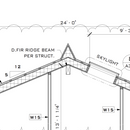

SIP roof detail & cross ventilation

Hello,

I’m in need of some advice on a new build located in zone 5 climate (pacific northwest)

I’ve attached the detail for reference. And a picture of the roof detail and ridge transition.

So my first issue is the envelope engineer mentioned he wanted the 2×4 pt running lengthwise with the roof slope. So I made the adjustment; but ran it into the ridge cap (pictured) completely blocking the cross ventilation. Not too worry; we can pull out metal panels off that ridge cap and cut it out as a whole.

I’ve read on here you’re suppose to seal all joints on the exterior as well. Well that didn’t happen.

The roof has 3 splines on either side ran vertically towards the ridge. The sip ridge itself is where the 2 massive panels meet which I just filled with spray foam.

Once I cut the ridge cap off; what will be the best practice?

Should I cut the synthetic underlayment a foot on either side of the ridge and run siga tape along that seam of where the 2 sip roof panels meet – then run a new piece of synthetic underlayment over the ridge and install the pressure treated to meat at the ridge giving that necessary cross ventilation? Or should I just run a strip of VP100 at the ridge where the sips meet overlapping the synthetic underlayment incase moisture started to build up in there that needs to be released?

The ridge cap you see pictured is just framed. More of a decorative piece to match the other 24/12 roof transition.

I also didn’t seal all the seams on the exterior of this roof section; just ran the 2 beads of caulking on either side of the splines to the sip.

What is the best way to untangle this and prevent damage?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies