Split level basement insulation retrofit, pony wall, in Zone 4 (Victoria, BC)

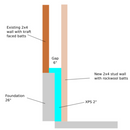

I have removed the wood paneling from a basement bedroom, which has two exterior walls. As this is a split level house, the foundation wall only extends about 26″ from the slab on one side and 40″ on the other. Currently, the walls on top of the foundation are framed with 2×4 with kraft faced fiberglass batts. I would like to have a flat wall rather than a stepped wall around the pony wall.

I have attached a diagram of a possible plan that I have put together after reading articles here and elsewhere. 2″ XPS foam from the slab, wrapping around the top of the pony wall, sealed with canned spray foam, with a 2×4 stud wall with rockwool batts. The ledge on the top of the pony wall is 4″, plus the addition spacing of the 2″ XPS results in a 6″ gap between the new stud wall and the existing wall on top of the pony wall.

A) Is this gap ok? Should it be filled with insulation? Would batts for 2×6 walls work?

B) Should there be a vapor barrier in the top half of the wall? I know the 2″ XPS would negate the need for the bottom half. If so where should the vapor barrier go in the assembly?

C) Existing kraft faced batts, should I remove or puncture the facings?

D) Would it be better to just insulate the gap area, and leave the new stud wall without insulation? This would mean that I would only have the 2″ XPS for the lower part of the wall.

Thanks!

Jay

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Jay,

Q. "Is this gap OK? Should it be filled with insulation? Would batts for 2×6 walls work?"

A. The gap probably won't lead to moisture problems, but it isn't desirable from a thermal performance perspective. (A 2x4 wall insulated with fiberglass batts is poorly insulated.)

All walls should be built with attention to airtightness, and this wall is no exception. If this were my house, I would take this opportunity to install fiberglass batts or mineral wool batts in the gap between the two framed walls, as well as between the new 2x4 studs.

Q. "Should there be a vapor barrier in the top half of the wall?"

A. Discuss this issue with your local building inspector, if any. I know that Canadian building inspectors get insistent sometimes on the need for a polyethylene vapor barrier, even in locations where building scientists say that a vapor barrier isn't necessary.

If this wall were in a Zone 4 location in the U.S., I would say (a) definitely don't install a vapor barrier like polyethylene, (b) install a smart vapor retarder like Membrain if an ignorant code official insists on it, and (c) pay attention to airtightness at every step.

Q. "I know the 2 inch XPS would negate the need for the bottom half."

A. Why are you installing XPS? Either EPS or polyiso makes more sense from an environmental perspective. For more information, see "Choosing Rigid Foam."

Q. "Existing kraft-faced batts: should I remove or puncture the facings?"

A. I would remove the kraft facing if I were you.

Q. "Would it be better to just insulate the gap area, and leave the new stud wall without insulation?"

A. As I wrote earlier, you have an opportunity to add more insulation. Batts are relatively cheap. I would insulate the gaps.

Thank you for the response Martin. I have attached an updated plan including batt insulation in the 6" space. I will remove the kraft facing from the existing insulation.

A few follow up questions.

1) would it be ok to use 2x4 (r-12) batts doubled up to fill the 6" gap? There is currently a very good sale on this material.

2) From a building science perspective what would be the correct way to ensure air tightness in my proposed assembly without an poly vapor barrier? smart membrane ? Where would the membrane be placed, between drywall and new stud wall?

3)XPS was a choice to use the least space possible to prevent moisture from condensing on the cold concrete. Most EPS foam available here is laminated (e.g durofoam R 3.75/in) would 2" still be sufficient to prevent warm air from condensing in the wall?

Thanks again

Jay,

Q. "Would it be OK to use 2x4 (R-12) batts doubled up to fill the 6-inch gap?"

A. Yes. Just do your best to make sure there aren't any insulation voids.

Q. "From a building science perspective, what would be the correct way to ensure airtightness in my proposed assembly without an poly vapor barrier?"

A. You want to caulk any obvious gaps in the wall sheathing (or any cracks leading to the outdoors) before you start insulating. Your interior air barrier is ordinary drywall. Just install the drywall in an airtight manner. In particular, pay attention to leaks at electrical boxes. Investing in airtight electrical boxes is a good idea.

Q. "XPS was a choice to use the least space possible to prevent moisture from condensing on the cold concrete."

A. Polyiso has a higher R-value per inch than XPS -- especially in climates that are relatively warm, like yours.

Q. "Most EPS foam available here is laminated (e.g durofoam R 3.75/in). Would 2 inches still be sufficient to prevent warm air from condensing in the wall?"

A. In your climate, yes.