Sealing mud sill with brick ledge

Hi everyone,

My house was recently framed and the framers sealed the sill in the typical fashion of using a foam sill gasket and then wrapping some Tyvek under the sill plate such that it runs down the concrete wall on the inside and up the framed wall on the outside.

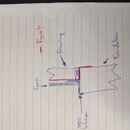

After looking at it for a while and reading all sorts of things here I decided to put in some extra effort myself to seal this intersection up a bit. I picked up 9″ rolls of SBS bitumen (https://www.resisto.ca/en/product/air-and-vapor-barrier-membrane-redzone-pro-1973/). I’m thinking of adhering this to the frame wall such that it comes down and over the foundation. By the way, there is a brick ledge here.

Is this overkill?

Also, please note that foam will be going on the walls next. The Tyvek there right now is primarily to keep the building dry as we’ve had alot of rain. The foam will be the WRB.

If this all sounds reasonable, would you just cut through the Tyvek and adhere the bitumen flashing to the sheathing, and shingle the Tyvek back over or would you just adhere the flashing to the Tyvek?

Thanks in advance for any responses.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Hi Eric.

That is not a common detail, to run the housewrap under the sill to the inside wall of the foundation, at least not in my experience.

I think you are wise to add a flashing detail like you are considering and the wall leg should probably be lapped by the housewrap, that is, unless doing so renders the purpose of the housewrap under sill detail useless--I can't say because I'm not sure what the purpose of that is (maybe a misguided air sealing detail). You may also consider a bent metal flashing. Peel-and-stick membranes typically should be protected from UV degradation and other potential damage.

I'll be curious to see if anyone else has used this housewrap detail.

Hi Brian, maybe my explanation isn't clear. It's described by Dupont in step 1 of the attachment. If I re-read it a couple of times, it looks like just may be a detail to hold the Tyvek in place more than anything else.

Ironically, on the image it shows basically what I want to do.

Hi Eric,

I guess according to the instructions, that's the way to install Tyvek. I've just never seen it done that way. As Akos says below, it's not doing any harm and what you are planning to do to flash the wall-to-brick ledge is the right way to go.

I'd bet Eric is in Canada? Dupont released lots of information on detailing their WRBs as air-barriers, and for a while builders (led by a popular TV personality Mike Holmes) were wrapping the Tyvek around rim-joists and over top-plates to integrate it with the interior 6 mil poly.

I haven't seen it done that way in about a decade. Most builders now seal that intersection on either the outside or the inside depending on where the air-barrier is.

That's interesting Malcolm. In slab-on-grade construction, I've seen lot's of builders bring the sub-slab poly under the sill plate and up onto the wall sheathing to be lapped by the WRB, but I haven't seen this before.

Your idea is the proper way to go, it will make a big difference on how tight the sill to foundation connection is (foam gaskets can leak a lot of air).

Yes you need to cut through the Tyvek install the peel and stick behind it, then lap the house wrap over it. You want to avoid reverse laps, always shingle drainage layers.

The Tyvek under the sill is not doing much, nothing wrong with leaving it there.

Deleted

Thanks everyone. Yes I am in Canada...Ottawa to be specific and our inspection office made a point of drawing a red line under the sill plate and wrapped up around the top plates to tie into the vapour barrier to show this detailing too.