High Electric Bill with Heat Pumps

First, thanks to all who have helped build this forum knowledgebase through questions and particularly answers to those questions. Particular big shout-outs to Dana and Martin for sharing their expertise and helping inform members.

I was shocked when I received my electric bill ($700) yesterday and am trying to make sense of it and am looking for some guidance as, based on this electric bill, the cost of heating my house with ASHPs (plus 50 gal electric water heater) appears to be more expensive than it was to heat my house with a 50 year old oil boiler (plus oil indirect heating of domestic hot water).

For background on my setup, I have two outdoor units (MXZ-3C30NAHZ2) connected to three indoor units. These were installed in March 2019. One outdoor unit is connected to (1) a 9k basement head (2) 12k 1st floor den/kitchen head and (3) 9k 2nd fl master bedroom head. The other outdoor unit is connected to (1) 15k 1st floor living room head (2) 6k 2nd fl bedroom head and (3) a 6k 2nd fl guest bedroom head. I really don’t turn on the 6k bedroom units much for heat since they get heated a lot from the first floor heat traveling up through the house. The manual J on my home in Sherborn MA has the heat loss at 56k BTU/hr at 6F. My home is a two floor colonial built in 1968. It is 3400 sqft with a finished basement that sadly is not insulated or airsealed. I had the attic rafters and gable ends sprayfoamed to R38 a year ago. The 1st and 2nd fl walls have R13 batts in them. Windows are original single pane w/ storm windows. The outdoor unit connected to the head in the basement runs a lot; the other outdoor unit runs intermittently, even at 30F. Please also note that the oil boiler indirectly used to heat my domestic hot water using an electric hot water tank as a storage tank; I disconnected this and wired it up to now heat with electricity a couple months ago to be completely oil-free.

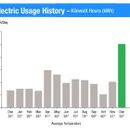

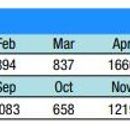

Everything has been great until this last electric bill that hit $700. In summertime the ASHPs performed beautifully and saved me quite a bit of money over the 15 SEER ducted central air system I used to use. The shoulder heating months (March, April, October) were fine too with electric bills that were about 1600 kWhr or less (please see attachments for monthly breakdown of electric use). Based on history, I’d say our base electric bill without heat or AC is 900 kWh/month. Add in electric domestic hot water and we should go to about 1350 kWh/month.

I went back to my oil record from last year before the ASHPs were installed and during one of the coldest periods of the year (08 to 28 January 2019), we used 112 gallons of heating oil over the course of those 20 days (810 HDD with a base temp of 65F, for a daily average of 40.5 HDD). Backing out let’s say 20 gallons of oil for domestic hot water, that leaves me with 92 gallons / 810 HDD = 0.11 gallons per HDD. Assuming 75% efficiency of the oil boiler, that gives me 11,517 BTU per HDD: (139,600 BTU/gal)(0.11 gal/HDD)(0.75 efficiency).

This last bill of $700 would be even more had it not been for my 14.4kW solar array that produced about 500 kWh during that billing period. Adding this to my bill would have me at about 3500 kWh of consumption from 11/6/2019 to 12/6/2019 (was billed for 3000 kWh of use). This period of time represented 969 HDD for a daily average of 31.3 HDD (assuming 65F base temp). FWIW, both units went through a number of defrost cycles over this period. Backing out the above baseline of 1350 kWh, this has me using 2.2 kWh per HDD [(3500-1350) / 969]. So, to hit this 11,517 BTU per HDD heat loss mark means I assume a COP of about 1.5… (3,412 BTU/kWh)(2.2 kWh/HDD)(COP) = 11,517.

A 1.5 COP is totally unacceptable for a 35F average and cold climate Mitsubishi equipment. I have set my house temp a few degrees higher with the ASHPs than I did when we were burning oil, but this still seems very wrong that the electric bill is so high. Does anyone have a sense of what is going on? I believe my math is correct. How can I spend about $500 on ASHP heating costs in Nov and early December??

Thanks for listening to the rant, any offered perspective and answers, all!

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I suspect an improper refrigerant charge level, and/or an improper Manual-J.

Why do I suspect the Manual-J?

>"The manual J on my home in Sherborn MA has the heat loss at 56k BTU/hr at 6F. "

--------------

>"Assuming 75% efficiency of the oil boiler, that gives me 11,517 BTU per HDD"

11,517 BTU per HDD = 480 BTU per degree-hour. At a presumptive heating/cooling balance point temp of 65F and an outside design temp of +6F you have 65F - 6F = 59F heating degrees.

59F x 480 BTU/F-hr= 28,320 BTU/hr.

That's literally half the 56K indicated by the Manual-J. While it's common for fuel-use derived heat loads to come in a bit under a properly executed Manual-J, it's not going to be off by 100% (or 50%). Even if the boiler was really running 85% efficiency, either the house wasn't being fully heated with the oil-burner, or the Manual-J was performed with VERY conservative (rather than aggressive, per the Manual) input assumptions.

But even with gross oversizing on the heat pumps it should still deliver better efficiency than that if properly charged, with a "set and forget" approach to the temperature settings rather than deep setbacks.

Thank you very much for the reply, Dana. I was definitely worried about the Manual J being oversized because it had been done by a geothermal company I was considering a year ago that I've since pieced together is known for oversizing their equipment. That, and the cycling of my outdoor units at temps in the 30s when heating or 80s when cooling.

However, as you pointed out, this alone should not explain the high electric bill. I'll get the ASHP installation company out to check the refrigerant levels. Hopefully they are off and this helps ameliorate the situation. If they're not, I suppose part of the problem may be my uninsulated basement that appears to be the big heat hog (the basement indoor unit runs constantly, but the area does hold temp). I used to set the basement at about 60-62 when we were on oil and then boost the temp up when we sought to use it. I now use the "set it and forget it" approach you're supposed to with ASHPs and set the basement to about 68 (also use the "set it and forget it" for the rest of the house too).

