Vaulted ceiling for a garage-to-music-studio conversion

Hello all

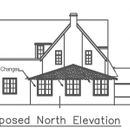

We have a double garage (8X8 mtrs) most of which we are converting to a music studio, here in the good old England. Garage is attached to the main house. We have a flat roof at the moment but would like a vaulted ceiling.

I have been looking into scissor trusses and they will work alright & with good price too. However, I would like to explore a ridge beam with posts, and then rafters so I can maximise the ceiling height. Current plan is for a warm roof with insulation on the outside but not tied to it..

With a span of more than 26 feet presumably I am looking at a LVL beam & fairly hefty rafters, and the posts. We can put extra padding to abut the foundations for support.

I would appreciate advice on how big & bulky the LVL & the rafters will be to plan the budget. Our loads are:

Tiles : 0.900 kN/sq M

Snow Load : 0.424 kN/sq M

Ceiling Dead Load: 0.250 kN/sq M

Ceiling Live Load: 0.250 kN/sq M

Cheers

Hemant

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

You really need an engineer to properly evaluate loading on such a long beam. The LVL manufacturers do have span tables though that will help you to get a rough idea. If you're just putting together a rough budget, go to your lumberyard and ask them to size the beam for you using either software or tables from the LVL manufacturer. When you get ready to build, I strongly recommend you have an engineer review your design first.

There is a *lot* of load on a ridge beam like this, and you need to make sure that all of the structure, including the foundation or piers that the beam ultimately bears down on, can handle the load.

I'd also consider the use of a steel ridge beam here. You can likely get a smaller profile using steel than you can using engineered wood products.

Bill

Zephyr7 - Thank you for your reply. Indeed I will get a structural engr to finally design however they are so busy here these days you can't get one of them to come & site visit quickly for love or money. By the time the project takes off in late June hopefully it will all be in place.

I will pop to a lumberyard & get them to price me & look at their delivery times etc.

Presently we have two 7X4 steel I-beams supporting the flat roof (on 6X2's). Both the beams are supported in the middle as well with posts, which we want to avoid of course. I will look into steel as well. Appreciate your advice.

On one side, the beam can take support from the house wall & on other side we were thinking of getting a pier up off the wall & attach it to foundation of course, or get a post on a pad of some kind.

Cheers

Hemant

I'm going to work in imperial units here. The rafters won't be a problem, you're only talking a 13' span. Approximately 2x8 or 2x10.

The ridge beam will be a whopper, but feasible. You're showing a total load of about 38 psf, for a load on the beam of about 500 plf. I used Weyerhauser's LVL table (western US version), which puts you near the upper limit of what they can accomodate. I show about a 5.25"x18" LVL.

As noted above, that's done using the span table only for a rough idea.

Gary thank you so much for taking the time to look through. Much appreciated :-)

Need to find out how much weight this sort of LVL will run to for 8.2 metres.

I need to look at Weyerhauser's tables. And do the metric to imperial units before that.

Cheers

Hemant,

Note that when an American like Zephyr/Bill talks about "lumber," he's talking about what you call "timber," not miscellaneous household junk taking up room in your attic or storage space.

Martin Cheers. And good one :-)

I gathered that & tried to reply in the same lingo. And didn't for a second confused the 'Lumber' Gary referred to with the spinal vertebrae either :-))

Hemant

For my education - presumably the 38psf estimated weight is for the coverings top & bottom (tiles, plasterboard, snow etc). However, how do I factor in the weights of the rafters themselves - does a certain percentage weight of the rafters in such designed gets born on the walls & rest on the Beam?

Cheers

The weight of the rafters and sheathing, basically all of the regular structure that forms the part of the building being supported is considered the "dead" load -- load that is always there. Anything else (people, stuff, etc.) is "live" load. You can look up that info from tables too. Basically work from manufacturer's tables for the beams/rafters/etc to put together your rough design for budgetary purposes, then have an engineer finalize the design prior to your build.

Earlier you mentioned supporting one end of the ridge beam on a post or column from the existing foundation. The ridge beam will present a concentrated load to that point on the foundation which may be a problem. Remember that having a bunch of joists attached at regular intervals along a wall distributes the total load over a large area of foundation and underlying soil. By using a ridge beam, you're taking all that load that used to be distributed, cutting the total in half, and putting each half on one small column on either end of the beam. Sometimes that will require a special footing in that area to spread the load out enough to avoid serious settling or cracking concerns.

Make sure you have that column setting onto something vertically too, even if your existing foundation is OK for the load. Do NOT try to bolt something to the side of that foundation wall! The shear forces the column will apply to any bolts like that will be very, very large and outside of the allowable shear range for normal fasteners.

Bill

Bill

Thank you for your detailed reply and taking the time. Much appreciated. I will await the structural engr & in the meanwhile keep doing my due diligence. If is too much trouble with the beam, then I will go with scissor trusses. I will lose some height but can try to reduce the impact by insulation under the roof deck but that is a different challenge in itself - insulating the scissor trusses effectively near the eaves.

Cheers

Hemant

Just a thought, but if you're maximizing space, what about a parallel chord truss? I get the expensive part, but if you think about the time factor, maybe there is a savings in the fact that the trusses go up quick.

Thanks Bird for the idea. I will discuss this with the truss designer. That will be easier to insulate as well I think.

Cheers

Hemant