Vapor Control for Metal Roof Assembly

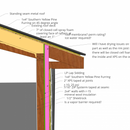

Good morning, my name is Lee and I have been remodeling a 1970s farm house about 30 miles southeast of Des Moines Iowa( Climate Zone 5). I have attached a sketch to help illustrate what my plans for the house are.

The walls will be the following:

-1/2″ sheetrock

– vapor barrier?

-2×4 studs with R15 mineral wool insulation

– closed cell spray foam on rim joist and above the double topplate

-7/16″ zip sheeting taped at all joints and caulked at penetrations

– Marvin fiberglass windows fixed to 2-3/4″ wood buck

-2″ 25 psi XPS foam taped at seams going from the sill plate on top of basement wall all the way to roof deck

-1×4″ southern yellow pine rain screen battens

-LP smartside

The roof whether vaulted or conditioned attic will be:

– 2×6 rafters

– 7″ closed cell spray foam covering the face of the joist at least 1″

-existing plywood roof deck

– roof underlayment ?

– 1×4″ southern yellow pine rain screen battens on 45 degrees

– standing seam metal roof

My questions are:

1- what is a good peel and stick permeable ( what is a good perm rating?) roof underlayment for a metal roof( high temp) that has a long uv resistance and long warranty?

2-are ice and water required at the eaves and valleys even with spray foam insulation on roof deck and roof battens above? If so will I have a drying issue with the deck?

3- Is a vapor barrier plastic required on the inside of the walls behind the sheetrock?

4- will I have drying issues where there is closed cell spray foam insulation on the inside and 2″ xps foam on the outside, like above the top plate and on the rim joist?

I know those are a lot of questions but, I figured that it would be better to ask them in the same post since the whole system has to work together and avoid single points of failure. Thanks in advance!

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Lee,

1. You don't need a permeable underlay on the roof deck (see rely # 4 below), just one designed for the high heat metal roof panels generate.

I'm not sure what the diagonal furring adds to your roof assembly (you will have no drying from below to vent). If the existing roof decking is in good shape, I'd install the metal roofing directly onto it.

2. Yes you should include I&WS.

3. No you don't need a poly vapour-barrier, but you do need an air-barrier. That can be the drywall detailed properly, the sheathing or the foam taped and sealed, or a self-adhered WRB.

4. Vapour-barriers on both sides are only a problem if there is a cavity in between. So while vapour-barrier on both the inside and exterior of a wall or roof can cause problems, sandwiching a layer of sheathing is fine as long as it is dry when they are installed.

5. If you find the spray foam for your roof is too expensive you may want to consider one of the other cathedral ceiling assemblies in this link: https://www.greenbuildingadvisor.com/article/five-cathedral-ceilings-that-work

Malcolm, thank you for the quick response.

1- So if I don’t need a permeable underlayment can I use the Ice and Water Shield on the whole roof? Also I included the battens to the design because of following reasons:

- I was under the impression that the deck had to dry to one side or the other thus the permeable underlayment and the air gap

- the battens would serve to correct any irregularities ( level for lack of a better word) the roof

- lastly the vented roof would hopefully help prevent ice dam in the winter

2- Thanks I will include Ice and water shield to the roof

3- I will be extra careful air sealing both the zip system and the XPS insulation

4- Thanks

5- Thanks

Lee,

You could safely use I&WS on the whole roof, but it would be overkill. A good synthetic membrane is fine everywhere but the eaves and valleys.

The deck only needs to have a path to drying where it is vulnerable to water vapour. With an impermeable underlay above and closed cell foam below the deck will never get wet.

https://www.greenbuildingadvisor.com/article/sandwiching-roof-sheathing-two-impermeable-layers

There is nothing wrong with adding the battens to flatten the roof deck if necessary. Make sure to leave gaps at the rakes to allow ventilation of the cavities that don't terminate at the eaves or ridge.

Thank you for all your help, I have a pretty good idea how to proceed now.

Your wall assembly is good except for the vapor barrier on the inside.

1. As far as a permeable P&S membrane, I would first talk to the roof suppliers, however, there are good companies to choose from, like VaproShield’s SlopeShield.

2. Yes

3. NO!

4. Take off that plastic and you’ll be fine.

If I were designing your roof assembly, I would change to replace the ccSPF for other R20 permeable insulation under the rood decking (Cellulose, fiberglass, ocSPF or mineral wool) and install 4”-2 layer R20 rigid foam board, with staggered seams.

Then you install the 1x4 battens (45° or spliced 180°) and metal roof.

FYI, ocSPF gives you the better coverage, specially between the webs, but use a brand with low global warming potential, if you can.

Armando, thanks for the response, I will check those products out. As far as insulation above and below the roof I have considered that option and I will look back to this options but there were a few reasons that made me choose the ccSPF:

1- the rafters are only 2x6 and I don’t know if I would have enough room for regular insulation and mechanical/ electrical

2- ccSPF would take care of all the air sealing on the roof deck

3- the living space that would be sprayed is about 2000sf, I also have a 900sf attached garage, a covered porch and all the overhands that would add at least another 1000sf to the above deck insulation area. With that said the cost of the extra insulation, the long screws and the potential extra metal trim on the fascia would probably be about the same as the ccSPF on the living area anyways.

-time would be another factor to this, ccSPF would be faster all things considered

Lee,

With 2"x6" raters probably the only viable way to use one of the alternative roof assemblies would be to fur down your rafters to get more depth.