One thing I'm also working on is installing some of those Panasonic Whisper exhaust fans around the house to increase airflow, along with reversible ceiling fans. Once done, I'm hoping to shutdown the outdoor unit connected to the two smaller bedroom indoor units and the living room unit and use it as backup during extreme temps since my other outdoor unit has an indoor head on each floor, including the basement.

$500 for heating from about 06Nov to 06Dec is just silly tho, so let's hope the refrigerant is off and that improves things while I continue to do further airflow and insulation upgrades.

>$500 for heating from about 06Nov to 06Dec is just silly tho

Is your house in Mass?

Ours is in Wisconsin and had that cold snap at the end of Oct and beginning of Nov, so I'm thinking our temps here are similar to Mass if I remember right. We did a cost comparison between the old heating versus the new:

Nov '18: electric resistent hot water, LP gas furnance, original 1930s basement windows, 1980s weatherization

Nov '19: heat pump hot water, ductless minisplit, (LP furnance as backup and kicks on when temps <15F), replaced basement block windows, airsealed basement, insulated & airsealed roof/ceiling

The electric usage difference was a whopping 1 kWh:

Nov '18: 468 kWh

Nov '19: 469 kWh

Diving deeper, our utility's data makes this comparison look pretty fair:

Nov '18: 38F avg temp, 687 HDDs

Nov '19: 37F avg temp, 752 HDDs

>I used to set the basement at about 60-62 when we were on oil and then boost the temp up when we sought to use it.

I don't bother heating our basement and there is no insulation (yet!) between our 1st floor and basement but ours is 2' thick field stone foundation so it's temp is rather steady. Why do you heat your basement to low 60s? Is it finished/semi-finished?

Ah, I see now that I had sped read and you already answered my question:

> It is 3400 sqft with a finished basement that sadly is not insulated or airsealed.

Well ... I love my fellow Americans but the larger house movement and finishing basements is not something that I agree with b/c of these problems. The idiom 'bigger ain't better' rears it's ugly head. Our house has just 3 head units, and Dana helped with sizing calculations for it (36k), and our family decided to stick with the size that American families lived with in the 1930s when our farmhouse was built: 1300 sq ft.

Ya, the house (Massachusetts) is a bit bigger than what we need, but we bought more for the location. It was built 50 years ago and one of the previous owners clearly skimped on the finished basement job. We use the basement a lot for the kids play area, office, laundry, etc so not heating it is not an option.

That's ridiculous that following the heat pump install you only used 1kWh more compared to last year. You must have decreased use elsewhere as those numbers are too good to be true; whereas as mine are too bad to make sense. I'll keep the board informed on the troubleshooting. Again, hopefully a refrigerant charge issue as it was a lot cheaper to heat with oil using a 50 year old boiler.

I'm near Sherborn, MA and I heat my house with 5 Fujitsu ductless heads. Your $700 electric bill certainly seems high but it will spike once the temps start to really drop.

Just for comparison my house is about 2200Sf, insulated to the 2009 IECC specs. November is usually about $150, Dec $250, Jan $375, and Feb $450. It was worse when I had an electric resistance water heater but I switched to a HPWH recently. One minor thing to check would be to make sure all your filters are regularly clean. I definitely notice a decline in comfort if I forgo cleaning the filers. I doubt this is the main cause of your problem but it could certainly effect efficiency.

You could look in the Mitsubishi install manual to see what the max lineset length is for the precharged refrigerant.

The main issue is that you are in a huge poorly insulated leaky house. Insulate the basement walls to R20 before it gets colder, and do everything you can to make the drywall air tight for the winter. Next year come up with a plan to take the walls from R13 to R40 nominal. I would also take the attic from R38 to R60.

It does seem like consumers should specifically be contacting energy efficiency specialists with no financial interest in heating systems or solar panels or any type of gadget otherwise. The past is the past, but if you had poured those 10's of thousands of dollars into an R20-40-60 retrofit you'd be a happy camper right now.

I don't see an "R20-40-60 retrofit" being feasible on an existing 3400 SF house that is't already undergoing a full remodel.

First step should be to call your HVAC contractor and make sure all the units are operating properly.

Yep, the HVAC guys will be happy to receive a service call.

Thank you for the responses, Jon A and Nathan. Yes, I am worried that if I'm spending $500 on heating for Nov, what will happen in January. I cleaned the filters (they weren't very dusty) and I'm well within the max lineset length per head and overall for each outdoor unit.

Based on my reading here as well as other sources, having a house insulated as I do (other than the basement) should not prohibit one from using heat pumps. In fact, it sounds like it is more difficult to size right when your house is really well insulated and sealed and it is that situation that results in lots of cycling.

My 1st and 2nd floor are very comfortable with these ASHPs and those room heads do not need to constantly run to hold temp. The basement has cold spots tho and almost constantly runs but the basement head never shows those two lights indicating it is running hard to meet temp set point. I also supplement the basement with a 1500W resistance heater and this evens out the temp down there. The outdoor unit connected to the basement pretty much constantly runs below 45 degrees or so, but almost never sounds like it is working very hard unless we're in the teens.

I dunno, even when running hard with temps in the teens (a scenario where all three indoor heads should be calling for heat) the COP should be around 2.5 or so. I just can't make sense of what appears to be a COP of 1.5 that I got in November.

