roxul detail question

Hi all,

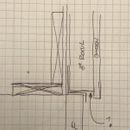

I’m using 3″ roxul as my exterior insulation on a project and have a question about how to deal with the bottom edge of it. There is a 2 1/2″ ledge created by the ICF foam, over which I’ve install metal z-flashing, and the 3″ roxul sits on top of that. See sketch and photo. The roxul extends about 1/2″ past the face of the ledge. The battens hang down past the ledge about an inch.

I will of course be installing an insect blocker (coravent siding vent material) between the battens. My question is do I need to worry about the exposed 1/2″ part of the bottom edge of the roxul? Do critters like to get into it?

Steve

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Steve,

Yes they do. Both the bottom of the insulation and the cavity need protection from rodents and insects. Unfortunately the time to do that was before the Roxul and furring were installed. It's going be a lot more difficult now.

My suggestion would be to cut off the furring flush with the Roxul and slide an L shaped piece of perforated flashing over the existing cap-flashing you have installed, that would run up the outside face of the furring an inch or so. That would also mean you didn't need the Cor-a-Vent, which will be difficult to install over that much exterior insulation.

When I encountered a similar issue with the 'pretty good house' I'm renovating for myself, I went to an Ag metal supplier and had them bend me up custom flashing that mounted to my sheathing and ended in a drip edge underneath my battens.

In your case, I would cut the furring strips flush with the Roxul and talk with the Ag metal supplier regarding a custom bent piece kind of like a D style drip edge that you can insert between the Roxul and capstrip you have on top of your rim joist. I would either pop rivet or glue the new flashing to the existing cap strip.

My custom bent pieces were about the same price as conventional flashing and made in a day.

artisanfarms,

You still want to maintain an opening at the bottom of the rain-screen cavity for ventilation, so the covering needs to be either stainless steel insect screen, or perforated stock.

I’ve only put up a few battens so far and stopped when I got thinking about this. I can easily loosen the strips that are up in order to slide L-shaped strip between the battens and the roxul. The cap flashing is coated aluminum coil stock. I’m think I should use aluminum screening to avoid dissimilar metals issue with the screening against the aluminum flashing.

Aluminum screening won't hold up, corrodes quickly and disintegrates. You need stainless mesh or perforated coil stock. I've used this before in a pinch:

https://www.homedepot.ca/product/alu-rex-basic-protection-20-ft-black-aluminum-gutter-guard/1001033236

Stainless steel fasteners are commonly used in Aluminum materials, you see it all the time in the aerospace industry. You won’t have any problem using stainless steel mesh with your aluminum flashing. You want to avoid “regular” steel mesh though, and aluminum screen doesn’t hold up over time as Akos mentioned.

If you use stainless steel mesh, I recommend 316 alloy since it’s most corrosion resistant. It’s not particularly cheap though. Perforated aluminum sheet is ok too, I’d use at least 0.03 thick here, ideally 0.04”, and probably 5052 aluminum (for better corrosion resistance).

Bill

Thanks, all. Got it under control.