Sheer Wall Nailing Error

Hello All,

I need some feedback on a shear wall question.

The framing crew had missed some nails on the top edge of the OSB. I need to wrap tape over the top for air barrier. The inspector agreed to accept pictures of the nail patterns. I noticed a few large gaps and went to buy nails to hammer in to get the correct edge nailing pattern.

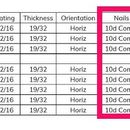

The problem is that in the structural drawings that I looked at show a 10d Comm (common) nail – 4 inch at edge and 12 in field (see atch’d table). I pulled a box off of the shelf. Then, before my purchase, I compared the box of nails to one in my pocket that came out of the sheathing. I attached the image of the two nails to this post, but let’s just say the installed nails seam significantly smaller in all dimensions.

I can image that a suggested remedy is going to be that the framer goes around and adds the correct nails between those that are in place.

I do have install rain screen battens over the 2″ rigid insulation and back into the studs. Seems like all these extra nail heads could cause a head ache. I don’t know that pulling all those incorrect nails is 1) a reasonable request or 2) can be accomplished without causing structural integrity issues with the OSB. Would doubled nails be a big concern?

Any recommendations?

Before I call the GC on this, I’d appreciate any and all feedback.

Thanks all.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Three ways that nails in sheathing can fail: the nail pulls out of the framing, the the head pulls off the shank, or the head punches through the sheathing

Rink shanks hold much better than smooth shanks, so as long as you have adequate penetration, there is a good chance that nail length isn't a major issue.

Heads rarely pull off the shank. I'm sure it happens, and assuming the metal qualities are the same, a larger shank and thicker head will stay together better than a smaller shank and thinner head.

I believe the most common mode of failure is nail heads punching through the sheathing. To counter that, you need the correctly sized head and the head needs to be driven to the correct depth.

The danger of adding too many nails isn't just the risk of hitting the nail heads with subsequent wall layers, but that too many nails close together weakens the sheathing and especially the framing members.

The right answer is to talk with a licensed engineer, who would likely have the framer come back, carefully pull all of the nails and to install the right nails in new holes.

The good-enough answer, if you're not in a high-wind area and you don't have a lot of openings in the walls, is to add enough nails to provide a similar amount of steel as you would have had if done correctly--something like adding your new nails 12" o.c. at the perimeter and 24" o.c. in the field. But that's without knowing all of the details or taking any responsibility for what you decide to do.

idahobuild,

This is for the GC and whoever designed the shear walls to sort out. Find out what their proposed solution is and then see if you are alright with it.

Are ring shanks rated higher than common nails? [Those look like ring shanks]

I think that they are ring shank nails. The GC is checking with the framing supervisor to get the specifications on the nails that they used. The GC did mention something about the nails they used having a higher rating because they are used in an air gun; or something to that affect. I just told him that since they are a variance from the plans the engineer of record will have to approve the substitution. If the ring-shank nails aren't sufficient then the engineer said that he can come up with a retrofit.

Has anyone heard of nails being made out of 'harder' wire when manufactured for nail guns?

No, but they do have glue on them which helps them hold better. But that doesn't help with head strength or pull-through.

Galvanized nails also have more holding strength than smooth nails. The galvanized coating helps with pull-out strength. There is a YouTube video of testing with nails. Check it out.