Seasonal home floor – insulated

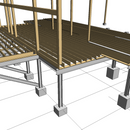

I have a project with an existing steel post and beam base structure. New wood floor framing assembly will go on top of that. This is a seasonal residence – mainly occupied in Summer, but also the swing seasons. There will be just a wood stove for heat. Home will be completely shut down / closed-up during Winter. Climate zone 6.

I want an insulated floor for comfort in Spring and Fall, but it does not have to meet energy code. I don’t think closed-cell foam is a cost-effective option here – project is on an island that can only be accessed by boat.

Underside of the floor is exposed – it’s not a crawlspace with sidewalls – needs critter protection. It can be utilitarian looking from below, but neat – you’ll see the underside when approaching the house from downhill.

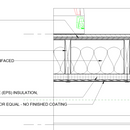

What does the collective mind think of an assembly something like this attached? I want to avoid trapping moisture. If I use EPS under the joists, and attach cement board, is that going to be permeable enough to have reasonable drying potential to the outside? Is that even desireable? Or should I not be as concerned about that and use foil-faced polyiso (and maybe 2″ of it) to make it air and vapor tight – similar to Lstiburek in BSI-115 Crawlspaces.

Will any of this restrict floor finish options above?

Builder just wants to install rigid foam between the joists and tight to the underside of the sheathing.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I like that you're air-sealing -- a sealed floor is a warm floor.

If it's open it will dry to the exterior. The vapor drive is from inside to outside. The Lstiburek crawlspace assumes an assembly that can't dry to the exterior and has vapor drive upward because the crawlspace is more humid than the interior. So you want to have some sort of vapor retarder on the interior side of the assembly and to be vapor open to the bottom. So I would put the foam against the bottom of the floor and make it foil faced.

blockitecvt,

I would insulate it as you suggest. This blog deals with these floor systems. It's worth a look, including the comments.

https://www.greenbuildingadvisor.com/article/insulating-a-wood-framed-floor-assembly

Your drawing shows an air gap between the underside of the floor and the mineral wool insulation. I would make the insulation tight against the floor (unless your underside air sealing is perfect, which will be difficult with the steel substructure).

... See section "Counterintuitive advice on air gaps" in the article Malcolm referenced.