. Most have long term decay problems using foam based nail bases without a mechanical system to protect the interior environment. When trapping moisture within the building envelope, it requires a mechanical vent system to recirculate the interior air at key high spot returns near the ceilings (peaks in cathedrals) which most homes do not have. The key elements of the DCI patent is to allow all material below the roof top air channel to allow water vapor and air permeability to travel through and have a waterproof, permeable subunderlayment to protect any moisture from re-entering the building envelop while achieving air flow ventilation. Without this process and material interaction, trapped moisture within the vented nailbase material that does not permeate moisture or below the vented nailbase roof deck will possibly create an environment of mold, rot and decay because there is no method for drying out or diverting this from happening below the foam panels. All DCI elements that have been patented are required and they work harmoniously together. Open foam panels (part of a nailbase panel) do not permeate moisture enough to be effective. Thanks!

Jack Henderson,

This attempt at bullying GBA readers (and GBA) is the most flagrant example of corporate stupidity I've seen in years. ("Using competitive products without permission from DCI is called 'Patent Infringement' " !)

Jack, you may think that you invented above-the-sheathing vent channels in 2015 -- and your half-educated corporate lawyers might have convinced some officials at the patent office of your claim, in spite of the fact that patent attorneys never visit job sites -- but you didn't invent above-the-sheathing vent channels.

The irony, of course, is that GBA is your potential ally. If you bothered to perform even a cursory search of our web site (instead of posting bullying threats), you would easily discover that we've been promoting your products for years. Instead of recognizing GBA as your ally, you've managed, with this single post, to alienate thousands of potential customers, every single one of whom is rolling their eyes and vowing to never buy anything from your company again.

Well Martin, thank you for bringing this to my attention and whip lashing me at the same time. I have not and never will state what you have claimed in your comment above regarding first to invent air channels as is stated in the patent. Try defending a patent that has cost $75K-100K plus and see it vanish. This DCI patent does not work with any foam panels since foam is not breathable, although open cell claims a slight permeance. This patent was developed to help the building industry cope with all the failures that are experienced. Please read the benefits. Please do not degrade one for fulfilling his purpose in life, developing products that help the home building community. What you have just stated is beyond disrespect. DCI holds the original patent for SmartVent under-shingle intake and exhaust vent which is probably what you are referring to above, and has become a dependable tool for builders, contractors, and architects throughout USA and Canada, in all climate zones. If you have specific areas you want to discuss, please call me at 800-622-4455. I would be more than happy to discuss whatever you are disheartened about. I mean no harm to you or the GBA community and we only want what is best for the construction industry. One knowing that a roof system has a patent and really works as stated may be a blessing to understand. I do not understand you being irrate at me because I am stating facts and defending what the government states is ours and we must defend it to secure the benefits. I hope my answers thus far help in understanding that it is the elements and roof protections that I have patented to make this vented roof completely energy efficient and to stop growing insurance claims for roof failures. Thank you.

I hadn't checked out the main DCI website https://dciproducts.com, or refreshed my memory about what their products are. Those are great products that I've used myself, recommended, and seen recommended here many times! Such a shame to take that good, well deserved, hard earned reputation and trash it by changing business models to patent trolling!

Haha, this is a "patently ridiculous" idea. Please share your patent language so we can either laugh at how general it is or how specific it is. Either way, I will continue over-venting roofs when it makes sense, thank you.

Hi Michael,

Please see my reply to Martin. I am sorry that some people think a highly energy efficient roof system that has a secondary protective roof barrier and one that completely seals the building envelope from the wrath of the Mother Nature is a "HaHa" moment and/or "ridiculous". Our concern in developing this system was, what happens when condensation forms when weather conditions change. This may be from nail shanks, foil foam, moist air, etc. Does it seep through the foam sheets at the seams, or get trapped below the non-porous foam allowing the old plywood deck to be damp and wet? What happens to the moisture trapped in the attic? Seemed that there were opportunities and methods to create a better ventilated roof system. We were also concerned about the structural integrity of screwing the panel systems over the old plywood deck with only the screws in the plywood holding the new roof system in place. So, DCI saw the opportunity to develop a roof system that corrects every aspect of our concerns and called it Smart Roof Deck. We looked at all problems from gutter back-ups to shingles leaking, to energy efficiency, to fire prevention, to preventing attic frozen pipes, etc. We enjoy having interactions regarding good building practices and enjoy GBA and all their efforts. I apologize for using a word that has raised some hairs a bit and will refrain from doing so going forward. Thanks GBA for allowing these discussions and bringing us all to the table. Have a safe Labor Day Weekend to all! Patent info is on http://www.SmartRoofDeck.com

Jack, thank you for pointing me in the right direction to your patent language: http://smartroofdeck.com/wp-content/uploads/2019/02/US8973310.pdf. I don't think that the system is ridiculous; quite the opposite--it's very close to the approach that I and other high-performance builders and designers all over North America use regularly.