Keep an eye on that electric resistance heater: if it runs a lot, that’ll be a big contributor to your high electric bills. A 1,500 watt electric resistance heater is going to use 1.5kWh for every hour it’s on. If it runs continuously, that’s 1,080 kWh per month. I don’t know what your electric rate is, but if it’s 20 cents per kWh, for example, you’d be spending $216 every month just to run that heater.

It might be better to install a circulation fan to help even out the temperature in your basement if the minisplit has enough heating capacity but just doesn’t heat the space evenly. A fan will be much cheaper to run, and will let your heat pump do all the work of actually heating the space.

Bill

Good point and something to watch out for. Thank you. I don't run it all the time, only when down in the basement and using the office space, but I definitely intend on installing a Panasonic Whisper exhuast fan to circulate air between the main basement living area and the office area (separated by a door we always keep open). Just haven't got to it yet. Bit by bit I'm making my way through airsealing the area too and will eventually use EPS to insulate the exterior foundation walls.

> "Based on my reading here as well as other sources, having a house insulated as I do (other than the basement) should not prohibit one from using heat pumps. In fact, it sounds like it is more difficult to size right when your house is really well insulated and sealed and it is that situation that results in lots of cycling."

It seems like you have misunderstanding about what causes cycling and the resulting hits to COP. It's not good insulation (a good thing, always!), it's oversized units.

But get the contractor out to lo0k at the charge, and to talk about the unit sizes. If they are any good at all, they will not want a customer in your situation, and will look for ways to fix. it.

I would install an electricity monitor on each outdoor condenser. I use a Efergy engage and can see electricity consumption with a 15 second refresh rate on my phone. I can watch in real time both my units modulating up or down. Seeing the live consumption has allowed me to find what set points and fan settings to run mine at max efficiency.

I ran my 2 12k units the entire month of November at 70 and they used 448 kwhs. My house is a 1958 1800 sqft split level with some significant air sealing and insulation done.

Also, the Midea service manual for my unit makes reference to current operation power and has KW symbol but that feature appears to be disabled in the US market. Would be great if manufacturers would incorporate that into their units.

For the period spanning 01 October through to today, our two 12,000 BTU/hr ductless mini-splits which have thus far supplied all of our space heating needs have consumed 894 kWh (fifty-one year old, 2,900 sq. foot Cape Cod).

Collieguy-

1) What do you use for these reports and tracking? Really cool.

2) How many square feet per head do you have? That seems impressive to cover 2900sf with only 2 heads.

Thank you for the catch of the error of my logic. I guess I was just looking to make sure the heat pumps were modulating and not cycling.

Got in contact with the installer and they are coming out to do a visit soon.

There is an alternative ap for the efergy that is far superior then the Engage ap. Download the monitor for efergy engage by Daniel Stone.

Here was my combined usage of both my units for Nov.

Thanks everyone for all the replies and great ideas.

I will get an energy monitor. I was looking at Sense as the top candidate since you can monitor individual appliances and equipment, after spending enough time working with the Sense AI to identify them.

I'm also wondering if I'd be better off not using the "set and forget" ASHP approach in the basement since the heat loss is bad there. Instead, either go back to oil heat for the basement until I upgrade the airsealing and insulation and only turn up the heat when in use for the time being or do the same of holding a lower temp with the ASHP and then turn up when needed.

This also made me think that perhaps what we used to do when on oil (hold temp down in the basement around 60 and only turn up when in use) is biasing my fuel-use based home heat loss calculation to be less than it truly is. The calcs I did previously assumed I was holding the house at 65F constantly through last heating season, but I wasn't. I setback the temp at night when sleeping, while away at work during the day, and in the basement when not in use. I varied some of the parameters used to calculate my heat loss and went more conservative (assumed lower base temp for HDD, and higher oil boiler efficiency of 80%,) and I go from 11,500 BTU/HDD to about 14,500. Given that and the about 2100 kWh spent heating the house and basement to 68F constantly through 998 HDD (boosted up from 65 to 68 base temp to reflect the new set temp of my home w/ the ASHPs), I'm looking at a COP of closer to 2: (3,412 BTU/kWh)(2,100kWh)(COP)=(998 HDD)(14,500 BTU/HDD). Still not great for a period of time with a 35F average temp, but better than 1.5.

I’m pretty sure Sense doesn’t work well with heat pumps and from what I’ve read I wouldn’t recommend it. You want one that has individual CTs that monitor select circuits.

Good info. Thanks a bunch. I'll look for a monitor that will do this for me as monitoring the heat pumps are clearly the priority.

I have this one and am pretty pleased with it (the 32 channel GEM, not the one shown on the home page):

https://www.brultech.com/

I like the fact that it's not web dependent, which most of them seem to be. It has its own local web server, with the option to connect to various online apps.

I can confirm this about Sense. I have had it installed for about 2 years. It's great for real-time whole-house monitoring and total usage (I don't have a smart meter yet). But it gets confused especially on heat pumps when the load changes with lower temperatures. It's not a good option if you want to see for sure what a specific device uses during the day and/or month. I would definitely go with something that can monitor specific circuits. 25% of my overall usage so far this month is categorized as "Other" because it isn't sure.

Ben

I avoided the Sense. Totally understand that they're a startup local to Mass but that work was done with big tech that has little interest in developing software in a way that anyone can easily extend and customize (aka. Sense worked with Amazon and Phillips who are not known for their friendliness to opensource software collaboration). https://venturebeat.com/2019/07/29/sense-raises-10-million-more-for-ai-that-monitors-energy-use/

I went with IoTAWatt. https://iotawatt.com/#about

Johns3km,

I import the data extracts from our Efergy TPM meters and the MazoutMan monitor shown below into Excel, and combine this with the temperature readings supplied by our Netamo weather station. This provides a (hopefully) reasonably accurate guide as to home's energy performance on an hour-by-hour basis.

