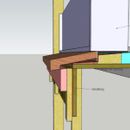

Traditional window sill for in-betweenie window

Trying to install a flanged window as an in-betweenie with a traditional sill detail (Traditional meaning thicker than the metal often depicted).

Using the GBA detail as a guide, https://www.greenbuildingadvisor.com/app/uploads/sites/default/files/Flanged%20window%20as%20an%20inbetweenie%20-%20sill.pdf

I came up with the image below.

A few things to contrast / clarify against the GBA detail:

1) The GBA detail only has the sloped rough sill to the exterior of the flange/2x ring. This is an issue I don’t have a great grasp on: the issue of where exactly the water ‘we expect to leak’ is gettin. I get that we don’t rely on the flanges, but beyond them where should we expect water to potentially get (and thereby need sloping and vapor impermeable flashing). This is the reason I included sloping on the 2x bottom ring itself.

2) Is there any way I could or should include ‘over insulation’ at the bottom (not shown in my detail). Perhaps for the top and sides, but not bottom?

3) The main difference here is the thickness of the sill vs the thin metal flashing shown in the GBA detail. I think I have enough room to get it in there, but I had considered needing to slope the entire plywood box for clearance (or use thicker material than a 2x for the bottom of the ring to get the window up higher).

Should this extended sill (be it cedar or some composite) be butted up against the flange of the window and caulked since there is still open drainage below it? Or forgo any sealing there? It seems like its pretty exposed save for the overhang created by the inset, and water will quite likely get behind it (granted the sloped and flashed rough sill is a safeguard for this).

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

1) I don't know where water actually leaks from, but I think you are onto something with sloping the bottom of the 2x ring. If we have a waterpoof material, best to make sure it directs water out of the building.

Following that train of thought, what is the advantage of wraping the pan flashing over the interior side of the 2x?

2) Not sure what you mean by over insulation

3) How are you attaching the extension sill?

3b) I think unless you are leaving sufficient drainage gaps, the extension sill should be sealed.

I am learning here with you, so hopefully some real experts will come by.

1. how or where does water get in? Flashing the rough opening is to move leaked water out regardless of where the leak takes place, including if the window unit itself leaks.

2. over-insulation at the sill - Over-insulation at the sill is just as effective as over-insulation at the jambs and head

3. sloped sill - think of any non-horizontal surface on a building as a roof. Choose materials and install them as you would a roof. When you use wood as aesthetic cover material or finish, gap it to be free-draining and more able to dry because of air movement.

Tyler,

I think your detail should work fine. You might want to cut a few grooves in the underside of the sloped sill to allow any water to drain into the rain-screen cavity.

It does make for a really labour-intensive and involved installation though. Multiply all those pieces and layers by the number of windows in a house and it adds significantly to the task. Is there a huge advantage to having the windows there as opposed to mounted on the sheathing?

Thanks all for the replies

newtonsapple:

Q: "what is the advantage of wraping the pan flashing over the interior side of the 2x?"

A: Do you mean the interior, vertical side of the 2x the window is upon? I didn't intend to depict the flashing wrapping down over that. Just ending around where the foam starts.

edit: I see perhaps you meant in the GBA detail. Good question. Not sure. Maybe because it won't stick well to the foam and it just adds some protection.

Q: "How are you attaching the extension sill?"

A: I hadn't actually thought that through to be honest. perhaps I would extend the furring strips up higher and somehow use them to fasten...

Peter:

Your 1) is why I thought it best to slope the 2x it sits on. It seems this 2x member is in the same location, relative to the window, as the rough sill of a typical outtie window installed at the sheathing, and we are advised to slope that area, so...

2) The over insulation at the sill is a detailing issue I am not sure how to work out. I'm not really gonna stress it though.

Malcolm:

I assume the labor intensiveness you are referring to is not just the sill detail but the location of the install? The direct answer to your question about its advantages is: I don't really know, and I am not dead set on this install.

"In-betweenies" have been described as having better thermal efficiency than outies. I haven't looked extensively at the technical evidence for this. Additionally, I thought I might like the appearance of the in-betweenie as well as the added 'overhang' inherent with it.

What might trigger a prompt, "You're posting too fast, slow down."

Knows I made too many typos? Too many nonsensical posts? haha

Whatever prompts it seems quite random. I can't pinpoint any behaviour that sets it off. Just bad-tempered software?

If you don't mind the added work, and want the windows there, then why not? My own feeling is any additional protection provided by the overhang is offset by exposing more of the wall at the jambs and sill. Something outies don't do.

I believe the sloped sill is in the expectation of the actual window itself leaking. Ie: the gaskets around the glass panes failing.

As the Matt Risinger would say; there are windows that leak, and windows that are going to leak. He did a cool video on the YouTube where he used dyed water to show how windows can leak. Worth a look to give a better idea of why sloping and backsealing the window sills are good practice.

I almost want to cut the bottom window flange off, as it just seems in the way. If its properly placed on shims it doesn't seem necessary. Of course there's the whole window warranty, so I probably won't...

but the entire concept of creating free draining paths to the exterior seems complicated by the flange. Its not getting sealed anyways (should have a slight gap between it and the 2x really) and if the window is on shims doesn't seem structural...

Along Peter's line of thinking of the system here as a roof, it again seems like an element undesired (a vertical barricade).

I am thinking I would maybe caulk the extended sill to the underside of the existing window protrusion (if you call that a sill?) yet leave a slight gap behind/below this point (between it and the flange). FWIW I am not necessarily using actual wood, just mimicking the shape of a more traditional sill with nose and ears...