venting a metal roof – worth it?

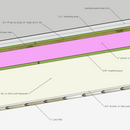

Hi folks – I’m a newer member and this is my first time posting a question. After reading in several places how I don’t want to create a ‘rot sandwich’ (and very quickly realizing that YES this is true), I came up with this assembly for the 2/12 single slope (shed) roof (cathedral ceiling) for my upcoming small house project. My intent with the furring strips is to create a pathway for drying if/when any water gets thru the standing seam layer. I do have details at both upper and lower eaves to facilitate continuous airflow. I’m in climate zone 6 (foothills of Northern CO) with about 17″ of precip per year. Of late I’m having doubts as to whether stepping the metal off of the upper sheathing layer is really worth the extra bother, given the fairly arid climate I live in. We can get some big winter snows and intense (& brief) summer thunderstorms, but prolonged periods of precipitation are rare, and its typically not that long after water falls out of the sky (in any form) before things are drying out again. I work in science, but am not a Building Scientist. Really interested in getting some different perspectives on whether I should keep this detail or not, as well as any other advice. Thanks.

(p.s. – although my drawing shows polyiso foam, I’ll likely use EPS or 2″ of EPS atop 2″ of polyiso instead)

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Joel,

There are differing opinions on this. Here is my take as an anti-strapper.

Any incidental moisture, or water from leaks, can dry or drain to the eaves through the profiles of the metal panels. A good synthetic underlay and layer of peel & stick membrane at the eaves, valleys and rakes will protect the sheathing.

Strapping the roof does a few things:

- It creates an air cavity, which encourages condensation. No cavity, no moist air to condense.

- If it is there as a drainage plane, how does that work at the eaves? How does it relate to the drip-edge?

- The strapping has to be horizontal to support the panels, blocking both air movement and drainage.

- Strapping makes the roof panels load-bearing, where without it they are supported by the sheathing, making them more susceptible to damage by workers or debris.

Hey Malcom - Thanks for the reply and great points. My furring strips actually run parallel to (& right on top of) each rafter, with the upper layer of roof sheathing sitting atop the furring strips to create a 3/4" air gap between the foam insulation and upper (1/2") sheathing. The SS metal roofing plane sits on top of and is supported by the upper sheathing. My drawings are a bit crude - I have added another one here showing the lower eave.

Joel,

That's a detail I haven't seen - and makes a lot of my comments redundant. The vent cavity below the sheathing adds a good drying path for the sheathing, and solves the problem of drainage at the eaves. I'm on the fence now. Sorry - I know that's not much help.

Joel,

I see Malcom has beaten me to first post. I may say a few redundant things, but there it is. I will note right away that you have not made any notes on how all this stack up is held onto the roof. My R-35 nailbase required 10" long screws. The crew only missed once that I ever found, but not everyone is so lucky. So on to the TL/DR part.

I built on the west slope for similar conditions, high, hot/cold - dry, 11" of precipitation. None of my standing seam sections are vented. The lowest pitched roof areas are membrane and unvented as well. I personally would go with a bit more exterior insulation and also full secondary sheathing in order to carry Grace high heat ice and water shield under the standing seam. It does happen to be code in my area, but I would have done it anyway. I feel that the slightly gummy character of the product helps to seal the screws for the standing seam clip mounts. The peak to eave coverage gives me (code ordered) peace of mind.

For the pitch you show, you can get butyl sealed clip lock seam, but taller fin height can be as safe and moves more freely. Narrower panels will oil can less, wider panels with rolled profiles will work too. Too wide will accentuate wind lift noise and oil canning. Expect there to be noise inside when it rains or hails. I don't recommend snow brakes. Don't have second level run off fall onto the lower roof. (ask me how I know)

I chose clip lock seams rather than permanent rolled seams for mixed reasons. Cost was first. Repairability next. Thermal expansion management. Seam height and pan width sizes, and finally the material I chose needs to be custom rolled. It is rather like continuous gutter in that sense, not super pricey. I would of course urge that you first look to ember control details for your location, a fact likely quite on your radar at the moment. A useful venting gap would require fine screening. The intersects with second story walls is another critical area if your design has them. My details include capping the pockets created by flashing to avoid ember capture.

I am of the opinion that much ado is made about venting under standing seam to no great purpose. In your detail, the 3/4" gap would be largely stagnant and only provide a space for condensation issues. I see 20-30 plus temperature swings between day and night, so despite the low humidity (avg 12-20 percent in summer) I still see dew on the roof if I get up early enough. It would form on the bottom of your standing seam if the gap is incorporated. I have not had any ice damming problems thanks to 8" of EPS above the first level of sheathing. The sun drives almost all melting, not heat loss from living spaces. Ice does form, but with no brakes in place it just slides down the roof carrying the snow with it. I wish I had extended the eaves another 10-12" to ensure the snow curls fell further from my siding. Too late now.

My own roof cross-section incorporates a synthetic roof paper at the first sheathing level to air seal the jump from foam to batt insulation. I have 2x12's so the R-19 batts stay clear of the low boxes for LED lighting. There are penetrations in the drywall, but as my design is meant to dry to interior I don't worry about it. My walls are similarly set up to keep all framing and primary sheathing well above the condensation risk temperature for a design temp of minus 16, interior humidity of 35%. In my case keeping the ceiling batts up in place was done with wire that jabs into the joists or by using mounts that look a lot like old fashioned paper spikes glued to the underside of the sheathing. The batts get stabbed onto them and disc washers then stab onto the spike ends.

Onslow: thanx for the excellent thoughts.

Yes, long screws into the rafters. And thanks for pointing me towards Grace HT product. I'm leaning towards covering the entire roof with that for the reasons you mentioned.

And 10-4 on the ember control via fine screening. I lost a home 12 years ago to wildfire, one that was designed to be fire resistant. When it's 1000 degrees outside and the windows go, nothing else matters because the fire is now inside the building. But with far fewer trees in my area now, future fires are more low intensity (as far as heat goes). So I'll def be screening those venting details.

Your and Malcom's comments about condensation on the underside of the metal due to the standoff by furring strips has me rethinking this approach.

Others have made good points already. But one question I have, why the EPS instead of just sticking with polyiso? Polyiso will have a higher R-value for the same thickness. If you’re worried about cold weather performance please note polyiso will pretty much always be higher R-value than EPS (down to ~15 degF average temperature between outside and inside of board).

Consider that you live in a desert your chance of getting wet and staying wet long enough for mold and rot seems very low.

Note vented spaces and exterior foam are best avoided in wildfires regions.

Have you seen this article?

https://www.greenbuildingadvisor.com/article/five-cathedral-ceilings-that-work

Walta

thanks, walta100!

You might want to look at a McElroy T-138 with ASV clips.

I will check it out