By way of background, in the year prior to our purchase, the previous homeowners consumed 5,700 litres of fuel oil and 12,300 kWh of electricity. With that in mind, we gutted the house, re-insulated and air sealed; installed new Pella Architectural series windows and doors; replaced the original heating system with a SlantFin boiler, indirect water heater, and Tekmar Control system; and added a heat recovery ventilator. That got us down to just over 2,000 litres/year. Subsequent to that, we installed our two ductless mini-splits and began heating our DHW with a Nyle Geyser RO heat pump water heater. Today, we use roughly 200 litres of oil a year for backup purposes and about 9,000 kWh of electricity, all wind, solar and low-impact hydro courtesy of Bullfrog Power.

The mini-split that serves the lower level will keep things at a fairly stable temperature throughout much of the winter, but the main floor unit is somewhat undersized and once temperatures dip below -10°C I'll periodically turn on the boiler to lend a hand. Temperatures on the main and upper floors are far from uniform without the aid of the boiler, but that's an acceptable trade-off in light of the environmental benefits afforded.

Collieguy- Have you found as well that these units dont really short cycle like people think? Both of mine will just modulate to min output around 200-250 watts and just stay there for hours. I have never seen the compressor turn on and off rapidly in a short time. It appears at least with my Gree and Midea they have some sort of algorithm to not short cycle.

Here is a snapshot of what both my units will do when they reach close to the setpoint. The spikes at min modulation are for oil control.

Thanks for the tip of the Efergy app.

This past Tuesday was quite mild for this time of year, and I did notice some short cycling, especially of the lower level unit. You'll see its consumption briefly rise in response to the operation of our Nyle HPWH which is controlled by a timer that allows it to recharge once a day between 03h00 and 06h00. Under low load conditions, they draw around 270-watts, but will drop to 25 or 30-watts when loafing about.

What kind of splits do you have? I have never seen mine operate like that and I have been monitoring them for over a year.

I am also monitoring my supply and return air temperature on both my units as well. One of my units had a small refrigerant leak on a flare fitting and it was as clear as day watching the performance drop off. These things drop off like a cliff if they dont have the exact refrigerant charge.

Its easy to make a supply temp chart compared with outdoor temperature and compressor power. If your losing refrigerant it easy to see.

I also monitor the monthly average supply temperatures. These units will run pretty uniform and if your losing refrigerant you will see the average climbing down rapidly.

They're twelve year old Sanyos with an HSPF of 9.3. The main floor unit was to have been replaced by a similar size, high efficiency cold-climate model that reportedly supplies 80 per cent of its nominal heating capacity at -30°C and that would theoretically trim our home's energy requirements by a 1,000 or so kWh a year (14.0 HSPF), but that's been pushed off until the new year. The Sanyos were fairly good performers in their day, but they struggle to keep up when temperatures dip below -10 °C, and pretty much pack it in at -20°C.

The installation company is coming out to check the refrigerant. Yeah! Will report findings when available.

I also went back over my Manual J and saw that out of the 55,850 BTU/hr load estimated, 6,000 BTU/hr was attributed to an HRV and another 7,700 to ducts. Backing those out gets me down to about 42,000 BTU/hr. I went back and redid my fuel consumption based Manual J with some assumptions that I believe are closer to the truth and I get about 37,000 BTU/hr.

Makes me realize I would have been better off with one MXZ-4C36NAHZ and runnings ducts for the second floor rather than two MXZ-3C30NAHZ2. Argh.

As a follow-up, I had the installer come out. They pulled the refrigerant, weighted it, and recharged with fresh 410A. However, the original was the factory charge for each outdoor unit and they both weighted at exactly the value they should.

I installed Iotawatt power monitors which are fantastic. Thanks vap0rtranz. I've been fiddling with the settings of the heat pumps (fan speed and which units to turn on) and found that bumping up the fan speed definitely decreases power consumption. I was using auto, but it appears auto typically operated somewhere between quiet and medium speed. I use high or very high while we're sleeping or away and that is helping.

I also have continued on my basement airsealing project and that is improving the load for my basement head. It actually now turns off from time to time and won't run so hard when on.

What is curious is how I'm seeing some short cycling with my first floor heads, even at temps in the 20s. This didn't used to happen when I kept the fan speeds at auto. Now that I've bumped up the fan speeds, they on average draw less energy to heat our main floor. I'm attaching a graph of power consumption from today which has gone from the low to mid 20s up to almost 30 degrees outside currently. Note how I'm getting power cycling on the "SouthHeatPump" starting around 9am this morning. What is weird is the cycling goes from zero consumption back up to between 1.5 and 2kW then back down again. Why isn't it instead modulating down? The only head I have running on this guy is the big 15k head (I didn't bother to turn on the little 6k 2nd floor bedroom heads because the heat is traveling upstairs well enough). Anyone have an idea why this is? I will be calling Mitsubishi to discuss this as well.

I'm posting a couple other graphs as well to give people a sense of how it has performed. It does modulate at various levels, but it also seems to have some strange behavior.

Basement air sealing and insulation does make a huge difference. Where I am the "natural" basement temperature is 50-60 degs. (Ground temperature)

Then the heating load tempered by the fact the ground is getting you part of the way to temperature.

If you don't air seal and insulate, your basement, instead of being a net positive, drags temperatures down all around. As with others, I agree that energy monitoring is key.

I've found that for my 24k Pioneer/Midea units without drain pan heaters they typically steady state around 400-500 watts in the 30-40 deg F range, but when it drops to the teens they are consistently drawing 1400-1600 watts! (They are rated for 5 deg F)

But we don't get a lot of those days here, so a cold temperature model would not make sense for me.

Also make sure to visually inspect when you are below freezing for a while. You'll find ice in odd places, and that ice build up will really drop your efficiency.

