Soffit Venting Around Truss Panels

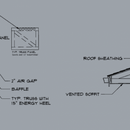

SE has spec’d truss panels between the trusses and although he did say I could drill holes in the shear material, the top chord of the truss panel is right where I want to vent and he says I can’t drill any holes there. This means I need to angle the baffle to allow the vent to come in lower than usual. Does anyone know any alternative methods I can incorporate here?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I like to run the sheathing and outsulation to the underneath of the roof sheathing for conditioned attics, and -2" for ventilated attics. The baffles extend about 6', so I don't drill holes on the outsulation and sheathing, as I feel the 2" baffles are doing well the ventilating job.

I hope the insulator is careful about not blowing cellulose inside the baffle space... all they need to do is get close and not blow the insulation from 40' away.

I also frame the soffit after the wall sheathing and outsulation is installed. To me, it's about continuing consistency in the wall assembly.

This is a product we use regularly in the application you described. You can't even see it once it's installed, it's made by DCI Products. For those in WUI areas (wildland urban interface) this vent is on the roof, as opposed to in the eave, and thus eliminates the need for Vulcan type soffit vents. That being said, the smart vent is only appropriate if you are closing in your eaves with a soffit. Use a standard ridge vent at the roof peak.

Coopers, that product will solve the problem if the SE approves the holes in the roof sheathing. I am doing a solar shingle roof, though. Have you had any problems with warranty issues or shingle insulation details? The website appears to only have a couple low quality post installation pics with asphalt shingles. Also, I can't extend the attic insulation past the shear panel so the vent would have to be one of their "mid-roof" types.

The slot in the roof sheathing is typically 6" up from the drip edge. The shear diaphragm of the roof stops at the truss blocking panels, the overhang is there for aesthetics and water management. Assuming your blocking panels need sheathing, as shown in your second picture, you could drill holes in the sheathing as shown and provide a baffle on the inside of the panel at the underneath of the roof sheathing to maintain a channel for ventilation. If your blocking panels do not require sheathing, you could apply house-wrap on the interior of the panels to keep the insulation out of the soffit and integrate the ventilation channel into that, (the house-wrap rolls up the face of the panel and attaches to 2x2's as Malcolm describes).

As for warranty or shingle installation issues, if the product is installed correctly and the roof underlayment is layered correctly, including a metal drip edge, there should be no issues. As I mentioned, the transition at the eave is subtle, you can't tell the vent product is even on the roof.

olmedo88,

Fasten a 2"x2" to each truss inside the shear panels and use house-wrap, OSB, or foam to make a vertical baffle, leaving a 2" gap at the top.

A bit of an aside: When I've had these spec-ed by an engineer, the panels were built like small framed walls, not with the 2"x4"s on edge. That makes them a lot easier to build, and secure to the trusses.

Yeah, I've seen that detail before. Any reason why you would choose that over the angled baffle? Seems like they both require a minor reduction in insulation. Interesting on the "wall framed" panels. Here is what the SE spec'd.

olmedo88,

The angled baffle will work, but is a bit fiddly where it meets the shear-panel, which on the interior has differing depths at the perimeter and the center.

I'd cut those panels about 1/8" small and install them as you stand the trusses. I've made the mistake of trying to fit them afterwards and it was a lot more difficult. Would sure be a lot easier if the panel could just be secured with a nail gun.

Engineer wants 8 A35's for each panel. It will be a pain in the rear for sure. I wish I could do it all with a gun. Might be time to invest in one of those TECO guns. You make a good point on the depth differences between the framing part of the truss panel and the sheathing part.

olmedo88,

Ah well - at least you know the trusses aren't going anywhere. I sometimes curse engineers when I'm nailing off shear-walls, but when the house is finished it's pretty reassuring to know they are there.

Talking about this one, right?

https://www.jlconline.com/how-to/framing/ventilation-vs-eaves-blocking-in-seismic-zones_o