Transition from REMOTE house to batt insulated garage on same plane

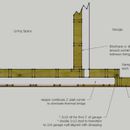

I am trying to figure out how to frame the transition from house to garage on a new construction home with REMOTE walls on the house, and batt insulation in the garage. I would like siding to continue on one plane across this transition. I did my best to draw a detail of my plan, which should be attached. A basic description of key components is:

House sheathing is wrapped in bituthane or drainwrap, which is continuous around the corner and between the living and garage space.

House is wrapped in 5″ thick neopor with 1×4 strapping, which continues on the exterior 2′ past the transition to garage to eliminate thermal bridging

The garage slab is 5 3/4″ wider than the foundation on each side, and for the first 2′ of garage (under the neopor that continues past the transition) there is a 2×12 sill. At the end of this short length of 2×12 sill, there is a pair of 2×12 studs aligned with the exterior of the strapping on the house. The 2×6 garage wall attaches to these flush with the exterior, and continues around the remainder of the garage.

Is this a solid way to accomplish this transition? Suggestions for changes or improvements?

Thanks for your time!

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Jim,

I don't really understand why you want to extend the 5-inch-thick Neopor insulation so that it creates a big wing into the garage. If you simply terminate the Neopor at the usual spot (so that it creates an ordinary outside corner), you'll be fine. It's no different from the other outside corners on your house.

Thanks Martin. It makes sense that I would be fine, in terms of eliminating thermal bridging, with a regular outside corner. Where I get lost is how to then transition to a garage wall that is aligned with the strapping.

If I turn the corner with the foam like any exterior corner, then I would be left with a 5 3/4" jog in the wall framing with neopor between the studs at my connection point. Maybe this would be fine...I just feel more comfortable with a wood-to-wood connection.

My thought was that by continuing 2' past the corner, I allowed room to get a couple anchor bolts up through the 2x12 sill, and could move the jog away from the corner and make the transition with studs directly attached to each other and without any bridging into the house.

I am attaching another picture that may be a good compromise. With batt insulation in the house, this seems it would still be a well-insulated corner, with minimal bridging, and maybe a simpler and sturdier connection than my initial drawing? Let me know if it would work.

By stating that you want wood to wood contact between an interior framed wall and an exterior framed wall, you have defined the problem in a way that avoiding all wood pathways through the structure is impossible. Your compromise drawing comes pretty close. The square of foam embedded in the garage wall doesn't accomplish much except making it harder to build.

How are you finishing the interior of the garage walls?

Not concerned about stud to stud connections between an interior and exterior wall, but rather between the exterior wall of the house and the exterior wall of the garage. The square of foam in the drawing is a little deceptive. There will be foam between the house and garage. In the drawing, the last sheet is notched around the stud where the house wall connects to the garage wall. You are right that this location may be easier to insulate with the roxul batts that will be in the garage wall.

Maybe one of my questions should be would it be structurally sound to just wrap the outside corner in foam (Neopor 18psi) like any other corner and then screw through it to attach the garage wall?

Garage will probably be finished in rough sawn shiplap, but haven't quite gotten there yet planning wise. Thanks for the help.

My choice of words was not very precise. I should have said a framed inside layer of a wall and a framed exterior wall. My point was that, assuming your building will have some windows and doors, the little bit of thermal bridging in your compromise drawing is very minor. The wood pathway from inside to outside is about 18 inches long, so it has three times the R value of the thermal bridges in a 2x6 wall. And, the cross sectional area is a tiny fraction of your wall. Avoiding this bridge is not worth doing something that is structurally questionable.

Good point - I agree. Thanks again.

Jim,

Is the house built yet? Have you actually bought the NEOPOR and/or insulated it with Neopor on the exterior? If not, I can likely steer you in a similar direction, but help save you a TON of $$$, and still employ the REMOTE construction technique. So much so, that you might be inclined to continue the REMOTE technique on the garage too.

NEOPOR is approximately $0.28 -0.38/bd ft delivered depending on where you source it - maybe even quite a bit more if you are struggling to find a supplier. Although it has a slightly higher R-value than EPS, you can source reclaimed EPS for around $0.9 - $0.12/bd ft, and can make up for the slightly lower R-value by just increasing the thickness very slightly.

I am doing this for my project and saved considerable money, even above the cost of batt insulation. It felt good to divert the EPS from the densifier and China - which is where the EPS was headed.....(to be turned into packing for Christmas toys probably)!

Even if you choose to stick with your plan, why not just overlay the garage wall over the Neopor, then replace the first wall stud with a single 2x12 and screw through the insulation to the (house) interior corner stud? You have no shear requirement vertically, and screws like Tru-Fast or LedgerLok can easily handle the connection. This way you isolate the house, can have a continuous WRB & insulation layer, and also line up the exterior walls.

I think your second plan is better, and also fine too if you "need" that wood-to-wood connection. I mean you second design has no more thermal bridging than you'll have at your window assemblies, you just interrupt the continuous WRB and insulation layer at the corner.

Good luck and let me know if want some leads on suppliers for either NEOPOR or reclaimed EPS.

Brad - thanks for the advice. Construction starts in June, so I have plenty of time to chase leads. The supplier I have been talking with is in the range you indicated for neopor. I have clearly not searched as thoroughly as I should have because I did not find anywhere near those prices for reclaimed EPS. I'll take all the leads you can give me. Thanks for your time and help.

Jim,

Insulation Depot is my go to place for reclaimed rigid foam products. Ask for Dave Volpe. Fantastic for reclaimed EPS. I've going with R-22 subslab, R- 37 basement wall, R-52 above grade walls, and R-70 Roof. HERS index of 2 (modeled/with PV). A estimated heat, cooling, electricity and hot water heating bill for the year of a mere $303! There is a lot of EPS in my yard right now, upwards of 130,00 bd ft!

For NEOPOR - depending on how much you need (read truck load) try going to directly to Perma - R. Best price anywhere. period.

Look to TruFast SIPTP screws to attach the foam. IF you have a way to support the foam from the bottom, so there is virtually no shear stress on the screws, you can put many more inches of foam on a wall than the current 4" allowed. I had it engineered so I was sure it would be safe for wind pullout.

good luck!