Taping the base of house wrap over rigid foam.

I am installing house wrap over a 1″ layer of XPS. The house wrap is mostly to help air seal any joints that may have been missed or may develop in the XPS over time with expansion and contraction.

Due to the nature of the siding (ribbed steel), I am installing the foam in 8′ wide sections, with a 9′ wide sheet of house wrap, installed vertically the full height of the wall, overlapped 12″ on the side and taped (vertically).

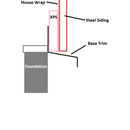

The base of the foam (and house wrap) is sitting on base trim that extends out 3″ from the foundation (underneath will get a fascia over the concrete) so any water that makes it past the siding should run down the face of the house wrap and/or XPS and drain out the base trim to the outside of foundation. See Picture:

My main question is what to do with the base of the house wrap. I have always been told not to wrap the house wrap into the building as it can force air in that gets trapped behind the wrap. I also worry a little about taping the bottom the full width to the foam, as if any moisture collects and tries to drain, I have to assume it will collect in the tape over time.

My instinct is to cut the bottom of the house wrap to be 1/2″ higher than the base of the foam, then put a 6″ wide piece of tape every couple feet to keep the base of the house wrap “stuck” to the foam, but still allow drainage to the base trim in the event of water leakage.

Does this seem logical?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

"Housewrap" is a term for a material that can act as a water control layer, air control layer or a combination of both. Some people think it's also a vapor control layer but I don't know of any housewrap products that aren't vapor open.

It sounds like you're primarily using it as an air control layer. In that case, all of the edges and transitions need to be detailed in a way that makes the air control layer continuous--for example, where it meets windows and doors, the roof, and the foundation.

In your case, it depends where the air control layer is at the floor/foundation, but wherever it is, the WRB needs to be sealed to make the transitions airtight.

The only one I can think of is this one risinger uses:

AlumaFlash Plus Peel & Stick house wrap

I wouldn’t use that in any cold climate though…

I had originally phrased my comment to include vapor retarding as a possible function but I literally couldn't think of any examples. I suppose a low-perm WRB could be a benefit in a strongly cooling-dominated climate.

Michael,

A cooling dominated climate with reservoir cladding?

Yes, you are correct, I am using this housewrap purely as a secondary "air barrier" but still allow vapor through, as my 1" foam makes a robust vapor barrier. I am also gluing (which is marginally successful with Great Stuff foam) and taping all the foam joints (Home SealR Tape) to make another air barrier.

I have started installing this as I mentioned: The bottoms are taped in about 4 locations per 8' sheet of foam, and the rest left to "flap" to allow water to drain from behind. Know that on top of this wrap, the steel siding has "closure strips" that adhere to this housewrap and will subsequently "squeeze" the house wrap to the foam when the panels are installed.

From the comments, it almost sounds like you are suggesting that put a continuous strip of tape sealing the house wrap to the foam on the outside face? Is it agreed NOT to wrap the housewrap around the foam to the inside of the building, or is that actually a better way of doing it?

I still have to detail the top: I figured I would roughly cut the wrap a little long, fold the housewrap back over itself to be shy of the edge by about 1", then tape continuously at the top of the foam.

I have a hard time determining what is best. I would hate to do something that actually funnels air into the building, as I have heard wrapping the housewrap can do, and even worse, something that traps moisture over time.

I've never tried to do what you're doing; I usually locate my air control layer at the sheathing because it makes most things easier.

1" XPS is about 1.1 perm, so it's not a vapor barrier but a semi-permeable vapor retarder.

An air contr0l layer that's open at the perimeter is not a very good air control layer, but if it's secondary as you say it's probably fine. If you want to seal the edges back to the sheathing or foundation, you can use Siga Fentrim tape--it's very sticky, airtight and vapor permeable.

Michael,

I appreciate your feedback. Yes, I realize the foam does permeate some moisture. My rationale was this is a steel building (steel girts and purlins). The foam on the outside gives me a real R5 (before stuffing the cavity) and also provides a vapor barrier that would be relatively hard to install on the inside based on the use of some of the space. I am in Missouri (zone 4 IIRC?), so we get a relatively large spectrum of weather.

My ONLY reason for using the housewrap, is I didn't like the idea of glueing and taping my XPS and then assuming that this would stay airtight over time. Glue gets old, tape gets brittle, etc. I figured the house wrap gives a pretty permanent second layer of air barrier.

Keep in mind, the house wrap will be sealed on all the other perimeters, just not the bottom. I really didn't like the idea of somehow pooling water at the bottom of my wall for the variety of reasons that can happen (condensation/screw hole leak, window leak, etc). The bottom is "relatively" sealed, as there is a closure strip that I stick to the house wrap that gets pressed firmly to the foam when the steel siding is applied. Probably not as good as tape, but perhaps a good tradeoff with drainability?

Finally, I figured if I do a good job of caulking and taping the inside to seal the bottom of the foam to my framing (see attached picture), then I can call the bottom area of house wrap more of an overlap than an air leak point.

This is all based on things I have picked up. I really have so little practical experience with this housewrap that I just want to make sure what I am doing is reasonable, and most importantly, not causing a potential for bigger problems down the road. From what I am gathering, it seems this is OK?

I was responding to your comment that, "my 1" foam makes a robust vapor barrier." Foam does shrink over time; I specify a high-quality tape such as 3M 8067 which has a long-lasting acrylic adhesive and a plastic core that can stretch if necessary.