Sound deadening

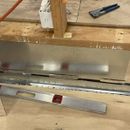

Hi all. I took a lot of time on the metal break bending metal, riveting it together, and sealing things up with mastic and foil tape to build custom hvac returns. I hated that the work I paid for was done the way it was (could see through the return boots to the basement/garage) so I figured at least I could seal up the register/return end of the system. I installed a border of the thermopan (basically foil faced cardboard) around the framing and on some of the smaller returns around the entire metal return box I fabricated. My thought was it would help to possibly cut down on noise and rattles. My question is should I put a patch of that sound deadening butyl mat on the back of the boxes to absorb vibrations and is it worth it to insulate the backs of the big boxes in the pictures with the cardboard. They are very sturdy and don’t appear to rattle when pounding on the studs. They’re also foamed in to seal the cavity from the basement and Im putting the cardboard between them and a strip of metal at the bottom to avoid baseboard nails to penetrate them on accident. Thanks.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

There are adhesive mass loaded vinyl (MLV) materials made to help with sound control in automotive applications that would work well here. Sticking them onto larger areas of the sides of the duct away from corners and bends will help to reduce the "bong/bing" sounds you get with temperature changes. You may also help to reduce airflow noise, but airflow noise is usually due to high velocity air and restrictions in the ductwork. Smooth ducts will be quieter, and there are ways to make less noisy transitions. I'm not sure how much butyl rubber or the products I mentioned earlier will help with airflow noise, but they certainly won't hurt if you want to give them a try.

Be sure to install these materials on the OUTSIDE of the ductwork. You don't want hot air blowing over them, you're likely to increase the smelliness that way.

Note that an easy way to find a good spot to put something on a resonant metal surface is to press on the surface with your knuckle while the thing you're testing is making noise. Move your knuckle around until you find the spot that reduces the noise as much as possible, then add your mass/damper/whatever to that spot. Even putting a hardware store magnet in that spot can often make a big difference. What you're doing here is messing around with the resonances in the thing you're testing. I've often done this to quiet down noisy electrical transformers in commercial buildings, where I use a small hammer to dent the metal wherever the magic "quiet spot" was.

Bill

Thanks! Hard to find the vibration point right now just because these boxes are all disconnected right now. Tapping on them to try to get a vibration doesn’t really work because they’re so sturdy haha so maybe that’s a good thing. I wish I could use some of this high temp rubbery roofing underlayment I have left over in place of those butyl mats but I’m worried it’s made of something I shouldn’t have indoors. Do you think I should also cover the back side with that foil cardboard stuff to insulate from sound? I mean the other side of the register is obviously open to air so not sure it’ll make a difference?

I would avoid using any of the rubbery sound deadening materials inside heating ducts where they will be exposed to moving hot air. There have been reports of smelly butyl rubber on dishwashers, as one example, that have been a problem for people. If you keep the materials on the outside of the ductwork, you are much less likely to stink up your house with any smelly offgassing issues.

I would not use roofing materials here. I think you'll really notice the smell of those. Roofing materials are often intentionally left somewhat gummy so that they can self heal on the roof, which is a plus for keeping out water. The downside is they tend to be messier and smellier, so I'd avoid using them indoors.

I'm not sure what you mean by "foil carboard stuff". I don't think that would do much for sound though. With sound, you are primarily either absorbing it (squishy stuff), or blocking it (heavy stuff). Most adhesive sound deadening materials are a combination of those two things, such as the realtively heavy for it's volume mass loaded vinyl (MLV) sheets. Butyl rubber tapes are similar. You might be thinking of homosote board, which is a type of fiberboard often used as a flooring underlayment to help with sound. I don't think homosote board would be a good fit for your application with ductwork here.

Bill

Bill