Thats not short cycling. Those dips are defrost cycles. The rise in the middle is the basepan heater coming on and the compressor speed increasing to melt the coil.

.Not sure how the Mitsubishi defrost cycle works but it almost appears that they are on a time based defrost cycle. I am just south in CT and looked yesterday and both my units only defrosted a few times. Yours seem to be spending a lot of time defrosting.

Here is a zoomed in shot of one of my units in a defrost cycle for comparision.

To the op... for 20s and 30s that's a lot of defrost cycles. Do you have a drain pan heater? You may need one.

Thank you for the replies user-7551473 and BFW577. So, those are not all defrost cycles. The defrost cycles are the ones that dip down but never hit about zero and then have that spike and then quickly ramp up again. The short cycles are the ones that go all the way down to zero and hold there for a bit (at least 20 minutes) before then ramping back up.

The first figure I posted, working back from the last time point, has the green heat pump showing about 7 short cycles. Starting at the beginning of that day though, both heat pumps are going thru defrost cycles. They're a bit hard to distinguish because the time scale is almost a full day.

I took another detailed look. They definitely seem to be short cycling. These are wall mounts right? Are you using the remotes for control? If you are using the remotes the temperature sensor is in the top return inlet. So its really reading the warmer layer of air up near the ceiling. You really need to control wall units of a seperate room thermostat. It makes a huge difference. I am guessing this is your issue.

This is a good suggestion and I wish it was the reason. I am using wall thermostat/humidity sensors along w/ the Kumo Station and Kumo Cloud equipment/programs. I control the units thru the Kumo Cloud smartphone app. Everything communicates via WiFi and Bluetooth. I've placed the sensors typically about 10ft from the wall mount units and 5ft off the floor so the temperature sensing is not the issue.

I'm banging my head against the wall because so many of the first-line troubleshooting solutions have been exhausted here. I'm starting to wonder if having two MXZ-3C30NAHZ2 outdoor units was a bad choice since they don't communicate with one another and I'd had been better off with a single larger multi-zone unit or a bunch of single zone units. I mean, the heat pumps keep the house comfortable but I'm not saving money over my 50 year old oil boiler.

I've attached another pic to show a zoomed in electric consumption signature for a power cycle on the green heat pump followed by a defrost cycle on both the blue and green heat pumps to help orientate people to what I'm observing.

Looking at your graphs I think both units seem to be cycling on at min and off for some time. If that is correct then we would need to conclude they are oversized for the load they are seeing given the current conditions.

Try turning off one or the other units maybe it will be able to carry the full load.

It is strange how often both units seem to cycle off at almost the same points in time. Maybe that is something like the sun come out from behind a cloud.

The other thing that seems strange is when others post their mini’s current draw graph. I recall seeing a 3 minute spike of full speed operation every 90 minutes to flush the oil back to the compressor.

Is the thermostat setting changing either remotely or on a schedule?

I think disconnecting the cloud and using the onboard electronic would be worth a shot.

Walta

The North Heat Pump has one indoor head on each floor of my home, but the warmed air doesn't get distributed well enough to keep the entire living space decently comfortable. I'm going to install an in-line duct fan (has 6 speeds all the way up to 700 cfm; will use existing, defunct ductwork from my old central air system) to circulate air on the main floor. We'll see what that does.

I keep the temperatures constant but I've started messing with the fan speeds, bumping up the speeds to save electricity when we're sleeping or away. I drop the speeds down while we're awake and in the rooms to reduce noise intrusiveness.

I'll call Mitsubishi technical support and show them the data and get their perspective. Maybe there is some issue with going through Kumo Cloud. I'll investigate that too. Thank you for the idea.

Cheers!

Something definitely doesnt seem right and I agree with Walter about possibly oversized equipment. Your efficiency is getting crushed ramping up and down like that. They dont appear to be running at any sustained low speed operation where the COP could 4+ times greater. Your modulation looks to be all over the place. They also seem to be defrosting excessively.

Here is a snapshot of my 12k Midea from last night. This is what a properly sized units modulation should look like. It ran steady at about 450 watts most of the night and I have it scheduled to turn up 2 degrees an hour before we get up. It then settled to its lowest capacity where the COP is probably at 6+.

Looks like your home needs about 950 BTUs/degree hour (56,000/(65-6). Since you are quite oversized, and your first floor heads are on 2 different compressor it's not an ideal situation.

Sherborn has a a low of 33 and high of 49 = average of 41F today. You'll need around 25,000 (68-41 * 950) BTU/hr. Ideally that comes from one compressor's heads. With your setup and house size that may be tough.

johns3km, thank you for the insight. Actually, the load is likely quite a bit less than that. That 56k BTU/hr at design temp includes 6k for an ERV and 8k for duct losses. My fuel-based design temp heat load is a bit less than 40k which is pretty close to the 42k when you back out those two factors I mentioned above. Yes, it appears the system is indeed oversized, even with my basement insulation and air leakage issues (which continue to improve as I work on them).

I wonder if I can get the installers to switch around the linesets so the main floor heads on are the same compressor. I think I'll need a seal of approval from Mitsubishi reps tho before the installer signs on to shuffling around the head-outdoor unit connections.

Yeah I would try and try and get the first floor ones on one compressor and your third most used head if there is room for it, I think you can get 130% of the rated capacity of the compressor, probably just a 6K and not the master 9k. Then all the smaller ones on the other compressor to use as backup when it's cold, and AC only to cool from your second floor down (smaller heads run longer and dehumidify better).

My question to your rep would be why did they install 57K worth when the load is 42k? Ideally I would try to get them all on one 3 or 4 ton unit.

I just checked the Mitsubishi operational performance table for the MXZ-3C30NAHZ and I am allowed a 15k, 12k, and 9k head on it. That could be my two first floor heads and the basement head. Ideally, I'd then use a ducted solution for the second fl and I guess keep the 9k master bedroom head since the MXZ-3C30NAHZ requires at least two indoor units connected. I feel this will be a bit of a battle with the installer though as these aren't simple modifications. If I can get a Mitsubishi rep though to, in writing, pan the current design and support the modifications then I probably have a good shot at winning.

I think Johns3k's suggestion is the way to go. If you can get all your main heating heads (basement/main floor) on a single unit, it will be running at higher load and should be more efficient. It would also stop the cycling you see. I don't know how your layout is, but if this is just moving linesets, it should not be too expensive, even if you have to cover the labour, it would be worth it.

Trying to switch the system over to a ductected cassette is way more expensive now, I think that ship has sailed.

Before starting this, I would do some measurements on efficiency.

Multi splits don't operate the same way as one-to-one units. The answer to how to run them efficiently is never easy. Since you have the power meter, one thing you can do a ballpark check of efficiency. This would only work if the head is not cycling on/off. With a decent thermometer measure the inlet and outlet temperature of the head to get the delta.

COP=(RatedCFMofHead*deltaT*1.08/3412) / CompressorPower

You can try this with combination of heads operating and also running each at full tilt to see if how the efficiency changes.

I am monitoring my return and supply temps and electricity and it would be cool to calculate COP. I am having some trouble with the forumula. Can someone help?

Here are my numbers. I just took these now. Its almost 50 out so the unit is putting out some strong heat and drawing very little.

CFM on high 306

Delta t on return/supply 34

Total wattage drawn 560 watts

306×34×1.08/3412= 3.29

3.29/560 watts is .005875?

What is the COP? 5.8?

Your COP is 5.8. My formula had the compressor power in kW (change the 3412 to 3.412 for W).

I calculated a COP on my 15k head of 3.15 when it was running by itself on my south heat pump last night with an outside temp of 47F. Expectation for this would be a COP of 4, given the manual.

Just now with it being 68F out, I calculated a COP of 3.8 on my 9k basement head when it was running by itself on the north heat pump. COP should be well above 4 with this weather.

Both are underperforming. Sigh.

We installed a Mitsubishi unit and extended the line set through the attic, the brand new unit started freezing up and going into defrost cycle a lot. It was a refrigerant leak in the coils. Mitsubishi unit had a defective coil off the factory floor.

Your HVAC installer did something wrong it seems. The tech charging your unit with refrigerant maybe lying to you and not charging them by the book.

Mechanics lie all the time, because doing things by the book takes a very long time.

I would sue your HVAC installer because they have messed up somewhere, and probably lied to you about something they said they did, but in reality cut corners and did not do it.

This sounds like a botched, HVAC job gone wrong.

It does seem like your unit is defrosting way too much which like Sevak said its probably still not charged correctly.

These are critically charged and need the exact charge down to the ounce. I dealt with a small leak on one of my splits and the performance plummeted off a cliff after losing just a few ozs of refrigerant.

How long were the techs there when they evacuated and recharged? Should have taken a couple hours to do properly.

Just curious what a system like this cost installed?

Akos, that's a great formula. Thanks for sharing. Would the rated CFM of the head be for the specific fan setting I am using at the time I perform the measurements?

When the techs and supervisor came out to check the charge it took them 4 hours to evacuate, weigh, and recharge. My linesets were all within the normal limits so the factory charge was initially used and this is the same amount (8lbs 13oz) they put back in with fresh 410A. They said the initial charge was spot on in weight for both units. I'm leaning now towards a setting being off or just a bad design.

The entire setup cost $28,500, but I got $10k knocked off in rebates and the rest was financed with a 0% MassSave loan. Figured it made sense to get top-of-the-line Mitsubishi equipment from a Diamond dealer when my 50 year old oil boiler and 20 year old central AC condenser/compressor could go at any time.

Thanks for all the perspective, everyone.

The flow rate should be from the data sheet of your head, there should be numbers for high,mid,low. Make sure your fan is set to manual and the air filter is clear. It is also good to fix the guide vanes to the least restrictive position.

For example, my 24k LG multi, when running a 9K head by itself, I get 21F delta @247 CFM using 853W. So the COP is around 2. I only use mine for cooling, so the low COP while heating is not an issue.

I still say your current graphs are abnormal even for over sized equipment. Consider running the equipment off the standard controller.

Walta

I think I'll give this a go when the weather gets cold again. Others have reported issues with Kumo Cloud as well. Thanks Walter.

Definitely take the "cloud" out of the perspective. Many of these integrations play with the set point and/or sensed temperature in a way that the heat pump will ramp up or down too quickly and thus operate in an inefficient mode.

Power monitoring has been a huge boon for understanding the system. So strange to see my 3-zone heat pump with just the 15k head running power cycling from a 2k load down to nothing then back up to 2kW again. It just isn't modulating. When the temperature is higher, it does the same thing but at about 1kW.

I've attached my floor plan with the room-by-room heat loads and the indoor head placements. After talking with a Mitsubishi rep, I'll get their statement in writing and then see what I can push the installer to do. I'd like to downsize the 15k living room head to 12k, the 12k family room head to 9k and then put those both on the same compressor as the basement head. Then just use an air handler and duct the entire second floor (which is already ducted anyways from the old central air system) and put that on the other compressor. I'd still need to keep at least one 2nd fl head tho since the other compressor is also a 3-zone unit.

Will report back with what Mitsubishi has to say about stuff.

