Thoughts on Larsen Truss wall idea

Hello,

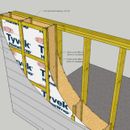

After watching the video(s) regarding interior poly as an air barrier (https://www.greenbuildingadvisor.com/blogs/dept/musings/using-interior-poly-air-barrier) I started to think about using Tyvek (or similar) for an exterior sheathing (in a non-structural role) to hold in dense pack insulation. A similar technique was used to insulate the cathedral ceiling in a demonstration home built in the videos in the previously mentioned blog link.

Attached is a graphic of my idea.

There have quite a few many homes built with a a similar wall system, but the key difference is that the exterior sheathing (non-structural) layer is just Tyvek stapled on instead of fiberboard, Agepan or plywood. The primary advantages that I see is that there is reduced material cost and the Tyvek is high perm. The primary disadvantages that I see are that the labor increases some and the only lateral loading support on the I-joists is the 1×3 furring strips (horizontal). Moreover, there could be some bulging of the Tyvek, but this should be mitigated by the horizontal furring strips and the gap should be large enough that is won’t affect the siding (1.5″).

I wanted to see if there were any other thoughts on this idea?

Other discussions on similar wall systems can be found here: https://www.greenbuildingadvisor.com/blogs/dept/musings/klingenberg-wall

(Note, the double top plate is due to the discomfort of the local framers with using a single top plate for whatever reason.)

Thanks,

Chris

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Chris,

Plenty of builders have done this. These days, most of the builders who are following this approach are using one of the new European membranes rather than Tyvek. As you predicted, the biggest problem is bulging of the membrane.

For more information on this approach, GBA readers should see these two articles:

The Klingenberg Wall

All About Larsen Trusses

The other issue that I thought of (after posting) is dealing with the window and door details, though perhaps this is less of an issue if you do the insulation install after the windows are installed and all of the flashing is done.

The horizontal strapping would help to mitigate the bulging issues I imagine.

Is there any information about how long Tyvek lasts before breaking down and falling apart? (assuming there is no contact with OSB)

Chris

Chris,

Q. "Is there any information about how long Tyvek lasts before breaking down and falling apart?"

A. According to DuPont, the manufacturer of Tyvek, "Tyvek HomeWrap and Tyvek StuccoWrap should be covered within 120 days (4 months). Tyvek CommercialWrap should be covered within 270 days (9 months)."

I am asking about how long it will last after it is covered. :) In other words, what is the expected life of Tyvek? Using this approach, the exterior insulation will fall apart if/when the Tyvek degrades.

I've never built a detail like that, but the reliance on the Tyvek to maintain the integrity of the insulation, the lack of solid nailing for the siding (the vertical furring will be bouncy) ... lead me to wonder, how much is really gained by putting the sheathing on the inside?

Chris,

Maybe I can offer a few insights since I built my own house in a similar fashion (ie, no exterior sheathing).

First of all, I should say I didn't use dense pack cellulose but rather rock-wool batts.

I'm not sure I would try dense pack with only a housewrap membrane to restrain it but maybe loose-fill would work.

If you were to go the loose-fill route, I imagine you could insulate in stages - ie, nail up your housewrap 5' at a time and blow in your insulation in lifts.

If the exterior framing is such that batts can be "friction fit" then the insulation can all be installed at once with the housewrap nailed up afterwards.

You also indicated you are wondering about how long your housewrap will last...

I wondered the same thing.

I don't worry about it because in my case I used rock-wool batts and if the Typar I used ever did fail behind the siding for some reason, I'm not sure it would really matter to much - the rock wool might sag outwards against the back of the siding slightly but so what?

A different story with cellulose though...

David makes a good point about nailing opportunities...

It's important to know how you will do your siding before the exterior frame is all covered up and insulated so that you can add a few extra sticks where they will be required.

For example, if you plan to use corner boards that are wider than the framing lumber at the corners, then adding some extra lumber as backing for the butt ends of the siding will help.

In my case I used vertical furring ripped from 1/2" plywood over Typar and screwed to the studs behind (I ripped my furring from 1/2" plywood because I decided to improvise a rainscreen at the last minute and it was as deep as I could go without screwing everything else up).

My siding is full 1" thick tamarack in a "dolly varden" profile (tough stuff) and I had no problem nailing through it to the studs.

I would also recommend choosing a type of siding that is strong and impact resistent (ie, 5/16" fiber cement or similar may be a bit too skinny).