I have read quite a few patents and it's often clear that patent attorneys and the US Patent Office do not understand common construction practices, so many of the ones I've read are not really enforceable. I'm not an attorney but yours reads to me as mostly explaining basic building science concepts, with descriptions of the components that are pretty general, to the point that they are simply standard construction techniques. I suggest you look into "Sarking Membrane" systems common among high-performance builders in the US and common in Europe. While they don't include the sub-sheathing, your description of sub-sheathing would include a typical Sarking Membrane system. Similar systems have been used in the US since well before your 2015 patent date.

Jack,

Back in 2011, four years before you received your patent, I wrote "How to Build an Insulated Cathedral Ceiling." In that article, I wrote, "If you prefer, you can locate your ventilation channels on top of the roof sheathing rather than under the roof sheathing. If you decide to do this, make sure that any roofing underlayment that you install above the roof sheathing is vapor-permeable — for example, #15 asphalt felt, VaproShield SlopeShield, or Solitex Mento — and that your local building department accepts this approach to roof venting. If you install ventilation channels on top of a vapor-impermeable synthetic roofing underlayment, the flowing air won’t be able to help dry out the roof sheathing. ... You can create 1 1/2-inch-high ventilation channels above the roof sheathing with 2x4s installed on the flat, with the 2x4s located above the rafters, 16 inches or 24 inches on center."

I wrote much more on the topic. I offered my advice to all readers and invited anyone who wanted to copy these details. I didn't apply for a patent, because these ideas were already out there. They were decades old.

Your patented system, shown in the image below, never deserved a patent, because you didn't invent it.

Martin, with all due respect, the details of what you have sent do not distinguish between the DCI patent and the article was updated in 2018 for "vapor diffusion ports". (??) At best there is a sarking membrane in one detail, stretched across the rafters. Most sarking membranes are non-permeable yet some are moisture permeable. In addition there can be no foam based materials at all in the elements of the roof configuration in the DCI Patent. The DCI patent states that all insulation products below the subdeck are required to be moisture permeable and that there be a sub-roof deck above the insulation that is also moisture permeable yet is equipped to shed water above the sub-deck without the water re-entering the building envelope and safely shedding out the eave area. This can be through permeable underlayment or moisture permeable Zip systems with seams taped and sealed.

Furthermore, the requirement is to have vent channels between an upper roof deck and the water resistant sub-roof deck created by adding structural ‘sleepers’ which are installed allowing ventilation channels to properly vent skylights, chimneys, hips, valleys, etc. Sure, many roofs have foam insulated panels with vent channels (chutes) above but the DCI patent expressly states the insulation, sub-roof and the water resistant sub-roof upper surface all be moisture permeable with air channels above yet below the primary roof deck. The primary roof deck can be virtually any slope and any roofing material.

The on-site manufactured double roof system allows for all these key elements to happen. Vented nail base products cannot be made waterproof on the lowest panel below the upper shingle base. That would be impossible to accomplish.

I have added a few notes below that were highlighted in the article you referenced with updates made in 2018 (many years after our application and patent issued).

GBA Quotes: The Articles are UPDATED on August 31, 2018 with information on.... vapor diffusion ports. (??)

Martin’s Response to John W.

John,

Your plan will work fine, as long as the layer of... rigid foam on top of your roof sheathing... has an R-value of at least R-20. If you are using XPS, you need at least 4 inches of foam. If you are using polyisocyanurate, you need at least 3 inches of foam.

You are in climate zone 5. I explained the minimum R-values for the approach you are taking in one of the paragraphs above, in which I wrote, "According to ... the 2009 IRC, “rigid board or sheet insulation shall be installed directly above the structural roof sheathing as specified in Table R806.4 for condensation control.”

DCI Response: The detail referenced in the article has a ‘Sarking’ membrane above the rafters (no sub-roof deck) and a vapor and air reducer on the.... heated side of the rafters...., fully detailed. (This was published in the article you have just referenced). These details are not part of the DCI Patent. This detail does not reflect a walkable, supportive, moisture permeable sub-roof deck nor the fact that moisture must permeate through the insulation and into the vented air channel. These are critical areas of the patent and not a moot point. Although, it is possible these were added after 2018, when DCI was actively in it's third year of promoting the new energy efficient roof system to builders, architects, engineers and contractors, but as stated 'vapor diffusion' information was added.

