Stick-framed equivalent to high-heel/energy truss?

Does anyone have a framing detail that shows how to create a high heel area when using traditional stick framing? I want to get lots of insulation on top of the wall’s top plate, but I don’t want to order pre-fab trusses. There is a 50-50 chance that there will be a structural ridge beam (as opposed to non-structural ridge board) in the design, in case that makes a difference (which I think it should).

How do you give yourself a good say 20″ of insulation space right to the edge of the exterior wall, when your framing members are 2×6’s or 2×8’s?

I could see the challenge being much bigger without a structural ridge beam, because then you need to faithfully “complete the triangle” at the bottom – being the ceiling joists/bottom chord – which helps to keep the wall from bowing out.

With a structural ridge beam, you could pretty much just build a knee-wall/pony wall on top of the top plate. Almost like framing another short storey that would just be all insulation?

Or with either structural or non-structural ridge, maybe you could use much longer studs, and frame your walls to be 20″ higher. Then basically build a second/lowered ceiling to mount your drywall, be the air barrier, and contain the insulation. The bottom chord of the roof triangle could be traditionally framed, and just sit 20″ higher, on the top plate of your artificially taller wall.

I want to know how you all would tackle this. Or does everyone just specify really deep-heeled pre-fab trusses?

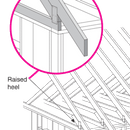

The pic is just from the Building Science people’s glossary.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Zenon,

See the illustration below. This is one way to do it. You can make it even deeper by (a) choosing deeper ceiling joists, or (b) stacking several 2x4 or 2x6 plates below the rafter bird's mouth.

.

Martin

That looks good - I like it. But only for the full-structural ridge beam option, right? Because in your pic, there is NO structural joint between ceiling joist and rafter. So the ceiling joists cannot be properly fastened to tie the rafters together to resist bowing out.

However, if you ran the ceiling joists all the way out to the ends of the rafters, you could make the connection. Then you could use a bunch of blocking instead of the rim joist in your pic. That would make it possible to put the blocking outside of the plane of the inside wall, for lower thermal bridging and more insulation packed right up to the edge. I wonder if they would allow that. Does a rim joist add much to the structure? Because the blocking would become non-bearing and the rafters would only be sitting on a series of joists.

Maybe I'll push for a structural ridge beam. It seems better in my mind.

16" or larger TJIs work fine for rafters when used with a structural ridge.

If needed you can tie the rafters to the ceiling joists with pieces of 2 x 4, OSB or plywood nailed to the sides of both: check with your inspections dept., they may require an engineer's letter to spec dimensions and nailing pattern.

Your alternative of running the joists long is exactly how it used to be commonly done hereabouts eighty or so years ago and it worked great. The ceiling joists were usually 2 x 6 run about 18" past the plate, 2 x 6 rafters were fully seat cut to sit directly on top of the joist and toenailed in. At 8/12 or 10/12 pitch this gives you an awesome amount of insulation space over the plate. Again, you may need side nailed plates and cantilever engineering to satisfy inspections.

As always, be careful of air barrier continuity whichever path you take.

Thank you gentlemen! That's definitely some helpful insight. I'm happy to see that it's possible to stick-frame and leave generous insulation space (without too much fuss).

This will definitely go on the list of stuff to run past our engineer (although I like to be well informed before taking to him $$). I have a feeling it will flummox the Town's building department, since it doesn't seem to be addressed in the Code here. The code is happy to have crummy insulation details, it seems.

Did you get this built Zenon? Curious what you did and how it went. Contemplating this question myself right now only mine is a little unique in that it is an addition so I won't have a structural ridge for maybe a year as I'm doing it in phases…

Tony - nope, not yet. You may beat me to it! In which case, please share what you did and how it went!

Will do! Here's what I'm planning, though plans don't always work out!

Zenon or Tony, if you are still getting alerts, can you update on which method you finally used that was approved ?

I worry that the amount of torque on anything attached as Tony shows would be a bad idea. Roof weight would just push any form of stub wall outwards. If the tops of the stub walls could be tied together with 2x4 running all the way across to the stub wall on the opposite side, essentially a second set of joists above the attic floor even if spaced only every 4', that would solve the torque issue just as rafter ties would.

I am researching this same issue for the REMOTE approach of all exterior insulation, but the REMOTE manual only shows trusses for high insulation depths.

Kirk Ellis

Kirk,

Apart from the various alternatives you might get an engineer to design, there is only one code approved way of dealing with the horizontal forces stick-framed roofs without ridge beams exert on exterior walls. That is to directly fasten rafter ties to each opposing roof rafters. The ties have to be in the bottom 1/3rd of the rafter span. They can be in an attic, or form the framing for the attic floor.

If you include a structural ridge beam there are no horizontal forces and you can build knee-walls of any depth you like.

With a full attic, just as with trusses, you can also increase the insulation at the eaves by adding trays or bulkheads around the perimeter of the rooms below.

Thanks, Malcolm.

Rafter ties sitting above the attic floor are certainly a traditional solution that code and inspectors should accept.

