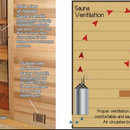

Sauna Ventilation

Good ventilation in a sauna is critical for a number of reasons including maintaining safe CO2 levels, exhausting VOCs and clearing out humidity after a sauna session to reduce mold and bacteria growth. The recommended rate is 6 ACH.

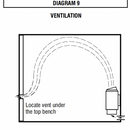

Traditional ventilation is via convection with a supply vent at the floor (or a 4″ gap at the bottom of the door) and an exhaust vent at the top of an opposite wall or ceiling. So long as there is not too much static pressure this works moderately well. A newer option is to have a powered exhaust vent below the benches and then place the fresh air supply above the heater on the opposite wall. This works better both in terms of maintaining low CO2 levels for bathers and maintaining less of a temp difference from head to toe.

In North America it has become popular to have a fresh air supply vent at the floor and then a convection exhaust vent below the benches (typically this vent is about 2′ above the floor though may be as high as 4′ (in a 7-8′ high sauna).

I look at this and have two immediate thoughts; 1) There is nothing to induce adequate airflow out of the exhaust and 2) even if there is airflow then the bulk of fresh cold air will simply flow directly across the floor and up to the vent without benefiting bathers 7′ above.

Am I missing something? Is there a practical way that this can work without a mechanical blower?

Thanks,

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

IMO, the amount of airflow without a mechanical blower is variable and usually unknown. Once you accept using a blower, then the "newer option" is your best choice. Keep face velocity high (to promote mixing).

Your points:

1) there is 2' of stratification causing some pressure difference and so some airflow

2) air doesn't strictly follow the neat lines people imagine. Some mixing will occur.

Relying on the stack effect for ventilation is usually a bad idea, because you won't get enough ventilation on days when the temperature difference is small. But in the case of a sauna, you always have a big temperature difference, so it might be viable. However, as Jon says, you only have about 2' of height difference driving this, so there's not much flow. If you want to get more flow, want to avoid a fan, and want to maintain those vent positions, you could add a chimney to exhaust vent. It could be located inside or outside the envelope. If outside, it would work a little better if it was insulated.

As for the air flowing in the arc shown, or directly across to the exhaust vent, I would think of it in terms of a combination of two air flows, one between the vents, but another being a convection flow loop within the space: up from the heater, down across the benches, and back to the bottom of the heater. That loop probably has more air flow than the ventilation air flow, so in fact, most of the ventilation air flow will get carried along with that big loop.

Thanks. This is an academic question. I'm interested in the physics of it. I should have made that more clear. Can these two vents generate airflow? How much? How consistently? Will cold supply air bend up in to the heater? Or dive to the floor and flow across there?

Thanks,

Yes, the two vents can generate airflow.

How much? It would be possible to calculate given the area of the vents, but not very accurately. Maybe better with engineering data on the vents. With a two foot height difference, it would be about 1/4 the air flow with an 8 foot height difference, for the same vents, if that helps.

How consistently? It would be consistent for a consistent inside to outside temperature difference, unless wind outside counteracted it. If you are in a windy location that could affect it a lot. The wind might dominate most of the time.

Will cold air bend up into the heater? Some certainly will. If the air flow convection loop due to the heater is bigger than the vent flow, pretty much all of the vent air will take that path. If if the vent flow is twice the heater flow, it will be half and half. If you are familiar with the concept of superposition, you can consider the actual air flow to be approximately the superposition of the convection loop from the heater and the flow from the inlet vent directly across to the exhaust. Superposition doesn't quite work, because it's a nonlinear system, but it gives a pretty good rough idea.

Thanks Charlie. I think the 1/4 would work for a 2' high room vs an 8' high room air flow (vents at floor and ceiling) but for an 8' high room with a supply vent at the floor the difference in a 2' high exhaust vent and 8' high exhaust vent would be much greater?

If I'm following your question correctly, you are comparing three scenarios:

A. A 2' high room with vents at the floor and ceiling.

B. An 8' high room with vents at the floor and ceiling.

C. An 8' high room with one vent at the floor and one vent 2' off the floor.

Ignoring other air leaks, and assuming the same interior and exterior temperatures, the air flow in A and C would be identical. The pressure developed by the stack effect in B would be almost exactly 4X the driving pressure in A or C, leading to and airflow somewhere between 2X and 4X the aiflow and A or C, the exact ratio depending on the characteristics of the vents, etc.

