When encapsulating, should insulation cover a rafter bay of lower roof vertically?

I’m encapsulating a small attic space (8.5 linear feet) by air-sealing the exterior faces and then installing several layers of polyiso, in CZ-2. That space butts up to a lower roof. Should my foamboard run from the ridge down to the roof sheathing, or should it go all the way down to the ceiling, in front of the rafter bays?

I’m covering the rafter bay with OSB to have a clean wall to work with, I just don’t know how far down to run the polyiso. Running it all the way down to the ceiling seems like more insulating power, but maybe insulating something that’s not an exterior face is contraindicated.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I assume I should cover it, but I'm often surprised by details that I read about on GBA, so I'm just double-checking.

Michael,

I'm having a hard time understanding the geometry of what you're describing, even with the photos. A sketch might help. It might also help you visualize how things are coming together. You may also need to include details about venting (or lack thereof).

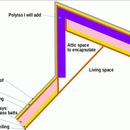

Okay, here's a side view of the stackup. Yes, the two roofs don't meet normally to form a triangle, one roof is lower than the other. I will for-sure install polyiso on that left wall where shown, because that's an exterior roof/wall, and the whole point is to insulate the inside from the outside. The question is, do I run the polyiso down all the way to the wood ceiling? That would also insulate the rafter bays of the lower roof, which is neither truly inside nor truly outside, but more outside from a thermal point of view. So I'm inclined to think that I do run the polyiso all the way down to the wood ceiling, but maybe there's something I'm missing, hence my post.

The polyiso will automatically cover most of the rafter bay on the right, but I could extend it so it covers the whole thing.

The elements in the drawing are mostly to scale, but the house itself is shown much smaller than actual. The attic space I'm encapsulating is a lot larger than shown; the picture suggests that after encapsulating there won't be much air space left, but in fact there will be.

Interesting detail.

I don't really see any reason you can't extend the iso down, at least halfway, so that you don't have a thermal weak spot at the intersection (note on your current drawing the lack on insulation where the purple line meets the pink). I guess you could be getting a small amount of drying of the fiberglass bays out that top though seeing as it's sandwiched by EPS on both sides?

What climate zone are you in? The unvented EPS foam sandwich doesn't seem like a totally safe assembly. Have you noticed any issues with it?

CZ-2, I usually note that in the post, forgot to this time, sorry.

There's not much EPS. As you can see from the photo, it's like only 1/2" to 1" on top. No problems that I know of, but it's not easy to check: With a cathedral ceiling, I can't easily check the underside of the sheathing.

I would extend the polyiso all the way down to the wood ceiling, which will make air sealing easier. It's difficult to air seal the end of a fiberglass batt without some kind of rigid air barrier material to cover the end of the batt.

You need more exterior side EPS to make this a safe assembly, unless you have very little R value in those batts. If you don't have the right ratio of exterior to interior R value, you run the risk of moisture issues in the batts. In CZ2, you need a lot less exterior insulation compared to what I wold need in my CZ5, but you still need somewhere around 20% (in my CZ, 50% is recommended).

Is that interior side EPS taped and sealed as an air barrier? I'm assuming by "wood ceiling", you probably mean some type of tongue and groove ceiling material, which isn't an air barrier. You really need that interior side air barrier.

Bill

It's not difficult to air seal the end of the rafter with the fiberglass, because I already covered it with OSB (as shown in the second picture). I edited my diagram to show the OSB that I added over both rafter bays.

The assembly has held up for about 40 years so I'm not particularly considered about moisture in the batts, unless running the polyiso all the way down to the wood ceiling would significantly add to the moisture risk. Would it? That was the point of my post, to see if there's a reason I shouldn't run the polyiso all the way down to the wood ceiling.

FWIW, in the 1st photo you can see some boards between the upper EPS and the roof sheathing. They're made out of some kind of cardboard-like material, I can break it easily with my hand. They seem to be there to provide some airflow.

I have no idea whether the interior EPS above the wood ceiling was taped and sealed, since the assembly was installed 40-odd years ago by some unknown person, but I doubt it was taped and sealed, given all the various construction mistakes I found in the house, coupled with how little most people knew about building science circa 1980. GBA was not around then.

Yes, you need to run the polyiso down as Michael says; right now you have a huge thermal bridge. I'd probably run it all the way to the ceiling. The second issue is that the R values of the vertical wall look to be less than anywhere else. Perhaps you could add another layer of polyiso there.

My plan is six 1" layers (6" total) on both the wall and the underside of the roof. That's R-39.3, current energy code is R-42, close enough for me.