Insulating Slab at Garage Door

2 questions. Zone 8. My ICF foundation wall will have 8″ of rigid foam on the outside, and my slab will be floating inside the ICFs. That has to change a bit when I get to the garage door opening. If I stop all the outside foam, including that of the ICF, 4″ short and pour a concrete approach apron, smack against the concrete in the ICF, I could drive right over the top of the ICF, inner foam and all, right to the slab. The inner ICF foam will eventually compress, look gross, and fill w/ debris, but at least most of the slab edge would be somewhat insulated. Q1: Does anyone have any details for insulating there, or should I just bite the bullet, run the slab over the ICFs, and accept the thermal bridging? (2) Too, should the PEX in the slab be held back an extra 18″ to reduce the chance of it freezing? I don’t think the boiler will be circulating water through the floor all that often, so I am concerned about water sitting too long at the garage doors. Water temps, via Siegenthaler’s “Mod Hyd Heat” book (if I did the calcs right) show a water temp of about 82 F. Other calcs show 1.6 btu/hr/sf heat loss, about 6 btu/hr/sf at design temp. Thanks for any suggestions. john. Oh, yah. The Ferrari is 4×4, w/ studded tires and a trailer hitch (to pull my skid steer).

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

John,

Do you plan to heat your garage all winter?

Whatever detail you come up with at the slab edge, you're going to have a bit of a thermal bridge. Not to mention the garage door, which is one big thermal disaster.

I think your PEX loop should be filled with an antifreeze solution.

You should lower the level of the foam on the inside of the ICF wall by 1.5 inch. That creates a slot where you can drop in (or glue in) a ripped oak 2x6.

I think your Ferrari in the detail is a knock-off... I didn't see the yellow logo.

Martin:

Do you plan to heat your garage all winter? ** Yes.

Not to mention the garage door, which is one big thermal disaster. •• I know. The dealer said R17, but acknowledges that it will be "less" once you consider leakage. WAY less.

I think your PEX loop should be filled with an antifreeze solution. •• I am wavering on antifreeze, due to its reduced heat capacity. Maybe that is an inefficiency I am just going to have to live with.

That creates a slot where you can drop in (or glue in) a ripped oak 2x6. ** I looked at a foam filled, plywood box there, but a quick calc showed that the weight of the car will kill the foam. I'd have to have the wood catch the concrete on both sides. Hmmm. I'll play with this idea; it would help. Thanks for the thoughts.

Armando: I had the logo deleted. I don't like to brag.

Another thought is too abandon the radiant floor heat in the garage and install a small Toyo stove, keeping the temp about 40F. That may be the simplest, and avoids freezing floors.

Energy-Edge is perfect for this and we recently used it under the doors on an ICF house and under the 40'x10' R-16 insulated door for a hangar for construction of experimental aircraft which also had radiant floor heat. it's a rectangular vinyl extrusion filled with foam about 8" tall and 2 1/2" wide that makes a thermal break at this location. In an ICF house it gives you something solid to seal the underside of the door sill to. In a garage it gives you that thermal break you need under the garage door.

https://www.greenbuildingadvisor.com/blogs/dept/green-building-blog/energy-edge-slab-insulation-system

Michael,

Would you be willing to do another post about how well the Energy-Edge is performing at the insulated overhead doors?

Thanks,

Marc

Michael: Thanks! I checked out the link, and if I am visualizing this correctly I will be driving over a piece of PVC that is support by foam. (1) Is that working in garage doorways? It seems like the foam would "creep" eventually. Maybe I am not seeing this correctly. (2) Is the PVC going to survive a few days of 50 below and many more of 30 and 40 below, year after year? Thanks. I will try to contact the company directly, too. john

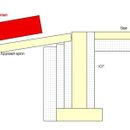

I think I solved this while skiing. I'll stop the whole ICF 4" short, lay down a strip of 2" thick by 8" wide, 40 psi EPS (60 psi if I can get a piece up here) on top of the concrete in the ICF, and use Martin's idea of a 2" x 8" oak plank on top of that, both secured to the ICF w/ anchor bolts. The slab would then be poured right up to the oak/EPS, over the top of the inner foam on the ICF. The 40 psi EPS should have less than 15 psi on it, keeping it within its 1" deformation range. I am not worried about the 2 1/4" where the slab will stick over the inner foam of the ICF; no car or light truck is going to sheer it off. If only there were garage doors that were well insulated and tight....

John,

I am intrigued by the solution you describe here with the oak insert. Would you be willing to post again on how well this is working for you?

Thanks,

Marc

Well, it is a tad later now, but I've been busy.... fishing, etc. I just ran my tweaked-yet-45-more-times idea past an engineer and he had a few suggestions. Between the two of us, here a cross-section of my garage foundation wall and how it will get mangled. We've been driving over the 12" wide x 15 psi foam for 4 yrs now, and, yes, it is a bit deformed. However, what is deformed will be cut out anyway to install the AWW 2x6. I will try to remember to get back here in a few years and post how it worked... or not. If anyone wants to check in, I am at juliet oscar lima india november alpha kilo at gci dot net.

How is this working out so far?