Sloped perimeter insulation for drainage plane at bottom plate/wall intersection in persist wall

I am in the process of designing a wall with thick exterior rigid insulation with “innie” windows and the drainage plane at the sheathing behind the foam.

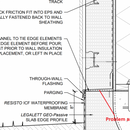

The one area that I am concerned about is the spot where the bottom plate/wall sheathing meet the concrete/foundation insulation. Most articles I have found call for Z flashing from the WRB/Sheathing to down the outside of the foundation perimeter insulation. The problem I see with this is that the foundation foam is often described as being cut flush to the top of the concrete, which effectively means that the assembly will not have a sloped drainage plane that drains water away from the wall sheathing/plate. I see the bottom plate as a vulnerable area for water to sit. Ideally I would have the foundation insulation cut short of the concrete, but I will not have that option as I plan to use a EPS raft slab product where the foam is also the concrete form.

I always see it mentioned in water management techniques to add a sloped sill (often in the form of a clapboard) as a way to drain away any water that gets behind windows. Would it be a necessary or possible to do the same here in this case?

I have been trying to think of a strategy to do so, but see problems with the wall insulation creating an area of compression on the foundation insulation. In my case, I plan on having 8 inches of rigid foam, which is a long distance to create a drainage plane. I suppose I could always install the wall rigid insulation 1/2 an inch higher (with shims), which would give space to install metal flashing that is sloped, but that also creates a long area around the house that is no longer insulated.

I have attached an image that shows the area I am concerned with

Any suggestions?

Thanks!!

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Chris,

Why don't you cut a slope into the foundation foam after the slab is poured, then sit the flashing on it?

I also see you have the flashing covering the bottom of your rain-screen cavity. Maybe that's not a big deal with a Persist wall assembly, but it does mean your rain-screen gap isn't vented.

I'd spend a bit of time on that intersection at the bottom of the cavity. That's a lot of foam waiting for insects to lunch on. Keeping them out for me would be a big priority.

Hi Malcolm,

Thanks for the reply. I am thinking your suggesting of cutting the foam may be the best option, now to rig up a large hot wire cutter..

Thanks for the advice about the ground critters. I will make sure to pay extra attention to creating a vented barrier.

I'd say either cut the insulation as Malcolm suggests, or put a piece of beveled insulation on top of the foundation insulation. I'm trying to think of an easy way to cut foam in a bevel or something that comes in that shape and I'm drawing a blank.

Going by your idea of using a piece of beveled foam, I found a youtuber who made a DIY hot wire cutter. Not sure how safe it is though. https://youtu.be/goQLCvKxOEs?t=46

Hot wire cutters work very well, and don't leave you with mounds of foam dust waste.