Unvented Roof Assembly Best Practice/Method

Hello!

I’m in climate zone 6, 2/12 pitch, shed roof, building elevations attached.

I’m using Zip as a primary air barrier, prefer to use Rockwool for all my insulation (install myself possibly and/or with help from framing sub).

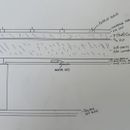

The roof assembly (PRELIMINARY drawing of this is attached, but incomplete, see specs for more detail):

-18″ exposed x-beams front to back

-2″ furring blocks to create electrical raceway that will be covered by t&g at finishing stage

-Certainteed MemBrain Smart Vapor retarder (planing for zero protrusions except fireplace/stove pipe, will lay inbetween beams and 2×8’s at framing stage)

-2×8’s perpendicular to beams (w/ R30 Comfortbatt cavity)

-Zip sheathing taped and tied into wall air barrier

-3″ Comfortboard 80 as continuous insulation (R12.6 leaves me a little short on ratio, I know, trying to keep the fascia from being 16″)

-Roofing underlayment (TBD)

-Furring strips for ventilated air gap

-Standing seam metal

My thoughts/questions:

1. The internet seems to question the application of Comfortboard 80 on a low slope roof, but I don’t like foam for several reasons, including wanting to maintain perm. Is this a good application for this product?

2. For my furring and air gap – I need to run my furring strips horizontal to support the standing seam. My roofer (amish manufacturer and installer) didnt like the idea of running them at a 45 degree angle. It seems like they would be best run vertically for stack effect and drainage. Is the answer to do a double furring grid air gap (vertically, then horizontally) or can I just run them horizontally and vent at sides?

3. Roofing underlayment – what do I do here for ice and water protection? I need permeability for my air gap to serve it’s full function. Underlayment on the Comfortboard 80 seems like it might be bad practice? I’m hoping to not have to do another complete layer of OBS, then underlayment, then metal, but it seems like that might be the safest???

Thanks in advance for any advice on these questions and any other thoughts or suggestions.

Best, Dan

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Dan,

"R12.6 leaves me a little short on ratio, I know, trying to keep the fascia from being 16″

Using permeable continuous insulation like Comfortboard 80 means the ratio isn't important, as the roof cans till dry to the vent cavity above.

1. Most low sloped roofs (and at 2/12 yours is just on the edge of being one) don't have ventilation. Those un-vented roofs are the ones that need impermeable foam.

2. You need the difference in height that vertical venting from eaves to peak gives you to move air. Horizontal furring won't be adequate on in its own.

3. Use the assembly you show and run a high temperature impermeable sheet underlayment designed for metal roofing on top of your strapping.

Thanks for the tip on ratio as it relates to permeability.

#3…I thought about this (underlayment over strapping) but I can’t dream up how the roof installer would go about laying the underlayment and metal roof on the strapping without messing up the underlayment.

And if I need the vertical strapping for air movement, there would have to be vertical strapping first for the air gap, then horizontal to support the metal, I assume, right?

Seems like it would be very difficult to roll out the underlayment (especially if it’s self adhering) then pull 40’ sections of metal onto the roof without good messing up the underlayment which would ideally be taut between/bridging the strapping.

Thanks again.

Dan,

The photo is of a metal working shop I built several years ago. It has strapping with a high temperature synthetic underlayment under the panels, which were 36 feet long and were easy to install. As the underside was exposed you could see the underlayment stayed taut after the roofing was put on.

Deleted

I think you are overthinking the assembly.

Bump up the purlins to fit the amount of insulation you need, you can even use I-joists if you need more height.

Run a sarking membrane over this, anything with decent perm rating works (ie house wrap or permeable roofing underlayment).

Install 2x4 on edge and run these out past the walls to form your overhang. This gives you the vent space you need plus your overhangs are now much thinner no matter how much insulation you use. The 2x4s will need to be anchored down to your top plates the same as any rafter for uplift.

Over the 2x4 you can put strapping or another deck for the metal roof.

This is a simple vented assembly that works in any climate and you don't need any expensive rigid mineral wool insulation. Heck, you can even loose fill or semi dense pack the rafters with cellulose.

Thanks Akos.

If I’m understanding you correctly, this drastically changes the aesthetic of the beams and such, correct?

Also, wouldn’t my assembly, with use of continuous insulation, be a safer bet as it will keep the sheathing warmer and reduce the chances of condensation Or does the additional R-value in the cavity essentially accomplish the same thing? Vapor still transfers…

Thanks!