Soffit vent with spaced boards and hardware cloth

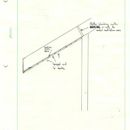

I’m figuring out how I want to vent sloped soffits under a shed roof. I’m considering stapling galvanized hardware cloth across the bottoms of the rafter tails, and then installing 1x boards perpendicular to the rafter tails spaced to allow ventilation. I’ve drawn my idea (not to scale.)

The rafters have v-cut blocking at the exterior wall. The v-cuts are the limiting factor for the ventilation area, so the soffits need to be fairly open to airflow.

I have a couple questions:

A: Does this seem like a good idea?

B: Aside from aesthetics and airflow, what else would you consider in setting the board spacing. (Smaller than an squirrel or bat so they can’t reach the hardware cloth?)

C: In this semi-protected location, will the galvanized cloth last?

D: Would 8 mesh (1/8″ spacing) galvanized 27 gauge welded keep out critters? I know it’s enough to stop bees and wasps.

E: Any alternative ideas that won’t break the bank?

Thanks!

–John

Rochester, NY

Zone 5

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I think it would work, and don't see why the hardware cloth wouldn't last long term.

John,

Unless the soffits are horizontal, I usually dispense with them altogether and locate the venting in the blocks, leaving the rafter tails exposed.

When I do clad soffits I find it a lot easier, and the results more predictable, to run the boards from the fascia to the wall. You could still use your spaced-boards if you wanted to, or space every few boards as the ventilation requirements would probably allow.

Hi Malcolm,

I like exposed tails, but I've got an i-joist roof, so I lost that detail.

How do you support the soffit boards if you're running them parallel to the rafters?

--John

John,

I run a 2"x4" along the wall and attach the soffits to it and the rough fascia. A long run of soffit boards parallel to the fascia requires two workers and is very difficult to maintain in a straight line.

Here is a soffit I installed on a recent project which uses a similar idea to what you are proposing. The venting is perforated metal stock installed every few boards. it could also have been installed to follow the roof slope.