Thanks Charlie. I'm not getting how A & C would be the same. A will, I believe, have greater pressure at the exhaust vent than C? In both cases the neutral pressure plane will be halfway between the two vents? In A the exhaust vent will be at the full extent of stack effect - against the ceiling or as far away from the NPP as possible. In C the exhaust vent is no longer as far away as possible.

Or put another way, build room A and measure the exhaust airflow. As you raise the ceiling (keeping both vents where they are) the stack effect pressure at the ceiling increases, the NPP stays the same as the vents haven't changed, but the pressure at the exhaust vent does decline somewhat? My understanding is that the pressure at this vent would not remain the same as the ceiling is increased?

What role does temp stratification have? In A the temperature at the ceiling and thus the vent would presumably be 100°c. In C the temp at the ceiling would be 100°c but the temp at the vent location should be much lower, perhaps 40°c.

Thanks.

A and C really are the same. You are right that the neutral pressure plane is halfway between the vents in both cases. In both cases, the exhaust vent is 1 foot above the neutral pressure plane, so however much stack effect pressure difference you get from being one foot above that is what you get driving the exhaust. In C, the pressure all the way up at the ceiling is different from what it is at the exhaust vent, but the pressure at the exhaust vent is what drives the flow, and that is the same in both cases.

Maybe an analogy would help. Let say you have a 2' deep kiddie pool in the back yard. Actually, make it 2.31 feet deep. If you attach a pressure gauge on a stick and stick it in down to the bottom, 2.31 feet deep, you'll measure 1 psi above atmospheric pressure.

Now go to a 10 foot deep pool, and stick the pressure gauge in, just down to the same 2.31 foot depth. You'll read the same 1 psi.

The temperature that matters is the temperature of the air between the entrance and the exhaust. If you have stratification, it's roughly the average temperature between the inlet and the outlet that matters.

I should point out that flow is not proportional to pressure and that pressure in a stratified room isn't proportional to height. And that testing is more accurate than modeling.

> recommended rate is 6 ACH.

I would use 15 CFM per person.

Agree. If the room was occupied full time then 15 CFM would be good. As the room is typically only occupied 50% of the time (bathers typically spend 15 minutes in the sauna and 15 minutes out) then I think 7 or 8 CFM s/b sufficient? 6 ACH works out to about 7.5 CFM I believe.

Ideal would I think be to constantly measure CO2 levels and adjust ventilation accordingly (just as we measure temperature and adjust heat output accordingly). In a sauna there is some cost to ventilation so keeping ventilation to as little as necessary for bather comfort, enjoyment and health is good.

BTW, a sauna is typically about 2 cubic meters per person so a 4 person sauna is 8 cubic meters.

Part of what's going to drive the movement of that incoming cold air is the heater itself: notice they make note that it should be directly beneath the heater. This is driving the convective loop.

Thinking of this in simple terms of height differences (stack effect) would be ignoring the local deltas surrounding the stove.

You could ALMOST think of the stove itself as being a sort of blower 'motor'— though certainly not one that moves air as predictably or as efficiently as a mechanical blower motor.

If the incoming air were shielded from the heat of the stove, it's path would be different.

Consider if the incoming cold air were water. As water flows into the intake vent, it will evaporate and rise into the convective loop according to the energy input provided by the stove. If the entering water is largely shielded from the heat source, some will still evaporate from ambient-room energy input, but more will stay in liquid phase and will fill up the room until it spills out the other vent.

It's not a perfect analogy (I welcome others tearing it apart for inaccuracies) but I think it might give some representation.

Assuming house air at 70F 40%rh and sauna at 165f 30%rh.

House air is 0.075 lb/ft^3 sauna is 0.06lb/ft^3.

So if you have 2' height difference that gives about 0.005 in WG pressure difference (density difference * height difference).

At 8' height difference that goes up to 0.02 in WG.

Say both inlet and outlet are 5x6 grills. You get about 12CFM with 2' and 49CFM with 8'.

These are just ballpark calculations with a lot of assumptions, but at least show you the effect of register placement. Unless there is a good reason for it, I would place an adjustable vent as high as possible. If there is too much ventilation, you can always close it a bit.