Deleted

The max power consumption is rated a touch over 4kW for these outdoor units. I often only have my 15k head running on one of these outdoor units so the max should really be around 2kW under that setting. The fact that I'm seeing that load a lot is concerning when temps are in the 20s to low 30s and it is power cycling from that high load down to nothing then back up again. Under assumed COPs for those temps, it is very hard to justify the 15k head running essentially maxed out.

Calling Mitsubishi proved to be a futile effort. They only discuss basic tech support aspects with homeowners and require you to be a licensed HVAC tech to access their stage 2 tech support. Gonna need to go thru my installer or get a second opinion from another contractor to move forward on troubleshooting.

Have your tried running them off the stock Mitsubishi remotes? Not sure if Mitsubishi has a follow me feature where it uses the room temperature off the remote for control. Have your tried that? I have a return/supply temperature sensor on mine and the air is significantly warmer up by the ceiling. I set mine to 74 degrees to get a 68-70 degree temp lower in the room. Yours might be short cycling as the top layer of the air along the ceiling heats up really quickly.

AFAIK the Mits remote does not inlude a stat; if you use them you can expect more rapid cycling as the stat measures the air at the head intake- eg, the warmest part of the room up near the ceiling. The cheapest way to control them is with a room sensor connected to the cloud app.

Bill

I am in northern MA an installed an 18000 btu Mitsubishi on the main floor, so I have a few thoughts.

1) First, your basement heat load is not bad in December. Wait til February when it is going to be twice as high because the ground is colder. Need to address that space.

2) having the remote thermostats 10 feet away from the units is good but make sure it is not in the path of the air flow. I put my thermostat in the same open area but 20 feet to the side and it works well.

3) Did you say you had a heat pump water heater in the basement (or was that someone else). If this is the case, you could partition the basement so that the heat pump water heater exhausts into the cold side of the partition and the heat pump for the basement is heating a smaller portion of that space. To do that it might cost $600 to have someone build an insulated stud wall and heat only 60% of the basement rather than 100%. You don't need to heat the laundry room, just the office and kids play room, I am thinking.

4) As for air sealing there is likely a stack effect that contributes to cooling. In my case the air made it through floor boards into the first floor. That air eventually makes it up to the attic. To put an end to this in my house I lowered a few cords and hangers that were attached to the basement ceiling and then installed about 2" of closed cell insulation there, and a bit more on top of the sill. Needed to spend a few days with a contractor getting rid of dryrot before doing this but it worked well. The basement is no longer feeding so much cold into the rest of the house. The attic was also addressed, 9 years ago, it is the most insulated space in the building.

If you have basement walls that are exposed, consider having them patched and smooth coated from the outside next summer, even add an insulation product if possible down to 18 inches below ground level to keep out the cold...

The Mitsubishi unit I have is not good about having a "set point" of 60 degrees, I think the minimum is 61 or 62, but that might be the best way to keep the basement from breaking your bank. Also a pellet stove may be more economical than resistance heating for the days when you want to hang out in your basement.

The installer is getting a Mitsubishi rep to come out and evaluate. I'm gonna press for the two first floor heads and basement head to all go on the same compressor. This just makes too much sense not to do. Manual J says the area-specific loads will still be covered with some additional margin after shuffling the heads around in this way.

I think moving the temp/humidy sensors farther away / out of line-of-sight of the head fans is a very interesting idea. I know others have recommended I disconnect Kumo Cloud, but that also means disconnecting these remote sensors which have really helped to set the temp remotely, at the desired level, and have the system hold that temp +/- 1 degree F of set point. I disconnected the Kumo Station which, to me, seemed the more plausible issue.... that said, nothing changed after I did.

Shortly, I'll have the basement fully air-sealed. Basement was already finished with 2x4 stud walls w/ drywall over them when I bought the place. Some cavities have fiberglass in them, but a lot do not (maybe 70% do not). I'll also look to sprayfoam the ridge plate and rim joints this winter. In the spring I'll insulate the entire exterior of the foundation with reclaimed EPS to between R10-15 I can get from Insulation Depot in the town next door (Framingham).

Cheers all and thank you for all the ideas!

Here's a very telling energy monitor graph of my system (see attached). Starting from midnight the prior night until around 19:30 to 20:00 the outside temperature was in the low 40s and high 30s F. Then it dropped to around 35 degrees and continued downward from there to hold around 30F over night. This graph essentially shows the Mitsubishi heat pumps acting as two stage compressors over this temperature range, not as modulating compressors. They are simply responding to the outside temperature and not the heat load of the house.

This is what is killing my efficiency. If this is what Mitsubishi means by " INVERTER-driven compressor technology uses the precise amount of energy needed to maintain comfort conditions" then I feel lied to. Gonna be fun talking w/ the Mitsubishi rep about this. Hopefully the settings are off or they have bad controller boards and this is not truly how these multi-zone systems are designed to operate.

Your current graph clearly shows the control circuit you are using is very rudimentary and not capable of modulating the speed of the compressor. I understand you paid good money for this device at some point you need to admit it is a mistake and stop using it.

Also you need to shut off the north unit the temperature drops below 0°.

Walta

Thanks Walta. Yes, this is proving to be a mistake. If this indeed is how these units are designed to operate then I'm going to get Mitsubishi to pay for a reinstall using just single-zone heat pumps or if they don't, I'll seek legal action. Very disappointing.

Here is Mitsubishi's guide on multi head zoning.

http://meus1.mylinkdrive.com/sfiles/M_Application_Note_1036_Applying_MXZ-C_Multi-Zone_Systems-20190530.pdf

I just wanted to provide an update on my situation. I spoke w/ my installer yesterday (who has, throughout this entire process, really been receptive to my concerns and wants to make things right). We further discussed the strange "modulating" behavior where the outdoor compressors jump in power consumption around 35-34F from minimum (in my case, ~600W) to between 1.5 and 2kW, even though they had been maintaining setpoint in the house beautifully up to that point. This activity then leads to a stuffy house and power cycling on the compressors.

