Too-Thin Exterior Foam Behind Brick: Request Recommendations for Re-Insulating & Air Sealing from the Interior

Summary: My home is in CZ5A near Detroit. It was completely upgraded with new windows and re-bricked about 15 years ago. Unfortunately the exterior foam is only 1 inch EPS (R3.6) with perforated foil facer (est 0.5 perm) behind the brick. Upgrading the foam is not an option. I am planning to air seal and re-insulate from the inside. All old drywall and insulation have been removed. I realize new insulation must not trap the wood sheathing between two layers of foam. I can get a grade 1 installation if I insulate myself with unfaced fiberglass batts. They should perform well enough with the two air barrier system shown in the attached figure. All eboxes and penetrations will be sealed. I prefer vapor barrier primer (0.5 perm) so the drywall can be glued to the studs. I prefer not to use cellulose.

Attachments:

- Wall layers schematic, and

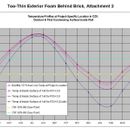

- Excel plot of temperature profiles of the first condensing surface (Wrapshield air barrier over 1×6 board sheathing) in the wall.

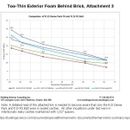

- Building Science Consulting Inc. plot of R15 fiberglass batt tested in a sealed cavity.

Observations: The months of December, January and February will always have sheathing temperatures below the 70F 35RH dew point given the R3.6 EPS foam. But note that even the plot for the code recommended R13+5 wall fails to stay above the dew point in those months.

Questions:

- Any reason not to use the Vaproshield Wrapshield SA (50 perms) and VaproBond sealant for sealing the leaky 1×6 board sheathing in each stud bay. It installs very well.

- Any reason not to use the R15 batts (which I own and are already cut & fitted) instead of switching to R11 given that both result in sheathing temperatures below the dew point in December, January and February?

All comments are appreciated. Thank you for taking the time to respond.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies