Vapor protection in vented crawlspace

I read this very educational article when looking into facings in vented crawlspace insulation

https://buildingscience.com/documents/insights/bsi-009-new-light-in-crawlspaces

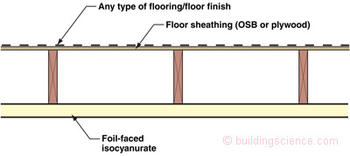

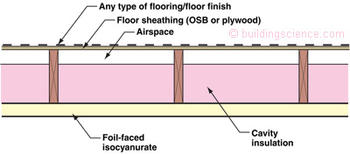

Figure 7 and 8 are applicable to me

What thickness of foam is required? 1″ EPS with facings has ~0 perm so I would think it would be fine to keep out vapor and keep the wood “warm enough”.

Unfortunately I already bought my fiberglass and it is non-returnable. It does not have room for an airspace, why is this recommended?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

James,

Joe L. suggested an air-space so the sub-floor would stay closer to the temperature of the room. He later rowed back that recommendation.

Good to know, thanks!

Do you think 1" foam is sufficient ?

It depends on how cold it gets in the crawl space.

What you have is a wrong side vapor barrier, usually the vapor barrier goes on the warm side. There's nothing wrong with it, but you have to take the step of having enough impermeable insulation -- IE, foam board -- on the cold side that it never gets cold enough inside of the impermeable for condensation to form. The colder it gets outside, the thicker the foam needs to be.

For each climate zone the IRC has standards for walls. While it may be that the crawl space stays warmer than the outside, the safest thing would be to use the standard for exterior continuous insulation in walls in your climate zone.

DC & Bill,

Martin - an advocate for adhering to the minimum levels of foam in walls - doesn't take the same approach for floors.

https://www.greenbuildingadvisor.com/article/insulating-a-wood-framed-floor-assembly

The comments are interesting.

Two related points - and I'm not necessarily advocating for thinner foam:

- We know walls with less than the required ratios work. They get used all the time in Eastern Canada. https://www.greenbuildingadvisor.com/article/rethinking-the-rules-on-minimum-foam-thickness

- Given the requirements for walls are based on a ratio of foam to permeable insulation, and that the floor will have a lot more insulation in its cavity than a 2"x6" wall, aren't we looking at awfully thick layer of foam?

+1 for going with the same thickness recommended for walls for your climate zone here.

I would use polyiso here for several reasons: Polyiso is easier to tape, and that's important when you need a vapor barrier, polyiso is more rigid, so won't sag as much when supporting insulation batts, and polyiso is likely easier to work with in this application due to less tendency to "chunk out" if you bump it around while maneuvering it into place.

The vapor barrier in this case would be the foil facer, which is zero perms, so the foam thickness makes no difference in terms of vapor flow with a foil faced polyiso layer as your combo foam and vapor barrier.

Bill