I am wondering about other solutions that might allow for future attic conversion into living space. Having rafter ties running across the attic sitting a few feet above the attic floor would eliminate that future. So would a central bearing wall acting as a roof ridge. A structural ridge beam big enough to carry 100 lb snow loads and 2000 lbs plf for long spans is also expensive, but possible. What about a 24" upright fitted into a birds mouth cut into the rafter and running down to a horizontal 2x4 running out to the rafter tail, then gusseted on both sides with 1/2" ply ? Would that be enough to convert the horizontal forces downward as long as collar ties held the rafter together at a non-structural ridge ? Or does none of this work without a structural ridge or rafter ties, period ?

I don't see how trays or bulkheads out under the eaves would solve the problem of shallow depth for attic floor insulation when trying to keep all insulation above the attic floor and the ceiling joist bays open. Insulation trays inside the building defeats the purpose of REMOTE keeping all insulation outside the VB and sheathing. I am trying to see if REMOTE can be done by building a flat box with structural sheathing and VB on walls and above ceiling joists, then building a roof above with 24" height all the way out to the walls for blown in attic insulation. With the future possibility of building another box under the roof but not supporting the roof.

Yes, a central bearing wall would work - as would a combination of beams and bearing walls if that was less expensive, simpler, or worked better with future plans in the attic. Anything that deals with the vertical forces at the ridge works, as they are what translate into the horizontal ones if they aren't supported.

I'm sorry, I'm having trouble visualizing what your second suggestion is, so can't usefully comment on it.

Is this pic clear ?

Something like that could work depending on how it is detailed. It is still working on the same principle as rafter ties. It isn't an effective moment connection, so the plywood gussets won't stop the ridge from trying to push down. They just connect the rafters to the attic floor through whatever framing you have on the subfloor. it would need to be engineered - and an engineer would have fits working out the detailing and hardware for the connections it requires.

As a general rule of thumb, if you haven't seen a common framing condition dealt with in a way you are suggesting, it's probably safe to say it's because it is a lot more complex or expensive than the alternatives.

I would use normal constriction but with a tall wall then build down for the ceiling structure. Give full use of the attic and avoids complicated construction details. Another approach might be to use a tall wall and hang the ceiling joist from a ledger hung lower than the top plate of the wall.

Jonathon,

Hanging the attic floor from ledger boards sounds easy, but would add a lot of expense for joist hangers and long lag bolts. The loads on lag bolts into 2x4 walls might limit room widths as well. It would be simpler to just add a jack stud under each joist so one supported the joist and the other runs all the way to the double top plate under the rafters. The second stud would cost less than the ledger boards, lag bolts and joist hangers. Especially since in the REMOTE system the stud bays will be uninsulated, and doubling the stud widths wouldn't affect insulation whole-wall R-value. Code allows load bearing 2x4 walls to be 10' max, though, so getting 9' ceiling below the joists plus 2x10" joist height wouldn't leave much depth for attic insulation at all. If code would allow 12' tall 2x4 load bearing walls, doubling every stud in those exterior LB walls would be an easy solution. Then the attic floor would be 2' below the top plates where the rafters attach.

If a 5.25" x 24" or 7"x18" LVL ridge beam would allow knee walls without issue, as Malcolm said above, that is sounding simplest of all. That ridge beam solution prices out to only $2K which is less than I was expecting.

If you are looking for a 1 1/2 story type setup, it is very hard to air seal this intersection properly. Either or both your celing joist or rafter tails end up poking through the air barrier, about the only way to seal that up is with spray foam. With spray foam you already get pretty high R/inch, so the height is not as important.

If you have overhangs, the one way to get more height is to extend the celing joist past the wall and tie your celing joist rafter together past the wall. You can then build a mini wall at the base above the wall there to support the vertical loads. Depending on the roof slope of the roof and overhang, this should give you a lot more room for insulation.

Overall, for 1 1/2 story, a structural ridge is the way to go. With 18" LVL you can span around 30'. If you do corbels on the inside to support the LVL, you can reduce the effective span get a couple of extra feet.

Yes, it does look more and more like a structural ridge is a necessity if I want to be able to wrap the walls and over the attic floor with continuous WRB. You are right that extending the ceiling joists out beyond the walls just to get insulation depth above the walls would make continuous WRB tough.

Even with a structural ridge, wrapping the WRB from the walls up and over a knee wall and back down onto the attic floor seems problematical. Not a problem to airseal, but because that kneewall -- or what would really be a parapet wall thinking of the attic floor as a flat roof -- would be empty of insulation. Filling it with insulation to eliminate a void in the middle of the roof-wall intersection I am worried about would mean an insulated parapet wall with VB on both sides, which is not good. It seems the only "clean" WRB wrap comes with a knee/parapet wall simply tacked on after wrapping the entire first floor platform. Without intersecting interior partition walls, that parapet wall would never stand up to the weight of the roof and wind pushing the roof around. Since the attic would be only a "future" option, knowing where to put those partition walls would be a guess. Maybe turning the triangle from rafter tail to LB wall into a gusseted truss below the rafter is still an option to avoid the knee wall.

