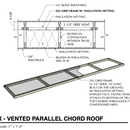

Venting a low-slope vaulted parallel chord truss

Hi all, first time posting here! I’ve passively gleaned much excellent information from you smart humans over the years, and would like to pose a specific question on a detail I’m exploring design options on.

I typically design low-slope roofs (2:12) in the PNW contemporary style. I’m well aware of the venting challenges in this scenario; most people seem to go for an unvented roof in this situation, but I’m really wanting to avoid foam products as much as possible.

I’m exploring an idea with my builder that he seems confident in, and I’m curious if anyone can poke holes in the functionality of it. I’ll attach a preliminary detail to this post… the general idea is to use a parallel chord truss with 2×6 top chords, and then create a frame system that allows insulation netting (or a fancier vapor-open product like Siga Majored, though not sure why this would be necessary) to be stretched tight between the trusses at the bottom of the top chord. My idea of how to do this is to build 22.5″x10′ (+/-) simple 2×2 frames on the ground, where it is easy to stretch a taut breathable fabric over them, then staple off. Then you install these fabric framed-panels between the trusses, flush to the bottom of the top chord. In this case, I’ll have a deep cavity to fill with blown-in cellulose (maybe 16″ per final truss design), and a nice 5.5″ air channel above it to vent. Any moisture that gets into the insulation has a nice easy, vapor-open path out, with relatively deep air space to move from low side to high side.

What do y’all think? The project in located in northwest WA state, near a river, consistent wind-movement (which I expect to help considerably with air movement in that space). Will this work? I know it involves some labor, but doesn’t seem too crazy to bang out these panel frames on the ground. The builder doesn’t seem scared to give it a go… I’m just wondering if there is something I’m missing in terms of the building science.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I'm not in the PWN so I can't comment on durability there, but around here it will work quite well.

Going with r38 batts sounds a lot simpler though. Not sure what dense packing buys you in this case. If you spec high density batts (either fiberglass or mineral wool) you won't have to worry about wind washing so you can skip any baffling except at the intake if you take a bit of care with the install.

With trusses get batts for metal studs as there are wider and avoids the gap where these is no truss framing.

aaronnw,

A 3/12 slope removes any risk, but It will work at 2/12 here in the PNW as long as it has excellent interior air-sealing, very few penetrations, and good intakes and outlets to take advantage of the deep air-space.

As usual, Akos has given you good advice about insulating options. 16" of cellulose is an awful lot for the PNW.