Waterproofing between concrete porch & house framing

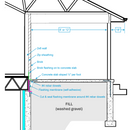

I have a house under construction and need some help with waterproofing where the concrete porch slab meets the house framing. See attached diagram and photo.

I don’t expect much bulk water to get between the porch slab and the house, because the porches are covered and the brick veneer will be flashed on to the top of the porch slabs. My main concerns are vapor drive through the concrete slab and condensation between the slab and the house.

A weak point in the current waterproofing plan is the #4 rebar dowel penetrations through the flashing membrane (these dowels tie the foundation walls to the porch slab). The membrane will need to be cut around these penetrations and detailed with sealant.

Locally, H&B Textroflash is commonly used as the self-adhesive flashing membrane between concrete slabs and house framing. An additional protection course on top of the flashing is not typically used.

I have a few options at this point, in order of increasing cost:

1) Proceed with the current plan (self-adhesive flashing membrane), and maybe add a protection course (e.g., 1/4″ drain mat) on top of the flashing membrane, to keep the membrane from being punctured during construction of the porch slabs.

2) Cut off the #4 rebar dowels, then proceed with the current plan, and then drill and epoxy the rebar dowels back in place, through the flashing membrane after it’s been applied. This might provide a better seal around the dowels.

3) Add a waterproofing admixture to the porch slab concrete, but otherwise proceed with the current plan.

4) Cut a brick ledge into wall for the concrete porch to sit on, then proceed with the current plan, then drill & epoxy new #4 rebar dowels. The brick ledge would give a place for a small amount of water to go without being in contact with the framing (There was supposed to be a brick ledge originally, but it was omitted during construction)

5) Turn the porch slabs into “roofs” by adding a waterproofing membrane on top, followed by a topping layer of tile or pavers, e.g., the Tiledek system by Duradek (and also do the current waterproofing plan).

I’m leaning toward #1 or #2. Getting #3 done might not be possible with our concrete supplier. #4 has the potential for structural problems (e.g., if they overcut the brick ledge and weaken the wall below the sill plate). #5 might be the best, but will be expensive and I would rather have a brushed concrete surface on the porch.

Any other ideas?

Hindsight being 20/20, I would have gone with a different approach to tying the porch slabs to the house. For example, we could have raised the foundation walls and dropped the floor trusses behind them on a ledger or framed basement wall. Oh well. This is what I have, and house framing starts next week. Any help or ideas would be appreciated.

p.s. This is climate zone 4a. Frost depth is 24″. All foundation walls extend below frost depth.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Yes, this is a situation I usually try to avoid. If I ever have to place concrete next to wood like in your situation I make sure there is a good liquid applies or continuous peel and stick over the wood and then a heavy gauge metal sheet separating them. In your case I would have it bent in a z fashion so that it would drain to the outside of your foundation wall.

I don't think your inclination to use new epoxied dowels is bad. You could install these after the sheet metal and slightly overfill the hole with set 3g epoxy so that is oozes out slightly and seals and bonds the metal.

At your metal joints I would either solder, butyl tape, or zip tape. I have found Zip tape to have incredible sticking performance to clean metal. Idk If you need a dimple mat, but a thin layer of rockwool may be a good idea as it acts as a drainage plane and insulation. Also, make sure your insulation at your rim is very tight on the exterior as it will constantly be a condensing surface with nowhere to dry.

Edit: Obviously make sure your engineer is good with the epoxied dowel

We have spray on water proofing and dimple mat on the exterior of the concrete foundation walls. Metal flashing is an interesting idea, I'll check to see if we can get someone to form stainless flashing.

As you mentioned, insulation and condensation around the rim board is an area of concern. We're trying to avoid spray foam (chemical sensitivity), so the original plan was to pack Rockwool in the rim board area, and then inspect it during the first year to see how it does. If it promotes condensation, we'll take it out and try something else.

Instead of a vapor impermeable waterproof membrane between the house and porch slab, I wonder if something like SlopeShield Plus or PanelShield SA would be okay? At least the rim board might have the chance of drying to the outside?

IGR123,

My retrofit suggestion would be to mimic what you suggest at the end of your post by pouring something like my attachment - which can either be structurally connected to your slab or not, and has a direct concrete to concrete connection (no membrane) between it and the stem-wall below.

Then your only concern is moisture that may move through that thin portion of the stem-wall by capillary action or diffusion - and that's easily dealt with by running a peel & stick membrane down the inside and under the sill-plate.

You don't want a permeable membrane there as there will be no drying to the exterior below grade, as the moisture drive will be inward. Ideally you would have a layer of foam between the trusses and the concrete, but there may not be room.

Malcom, thank you for the suggestion. It looks like this new mini-stem wall would need to be poured before the floor is framed? So that a membrane could be attached to the inside of it, and then under the sill plate.

I think we are stuck framing the floor and wall first, because we have to attach top & bottom ribbon boards to the trusses (they are already in production at the truss plant), and we also need to attach Simpson FWANZ foundation anchors to bottom ribbon to resist backfill pressure (they're nailed on from the outside).

Igr123,

No it can be poured after much like the down turned slab. Really it is just a slightly different shaped variation on the down-turned slab edge and could be poured as one piece just like the existing design, or separated by a thin filler. The only significant difference is it extends lightly higher. Either way it could be poured at he same time as the slab, and the foundation anchors can be nailed right through.

