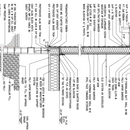

Wall section schematic help

I have a wall section scheme from an architect that has multiple vapor retarders and i’d like to value engineer it for energy and $savings- I think there is a lot of opportunity and am hoping for your input.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Robert,

I have rotated the image to make it easier to view.

.

Robert,

1. The polyethylene vapor retarder on the wall is redundant and unnecessary in light of the 1 1/2 inch thick Thermax insulation directly behind it. When poly is put beside rigid foam like this, it does no harm; nor does it provide any benefit.

2. The designer has indicated an incorrect R-value for 1 1/2 inch Thermax. The R-value is about R-9, not R-3.

3. I think it would make a lot more sense to put the Thermax on the exterior side of the wall rather than the interior. That would give you an opportunity to include furring and a rainscreen gap, which is now lacking. It would also help keep the wall sheathing warm, reducing the risk of wintertime condensation or moisture accumulation in the stud cavities.

4. The insulation on the crawl space ceiling -- fiberglass batts with exterior poly -- is a recipe for disaster. That puts the poly on the cold-in-winter side of the floor assembly, which is backwards. If you really want to insulate the ceiling of a crawl space, use rigid foam under the floor joists, with no fiberglass batts between the joists, or use closed-cell spray polyurethane foam. Better yet: create an unvented conditioned crawl space with insulated walls. More information here: Building an Unvented Crawl Space.

Thanks for your input, Martin. Would sips or some other entirely different approach offer both energy and construction cost savings?

I forgot to indicate that this project is in deposit NY. Zone 6-a? R value adjustment?

Robert,

Q. "Would SIPs or some other entirely different approach offer both energy and construction cost savings?"

A. That's a broad question. SIPs work well, as long as the SIP seams are carefully air-sealed, and as long as the builder includes a rainscreen gap between the siding and the WRB. However, they are unlikely to offer construction cost savings.

A great many wall assembly types would work better than the one you proposed. You might be interested in reading Six Proven Ways to Build Energy-Smart Walls.

Finally, I don't understand your last question: "R-value adjustment?"

Martin- that R-value adjustment question was in regards to the fact that this project is in Deposit NY. I thought that might effect the thickness of the thermax. I believe that is in the 6a zone?

Robert,

Your drawing shows a layer of Thermax on the interior of the wall, not the exterior of the wall. There are no minimum R-value requirements for interior Thermax. You can make it as thin or as thick as you want.

If you choose to install rigid foam on the exterior of your wall, you have to meet minimum R-value requirements for the rigid foam. More information here: Calculating the Minimum Thickness of Rigid Foam Sheathing.

My comment on the "incorrect value" for the Thermax referred to the fact that your designer wrote "R-3" in parentheses after the words "1 1/2 in. Thermax rigid insul." That is incorrect. If you choose to install 1 1/2 inches of Thermax -- and you can -- you should know that the R-value of that product is about R-9, not R-3.