If you want well sealed energy efficient 1 1/2 story, insulate the roof. Trying to get the air barrier through all those transitions is impossible.

Spec a roof with deep I joists, vented with baffles and batts. Air barrier is the outside sheathing on the walls, wraps over the top plate and up along the underside of the rafters. If you want super high R value, layer of rigid on the inside.

With a structural ridge, no penetrations needed either at the base or higher up for collar ties. Simple continuous air barrier.

Insulating the roof is more surface area than flat ceiling, but less than floor-knee wall-mini attic.

For insulation, there is no need to get caught up in PERSIST or REMOTE or any other "theme". Pick the insulation and air sealing setup that works for the specific application. The roof of my home has in different section: exterior rigid+batts , sprayfoam+batts, interior rigid with batts vented. This was because each setup worked the best for that section.

I had almost forgotten about I Joists as rafters. I had planned on using 16" I Joists with 14" of R-60 Rockwool batts and 2" vent baffle at one point when I planned cathedral ceilings. But ... high ceilings are just like conditioned attics in that you are doubling the volume of air in the house that must be heated and cooled. That is in additional to all the extra materials in the build. A 40x60 single story house that includes a 2 car garage has only 1900 sf of attic floor to insulate because the space over the garage doesn't need insulating. If it has a 12/12 roof that is insulated, then the ceiling of the garage also needs to be insulated to create a conditioned attic, so the total sf of insulation is 2400 x 1.5 + 500 = 4100 sf. That is a lot more insulation and it is all more expensive insulation than blown in attic floor insulation.

The air barrier wrap doesn't seem difficult to me at all. Why do you say it is ? I am suggesting building a flat roofed box with all wall and ceiling framing and sheathing, then wrap with WRB either peel n' stick or liquid WRB, then frame all roof structure above it. If I was willing to use trusses it would be simple -- just set the energy heel trusses on top of the WRB-wrapped attic floor, secure to the rim joists with hurricane clips, block between them and sheath the roof. I found this topic and re-opened it because I'd rather build with hand cut rafters than trusses and am looking for the equivalent of energy heel building with rafters. Maybe 16" I joist rafters are a solution, but quite expensive just to get the insulation depth at the heel for blown in attic insulation.

R60 is only justified with blown in insulation. Unless you are in zone 7, there is very little energy savings above an R40 roof. You can do the heat load for your house to estimate the energy savings, I would be surprised in zone 5 it would be more than 100$/year.

Attached garages need to be outside the air barrier, no need to run insulation above it. Even if the attic extends above the garage, bring the partition wall up to the attic and end the insulation there. Extra tall celings in the garage are great for storage down the road.

With 40' wide house with gabled roof 12/12 roof, your roof length is 56'.

With a 1 1/2 story knee wall at 6' in, your insulation length:

-6'+6'+3'+24'+3'+6'+6' = 54'. You are not saving anything except creating a complicated air barrier. The are behind knee walls also makes for great storage and HVAC runs, it is a shame to waste it.

Buying deep I joist for extra insulation is a very expensive way to go. Spec the I joist for the span you want, if the R value is too low, add in a layer of rigid on the inside. No problem to hang drywall even through 2.5" of rigid insulation.

Insulation, provided no SPF, is a small cost item of a house build. Go for the SIMPLEST setup both for air barrier and insulation. The headaches that saves is always for the extra bit of cost.

Robert Riversong has a method detailed on his site.

https://riversonghousewright.wordpress.com/about/11-pictures/

Thanks Greg, but the Riversong Truss is a vapor open superinsulated wall rather than REMOTE with all insulation outside the load bearing VB wrapped wall. If you tried to sheath his load bearing inner stud wall so it was a modified Larsen Truss, then wrap WRB, you would be stymied by the extended ceiling joists. You can't wrap out under the joists and around unless you want to wrap the roof as well and create a conditioned attic instead of a vented attic. That would be PERSIST rather than REMOTE. Insulation outside your wrapped roof structure means you can't use inexpensive blown-in attic insulation, you must use a board product -- or else build a second roof that would have its structure outside the conditioned envelope anyway. If the insulation is exterior on the roof, then you didn't need the attic insulation energy-heel depth anyway. R-60 Rigid foam at $5/sf, which I don't want, or rock wool board at $11/sf would be very expensive especially since a 12:12 roof has 50% more area to insulate than an attic floor $1/sf. Not to mention having to heat and cool a volume that is not living space but is just as large as the living space. To me, conditioned attics seem cost effective only with a low slope roof or if it is usable space for people or HVAC equipment.

"trying to keep all insulation above the attic floor and the ceiling joist bays open."

"I am wondering about other solutions [to rafter ties] that might allow for future attic conversion into living space. Having rafter ties running across the attic sitting a few feet above the attic floor would eliminate that future."

Putting aside why you'd want the option to convert an attic that hasn't been designed with a proper insulation strategy in mind: If you have a bunch of insulation piled on top of the ceiling joists, couldn't these ties be placed so the tops are level with the top of the loose-fill, creating the floor to the attic, providing the lateral thrust resistance, and not interrupting the path for a clean WRB transition from wall to ceiling? (given those are the parameters)