It turns out this is a real thing with the Mitsubishi multi-zone units and they are designed to ramp up the inverter frequency at that temperature, according to my installer based on recent conversations they've have with Mitsubishi reps.

I'll likely be getting my system redone using 4 single zone 1:1 units and this time I'll just duct the 2nd floor. This should be little to no money out of my pocket to do this as well. I'll chime in again when things are finally resolved, but I figured this was worth sharing because this means you REALLY need to size these multizones spot on to achieve comfort and efficiency.

P.S. The airsealing I've been doing in the basement has made a huge impact on comfort and energy savings. My house is another data point for how very important airsealing and insulating your basement is.

>I just wanted to provide an update on my situation.

Been following your post to figure out my own homes similar "mysteries", so ty.

>The airsealing I've been doing in the basement has made a huge impact on comfort and energy savings.

+1 here.

My upstairs was overheating until I made a change. Downstairs could be 68 while upstairs was 72+. (Downstairs has 2 12k heads, upstairs has 1 12k; rational being the downstairs is 1,000sq ft while upstairs is 700sq ft.) Going up the stairs, you could feel the heat hit your face (and vice versa, the cold hit your face going down). So major stratification of air was going on.

So I went around the house looking for suspects -- caulk gun in hand, construction tape roll on hand, can of foam in hand ... no wonder nobody wants to seal up a house :)

I finally found the mysterious culprit: a (re)leaking basement window. The window was original to the house (1930s), up for replacement until winter hit early and I couldn't finish all the basement windows, so I had taped up poly against this window's wood frame. Well the stack affect, or a mouse, or something had opened up the tape. I could feel a cold breeze coming in. So I foamed up the window frame from the outside.

Now, upstairs temp is the same or w/in 2 degress of downstairs temp. Much better than a 4+ degree stratification.

So I feel ya. Still trying to figure out my electric usage here -- not sure if it's leaky house syndrome or bad multi-split install.

Hi maheatpumpguy81, this was super interesting thread to follow and I learnt a lot from your experience, thank you for sharing! Sorry about all the hassle and puzzles you had to solve with your system. What did your final solution look like?

> This should be little to no money out of my pocket to do this

Out of curiosity, who paid for the redo if you ended up pursuing that option? I'm in a similar situation (oversized heat pump, short cycling, overheating, https://www.greenbuildingadvisor.com/question/is-my-mitsubishi-heat-pump-short-cycling) and trying to come up with a plan for when I need to seriously bring up reinstallation with my Diamond installer. They are currently suggesting MHK2s to solve the overheating. I'm not sure if that will address short cycling. Mitsubishi tech support (both, online chat and phone) weren't super helpful but did say that the system is short cycling a lot and resizing might be a solution.

I have an MXZ-SM36NAMHZ-U1 with an FS-18 heating a first floor townhome. Last year I used a pellet stove for my heat and used about 800 kw. This year from the mini split I used over 1600 kw. No help from the installation company, they say everything is normal, no leaks, levels are good. The submittal sheet under max power input it says 3080 w. I checked with Mitsubishi and they said that was power used per day, which would equate to about 92 kw a month.. I wish! Any thoughts?

Per https://www.acdirect.com/media/specs/Mitsubishi/mitsubishi-mxz-sm36-hyper-heat-specifications-sheet.pdf, looks like the unit uses between 3kW - 6.4kW per hour (I think those units are per hour and not per day but I could be wrong) based on outdoor temps.

For comparison, mine is around 2kW/hour and I consumed about 780kWh in January alone (that includes heat pump + all appliances (washing machine, dishwasher, etc). I live in the Boston area and average outdoor temp was 37.8F.

If your unit was working on the lower end of the spectrum, the heat pump would use approx 3x24kWh/day (=72kWh) and 30x72kWh (=2160kWh) in a month. This assumes that the heat pump is running at 3kWh per hour for the next 30 days, which doesn't happen in practice since it'll self modulate once your rooms are satisfied. I would recommend installing some electricity monitoring devices (I have Sense and love it, Emporia is another option) to better understand what's going on. Using Sense, I was able to identify that my heat pump was short cycling which caused excessive electricity consumption (see https://www.greenbuildingadvisor.com/question/is-my-mitsubishi-heat-pump-short-cycling).

@maheatpumpguy81

Wondering if you have any updates since 2019? Did Mitsubishi give you a solution? As we speak I am staring at a $400 bill for Nov 8, 2023 to Dec 7, 2023. Other than changing to a Single-Zone unit, did you find any other fixes?

Does anybody else have any solution(s)?

Thank you

$400 might be a lot might be a little...

what is the unit and setup?

how big and where is the house?

how well insulated it is?

how much per kwh are you paying?

I am curiously watching my new garage/barn with an apartment on the second floor we're living in. Both the garage and apartment are heated ad cooled by a heat pump. I also have a HPWH, a HP dryer and everything else is electric. My first full month was Dec/Jan and the cost was $250.

I live in coastal CT and I'm fine with a bill like that.

If I have to pay $3K a year for HVAC and all my other electric needs to live in an all electric structure, I think that would be great.

Wow am actually wondering why the high cost . I have a big home here in Forney, TX . Not too big but 4000sqft and i just spend max $250. .. Last month i paid $200. I have 3 indoor units of 6k+6K+6k Olivia series that i bought from south mini splits guys https://southminisplits.com/collections/3-zone/products/olivia-series-3-zone-6k-6k-6k-wall-mount-ductless-mini-split-a-c-and-heat-pump-with-wi-fi-adapter-and-installation-kit-option?variant=41200339386483 and everything works so well for me