The membrane can be two pieces. One installed as a capillary break under the sill place and up its exterior side, the other attached to the outside of the ribbon board.

I see now. Yes, the raised slab edge under the brick would help keep water out.

Is the other aspect having a direct concrete-to-concrete connection where the new concrete meets the existing foundation wall?

I had assumed that running the membrane down the sheathed floor trusses and on top of the foundation wall (before pouring the slab) would help reduce moisture transfer. But maybe it's not necessary? Or maybe a direct concrete-to-concrete connection is better for some reason?

Igr123,

I don't think it matters much whether there is a membrane between the two or not. If there is a raised curb on the slab at the house, and any water that gets into the gap between the WRB and brick is diverted to the outside there, you are really only worried about moisture from the fill under the slab migrating through the stem-wall.

Since the fill under the porch is higher than the surrounding grade, realistically how much moisture will there be? I wouldn't worry about that joint. Providing a membrane to separate the wood framing from the concrete is the important thing.

My section is probably a bit misleading. The bottom part will look more like your original one with a sloped downturn. It's the addition of the curb on the top that matters.

The raised curb is a great idea. I'll see if we can incorporate it into the slab.

I think you're right that, realistically, there shouldn't be much moisture in the porch slabs. The porch is covered, the fill rock is 12"+ above the surrounding grade, and the footing drains go to daylight (walkout basement).

In that case, my concern about condensation possibly causing standing water at the sill plate level (see attached diagram) might not be much of an issue. I was thinking this condensation could occur in the summer when the A/C is on, keeping the house cold. But with rim board insulation and a slab that doesn't have much moisture, I can see how it would be unlikely to have this much condensation. Perhaps I shouldn't be so worried about the vertical rebar penetrations.

lgr123,

I wouldn't be worried about the rebar at all. The membrane becomes the first condensing surface, but If there is no void, there is no where for water to pool. The down-turned slab can stay as wet as it wants without causing any problems.

The only part that I'm unsure of it the best way to insulate the ribbon boards, and what type of air-barrier to use on them.

If you have any ideas for insulating the ribbon board area, let me know. We have been stuck on this issue for a while.

I know we need to prevent indoor air from migrating to the rim area and condensing on the sheathing. One approach is to use insulation that stops air movement, e.g., spray foam, which we'd like to avoid.

But what draws the air to the rim board in the first place? Is it natural convection? Or does it occur when the home has positive air pressure relative to the outdoors, so air is pushed out the rim board area through cracks? If so, could air sealing the rim area fix this issue and make it possible to use Rockwool or some other insulation that doesn't completely block air?

igr123,

It's not so much that the air is drawn to the rim-joist, as that in the absence of an air-barrier of some kind the same moist indoor air is at the rim-joist as it is everywhere else inside the house - and that rim-joist is cold enough that it takes on water by adsorbtion.

The usual (and safest) practice is to use insulation like spray foam or foam board as a combined air and vapour barrier. If you want to use air-permeable insulation like rockwool you need a sheet good (either poly or a variable perm membrane) on the inside of it carefully sealed at each truss bay.

The complication in your case is that there is no drying to the outside, so the assembly isn't very forgiving of small leaks. However, my own feeling is that installed diligently, any of the options I've suggested will be fine.

Malcolm,

Since the assembly can't dry to the outside due to the waterproof membrane, what do you think about adding 1" of Rockwool Comfortboard 80 between the porch slab and the waterproof membrane?

It would be R-4.2, which in our climate zone 4a should probably be enough to keep the sheathing warm and dry, and prevent condensation if indoor air gets to the rim board and sheathing? That is, as long as we don't add too much interior insulation. Maybe just 2" to 3" of Rockwool or similar on the inside.

Our builder thinks we probably have enough room to add 1" of insulation between the sheathing and porch slab. There is a 4" ledge for the porch slab, so this would leave 3" of bearing for the slab.

I've attached a couple of diagrams, one with a concrete curb, and one with a "brick" curb.

p.s. would we need to put a thin layer of plastic, e.g. 6 mil poly, on the outside of the Rockwool before pouring the slab? To prevent the concrete from filling the pores in the Rockwool insulation.

lrg123,

If you have the room for it, an inch of either comfortboard or foam would transform the area from something you might want to keep an eye on to something you can completely forget about.

Good point - a strip of house-wrap or poly will help maintain the insulating qualities of the rockwool.

I'm on the fence about adding the 1" of external insulation, because it reduces the bearing area for the concrete porch slabs.

I've been trying to figure out how to put all the insulation on the inside of the rim board, yet still allow the rim board to dry to the interior, since it can't dry to the exterior due to the low perm waterproofing peel & stick flashing.

It seems like if I add 1" or 2" of XPS inside the rim board (caulked and sealed), and then 3.5" or 5.5" of Rockwool, this might prevent condensation of indoor air in the rim board area while also allowing the sill plate to dry to the inside if necessary (because the sill plate won't be completely covered with foam). See attached drawing.

One potential flaw is that we're using Mitek LJQ35-TZ brackets on each I-joist, to handle lateral soil pressure on the basement walls.. They could act as a small thermal bridge, although they're sandwiched between the rim board and I-joist, so they shouldn't be that cold even in the coldest months of winter.

(also note that I've switched to I-joists from floor trusses, because the floor trusses didn't work out)