Ventilated cathedral ceiling baffle material sizing & barriers

Hello,

I’ll go ahead and apologize in advance if I’m cramming a lot of questions into a single post, but would greatly appreciate any and all input and feedback. I’ve done quite a bit of research on the topics and while sometimes I feel like I’ve got a grasp on the overall concepts, the details are vexing me.

Let me explain what I’m trying to accomplish. My house is a passive solar construction from 1983. The main body of the house is an open 4 story foyer with a cathedral ceiling. The back half of the house is closed off for conditioning on the first 3 floors. The back of the half-attic is, for all intents and purposes, open to the foyer. (See diagram 1). The foyer and, by extension, the attic space is unconditioned in the summer (other than leakage) and heated in the winter via a wood stove. We’ve recently had to rip out all of the insulation under the roof / cathedral ceiling because of animal infiltration and roofing damage – the fiberglass was trashed. Putting this all back together the right way is what has brought me here today.

The roof is a vented cathedral ceiling (vents at both soffit and hips). The rafters are webbed trusses that are 24″ on center and 14″ deep. I live in climate zone 4A, so I believe that I should have a minimum of R-38 worth of under roof insulation. I have also read that with a vented cathedral ceiling, I should have ventilation baffles. From reading here, I also surmise that it is much better to have these sealed as opposed to the cheap-o plastic baffles that you can buy at the big-box stores to prevent wind washing and to keep bugs / moisture out of the fiberglass.

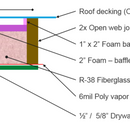

To this end, here’s what I have come up with (picture 2):

Underneath the roof decking (A), I am planning on building baffles made out of foil faced PolyISO. The stand-offs will be made out of 1″ board cut into 2″ strips to give it a full 2″ of baffle air circulation space (C). The baffle board will be made out of 2″ foil faced polyISO as well (D). The standoffs will be construction cemented to the roof decking and the board will also be cemented to the stand-offs to create an air tight seal. All seams will be taped. The baffles will run the full length of the rafter bays and the ends will be blocked with more boards and foam to seal up the ventilation channel.

On top of this baffle, I plan on installing unfaced R-38 fiberglass insulation (E). On top of that, a layer of 6 mil poly to act as an air / vapor barrier (F). Drywall will go on top of that (maybe) (G)

So that’s my total construction idea. Honestly I’m wondering if it’s overkill or if there is a good reason to go with these components. Here are my questions that I’d love input and feedback on:

1. Is the 2″ baffle board (D) overkill? In theory, this adds R-13 to the assembly, which can only help right? Am I actually getting a total of R-51 out of the assembly or is there some insulation R calculation voodoo that results in less value? Would I be better off saving money and going with a 1″ or thinner baffle board for (D). The foam thickness calculations I’ve read about say you need at least R-10 or better of foam to prevent interior condensation, hence the 2″.

2. Vapor Barrier: Part of the thinking behind for going with a 2″ baffle board was to prevent condensation on the inside of the assembly. The point of the poly vapor barrier was to provide true 6 side isolation to the fiberglass and prevent warm inside air from getting to the underside of the foam baffle in the first place. Bad idea? I obviously don’t want condensation anywhere inside of this assembly to rot the wood or degrade the fiberglass.

3. Drywall (G). The reason I put a ? here was because I’d like to know if I have options other than drywall. I know that the attic space, if it’s accessible, which it is, needs to be finished for fire-code. Foil faced PolyISO is in theory rated to be exposed to the interior without a thermal barrier. Drywall is going to be a real pain to install in the back part of the attic because of access (low ceiling and air handler is up there). A sheet of faced polyISO would be a lot easier to maneuver. This is just for the back part of the attic area. I’ll obviously need to drywall the ceiling portion.

Again thank you for any and all input. I’ve read just about everything I can find on this site and many others and feel that I know just enough to be dangerous.

Thanks

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Khari,

Your approach will work. Here is a link to an article that answers many of your questions:

Site-Built Ventilation Baffles for Roofs.

I don't think you need the interior polyethylene. Instead of worrying about vapor diffusion, it makes more sense to pay attention to air sealing. Here are links to two articles with more information on this issue:

Vapor Retarders and Vapor Barriers

Do I Need a Vapor Retarder?

Thanks for the quick response. I will definitely need to read up a bit more on vapor barrier vs. air barriers.

Do you any feedback on the baffle insulation? Is 2" polyISO worth the extra cost or would 1" or less be just as good in this situation?

Khari,

The short answer is that the baffle material must be stiff enough to avoid breakage. But there's more to say on the issue, so I urge you once again to read the article: Site-Built Ventilation Baffles for Roofs.

Martin,

I've actually got that article book marked. It is one of my main sources on the baffle construction in terms of using foil faced polyiso and paying careful attention to air tightness of the ceiling assembly.

Assume an air-tight assembly (both the ceiling and fully sealed baffle construction), where condensation and vapor permeability aren't considerations and the baffles are sufficiently rigid not to collapse or break.

So the question comes down to one of insulation R-value. Will the 2" polyiso add R-13 worth of extra insulation value (total roof insulation of R-51 from 38+13) or will the thermal bridging from the webbed trusses that are not covered by the rigid foam negate any additional insulation value and relegate the baffles solely to a ventilation mechanism?

Put in other words, does the material used for baffle construction add to the total R value of the roof assembly or should baffles just be thought of as mechanical ventilation corridors?

I don't know if the modeling and math has been done, but just trying to determine if it's worth the extra $$$ to go to the thicker and more expensive polyiso. If the answer is not really, then the cheapest, rigid, unbreakable, air-sealable materials would seem to be the best choice.

Khari,

As I wrote in the article, when it comes to choosing a material for making ventilation baffles, there is a little more safety in choosing a type of rigid foam that is somewhat vapor-permeable -- that would be EPS -- rather than a type of rigid foam that is vapor-impermeable (like foil-faced polyiso).

That said, for the reasons explained in the article, there are no reports of moisture problems when vapor-impermeable materials are used to make ventilation baffles. So I wouldn't worry.

If you want the rigid foam layer to provide the most useful R-value, I would install the rigid foam as a continuous layer on the interior side of the rafters. That way, the foam interrupts thermal bridging through the rafters. If you take this advice, you can use an inexpensive material like stiff cardboard to make your ventilation baffles.