In summary, the USPTO office, as well as our professional patent attorneys, did a thorough investigation of all the claimed elements worldwide and found no prior art. I only want the readers to understand the effort we have gone through and the positive results which have been achieved in doing our due diligence. It was never my intention to discredit anyone but when other products outside of DCI are being specified and used to create another person’s invention, something must be said. It is the American way. Please forgive me if I have crossed the line but the truth be told. We have invested millions upon millions of dollars to the Roofing Industry to try and make it better and are only bringing inequities to the public's attention. God Bless Everyone and Godspeed, Jack Henderson, President, DCI Products

Jack,

You wrote this about my cathedral ceiling article: "At best there is a sarking membrane in one detail, stretched across the rafters." To the contrary: in the paragraph I quoted in Comment #12, I wrote, "you can locate your ventilation channels on top of the roof sheathing rather than under the roof sheathing." The phrase "roof sheathing" refers to products like plywood.

Your deliberate confusion of the vapor diffusion port approach with above-sheathing ventilation channels is nothing but obfuscation. Why did you put double question marks after the phrase "vapor diffusion ports"? To my mind, those double question marks certainly imply that you are ignorant of this code-approved option for builders in Climate Zones 1, 2, and 3. Note that the vapor diffusion port option does not include above-sheathing ventilation channels.

My quoted paragraph (in Comment #12) concerns above-sheathing ventilation channels -- an approach you did not invent. Dragging in another topic entirely -- vapor diffusion ports -- is, as I say, nothing but obfuscation.

Martin,

I will end the discussion with you since the modifications made in 2018 are regarding items associated with our 'advertised' roofing system and vapor diffusion. The prior drawings, descriptions and elements do not add up to what you are stating. I am not here to belittle you, me or anyone else. I am only stating the facts. Below are the referenced roof details you have sent me and not one has our elements nor the elements you are claiming.

This BSC article is helpful

http://www.buildingscience.com/documents/published-articles/pa-crash-course-in-roof-venting

same article at Fine Homebuilding

http://www.finehomebuilding.com/how-to/articles/a-crash-course-in-roof-venting.aspx?langtype=1033

here is a good video and discussion about roof ventilation

https://www.greenbuildingadvisor.com/blogs/dept/building-science/lstiburek-s-rules-venting-roofs

I will address those professionals that treat my responses as equally professional and will not respond to sarcasm. It is with regret that I am disappointed in many of the responses and have tried to be honest and forthcoming to all.

Jack,

You wrote, "Below are the referenced roof details you have sent me." But I never sent you those references. Instead, I posted (in Comment #12) a quote from my 2011 article, "How to Build an Insulated Cathedral Ceiling," demonstrating that all of the basic elements of the roof assembly you patented were described in my article four years before you received your patent. The relevant information can be found directly under the subheading, "Creating vent channels above the roof sheathing."

It is certainly ironic that you are gracious enough to include a link with the advice to me that "here is a good video and discussion about roof ventilation." The irony, of course, is that I was editor of GBA when that video was published on our site. But thanks for reminding me of Lstiburek's advice.

Jack, since you are promoting above sheathing ventilation (ASV), do you have specific (and unbiased) data showing its measured performance relative to vent below sheathing designs? For example, a cathedral roof, good interior side air sealing, with the vent:

immediately below sheathing, no vent baffle

immediately below sheathing, non air-tight baffle

immediately below sheathing, air-tight, high perm baffle

immediately below sheathing, air-tight, low perm baffle

above airtight OSB sheathing and vapor permeable underlayment (ASV)

I expect that the first outperforms the last in terms of driest sheathing. And that the 4th (a cold side vapor barrier) suffers from condensation below the baffle.

Jon,

DCI's goal to this SRD roof system was to create a 100% sealed building envelope and to vent the attic space moisture and air through permeability. Our goal was to indirectly create an energy efficient conditioned attic space, where the heat is dissipated out the configuration slowly but effectively with the moisture. There are no requirements to seal the cracks between the attic and living area as long as the building envelope is 100% continuous. We have test results on our SRD system to prove that the humidity levels are stable and the temperature levels are as anticipated but not by the comparisons that you have mentioned. This is because our goals were not to allow outside weather to enter through the building envelope which would bring in fluctuating temperatures and moisture levels of various readings. We have a 100% controlled system by incorporating the existing levels of comfort according to each individual homeowner. What we are working on is the recording of the energy efficiency savings of a controlled attic environment verses a fully vented attic. By using baffles within the envelope, external weather is being brought in which lowers the energy efficiency. One thing to remember, when dealing with attic soffit to ridge ventilation, is the primary roof system above basically has no air or moisture permeability because metal or asphalt shingles are nailed above and most underlayment that breathe will not breathe when asphalt shingles are applied directly to the 'breathable' underlayment.

