Roof to wall flashing where roof ends with foam on wall help needed – its complicated

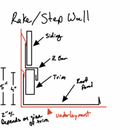

Hello and thank you all for help on this. This is a double black diamond flashing situation 🙂 My wall assembly is Blueskin vp 100. 3/4″ foam then Henry 1/4′ rainscreen then Hardie Board and batten. Where the standing seam metal roof meets wall i have a Z bar flashing 5.5″ up the wall that kicks out enough for a 2×4 to fit underneath (and wall assembly above – see detail below except the detail does not show the foam or rainscreen) after the metal roof is installed (this is described in a previous post on this site as a great way to deal with this issue and allow future work on the metal roof). This works great except where the roof ends before the wall. Both my contractor and highly experienced roofers have never dealt with this before. The roofers suggestion was to have the Hardie Board stop 2″ from the side of the roof so their metal roof could properly attach to the wall. We would have the top zbar run that full 2″ over with 2×4 later and that would be flashed. The big challenge is the sides and bottom of that cut out. I attached a few pics and a mock up with the hardie board with letters to help explain. He is recommending we get a J channel flashing (attached) made for that vertical run (A) of hardie,foam and rainscreen and then more z bar at the bottom of the cut out (B). We then caulk all the corners. He admits he is making this up. I would not be ok with this solution if it wasn’t for the blueskin and rainscreen behind all that to send whatever water gets through out the bottom. This is very complicated and ultimately needs an engineer really buts its happening now so I need help. Thanks in advance for anyone who can even understand this situation.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

To paraphrase, you plan to install a 2x4 with cap flashing and then later tuck an apron flashing under the cap flashing and out over the roofing. Is that correct? I have only done that when the trim board (in your case, the 2x4) at the wall was captured at both ends. I'm not sure there is a good way to do it while allowing for out-of-sequence work. Usually metal roofers have details figured out for that kind of thing. You might just have to install all of the flashing now and then tuck the metal roofing under the apron flashing. Or you might have to wait to install siding until the roofing has been installed.

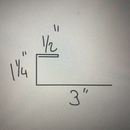

I dont think that is correct. here is a detail from the roofer except he forgot to draw the 3/4" foam and 1/4" rainscreen but that just adds 1" to the flashing.

User...372,

I've used a similar detail on the sidewalls of gables to make replacing the step-flashing on a roof with asphalt shingles easier. I'm not sure it makes as much sense with metal roofs which will outlast the siding.

It seems to me it's the 2"x4" that is causing the problem. If you eliminated that and instead of the Z-bar substituted a profile that just bumped out 1/8" you could run the typical end-wall flashing over the top of your roofing panels and up underneath the new profile flashing - which gives you the same result.

Thanks for your response. I got the roofer to abandon going 2 inches to the side of the roof to wall which was what was causing so many issues. Given my house is already 100% water tight with Blueskin and flashing he is just going straight up off the side of the roof so that crazy flashing detail is not needed. Man adding foam to the outside of the building def creates some challenges for the average contractor and roofer.