While I appreciate it's probably important to address Mr. Harrison's claims to have an exclusive right to above sheathing vented roofs, I'm still a bit puzzled as to why this is being taken so seriously, and not just dismissed as a joke.

A bunch of rubes in matching company shirts, with ridiculous corporate titles, who describe themselves as roofing gurus, claim to have a patent of something that has been commonly done for decades. It's not worth spending time on.

Malcolm, I would love to meet Mr. Harrison, I think we have a lot in common. It appears you do not want to spend time on dealing with Energy Efficiency (EE) which is becoming the #1 topic in building construction. Sorry to say, but EE is very serious for our future and a great opportunity for Green Building to put these articles at the forefront. It is not a good feeling that there is such ridicule on this thread. I really thought GBA members were trying to fulfill a mission of Green technology and were open to honest discussions. You seem to want to trash Mr. Harrison and ridicule his hard work. Please explain your mission for even being a part of this thread. Thank you sir.

Henderson, Harrison, whatever your name is: Stop wasting everyone's time here and go do something productive. You are just digging yourself a deeper hole with each post. The more people that read this the worst your reputation becomes.

I'm imagining a fence, where each post is set deeper and deeper until the top of the fence is just a foot off the ground.

Lots I could say about the patent, but it won't accomplish anything. So I'll continue to try to extract useful information.

An ASV attic or cathedral roof that is well air sealed sounds a lot like a very large but low perm diffusion port. Joe L showed that typical diffusion ports didn't work well enough in cold climates. So I'm interested in seeing the data showing that sealed, ASV attics and cathedral roofs work.

If diffusion alone is enough to keep a sealed but unconditioned attic dry, why do I need ASV? Can't the moisture just permeate through high perm gable ends?

In cold climates, a roof assembly is driest if moisture in the assembly doesn't have to diffuse through anything before it leaves the assembly. Ie, air can flow from the air sealed interior side all the way to outdoors. A vented attic does this - and is known to work well in cold climates.

Jon,

Your comments here on GBA are invariably evidence-based, so I can understand the temptation to try and extract some useful information from this discussion, but so far I see no reason to believe Mr, Henderson knows anything beyond what he had learned from the sources you are already familiar with.

Good point, I give up on getting data.

IMO, the industry is in a bad state if it's not clear what venting is code compliant and the question in #13 isn't well researched.

The IRC says "...enclosed rafter spaces formed where ceilings are applied directly to the underside of roof rafters shall have cross ventilation for each separate space". Add an air-tight baffle and you have created a separate space, leaving the lower rafter space (with the insulation) unvented. Similar for ASV - the rafter space itself isn't cross ventilated.

Jon, thanks for your interest and good questions. The gable vents are sealed off in a Smart Roof Deck (SRD) system and insulated with all materials breathable. The side walls are also insulated as well as the ceiling to the upper rooms in the house. The degree of energy savings depends on the amount of insulation being installed. A typical vented attic is very inefficient energy wise. We are addressing the energy efficiency marketplace by using the SRD system. To maintain a conditioned attic space with using the heat loss from the house is the way the attic is conditioned using the SRD system. The ASV allows moisture to expel out of the sealed envelope and helps control the shingle temperatures as well as retains the shingle warranties. We are continuing our research on energy efficiency using the SRD system by monitoring insulation R factors along with U values, recording moisture levels and recording energy use at different energy use cycles. It is a long process but we are committed and serious about what we are bringing to the roofing marketplace. One might say we are passionate about it. Thank you.

If, by "typical vented attic", you means an attic with 3 inches of degraded insulation on the floor and lots of unsealed penetrations, you are absolutely right. But a vented attic built by a high performance builder can be very efficient. It will have R60 to R80 insulation, a tightly sealed ceiling plane, and raised heel trusses. To beat that, you'd need R100 or more at the roof. You could do that, but to claim that this approach has inherently better energy performance is absurd.

Your claim to be the inventor of this approach is pretty dubious. Adding unsupportable claims about energy efficiency is not helping your credibility.

This is the funniest thread I have read on GBA!

Luke, I do not see the comedy in this thread. Could you please explain your comments as being the funniest thread on GBA, after you read this link: https://newbuildings.org/code_policy/2021-iecc-base-codes/

Thanks and have a nice day.