Roof build for a cold climate (Wyoming, cold and dry)

Hello,

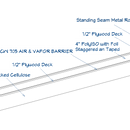

I would like to build an unvented roof for a well insulated home in a cold dry climate. Roof will be shed type without an attic. Framing will be I-Joist with dense packed blown in cellulose insulation and sealed drywall ceiling.

From my reading online I have developed the attached picture showing the roofing layers, Is this the correct build? Do I need another roofing underlayment directly under the standing seam roof?

Please let me know your thoughts.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Consider Hemp,.?

Can be cast into a void, it's R75 @ one foot thick with the most Puritan lime/shiv, you can get quite exotic with the composition, MgO slurry is 100 percent fireproof and will not conduct heat,

Conventional NRF Portland is only 200 psi, the weakest MgO starting at 10,000 psi and the best I've cast just over 80,000 psi

Hope this helps, Pray it doesn't hurt..

Thanks, but I'm not too interested in hemp.

Matt,

Wyoming has two climate zones: Zone 6 and Zone 7. Locate your climate zone on this map.

For the type of roof assembly you are planning, there are rules. You need to have to right ratio of exterior rigid foam to cellulose (so-called "fluffy insulation") in order to avoid moisture problems.

If you live in Zone 6, then at least 51% of the total R-value of the roof assembly needs to come from the rigid foam layer.

If you live in Zone 7, then at least 61% of the total R-value of the roof assembly needs to come from the rigid foam layer.

Here is a link to an article explaining these ratio rules: "Combining Exterior Rigid Foam With Fluffy Insulation."

Now let's analyze your proposed roof assembly to see if it meets the ratio rules:

R-value of your proposed rigid foam layer: R-26

R-value of your entire proposed roof assembly: R-92

Percentage of the roof's total R-value that comes from rigid foam: 28%

That proposed roof fails. So you either need (a) thicker rigid foam or (b) less cellulose.

Martin,

Thank you for your reply. This is exactly the type of response I was looking for.

To meet the rule of 51% (I am in zone 6) The exterrior thickness would get out of hand.

Would adding a 1" layer of closed cell spray foam under the roof deck be a solution?

I would rather not lower my cellulose thickness as I could not dense pack the cavity without filling it completely.

Would the plywood deck that is sandwiched between the vapor barrier and the closed cell spray foam have problems? My area of Wyoming gets 14 inches of rain per year and has an average humidity of 45%.

Matt

The rules have been established for a reason. I urge you to obey them.

To hit the 51% minimum R-value target, as I said, you have two choices: either make the exterior rigid foam thicker, or make the interior fluffy insulation thinner.

>”I would rather not lower my cellulose thickness as I could not dense pack the cavity without filling it completely.”

Perhaps you could use some thin OSB to build a “shelf” and dense pack above the shelf, thus allowing dense packing without filling the entire cavity? If you have rigid foam on top, the additional exposed rafter area wouldn’t really be a thermal bridging concern.

Bill

What is your roof span? 18" TJI's are pretty deep. If you can get away with smaller TJI's, there will be less cellulose. If they are relatively long span, you might be able to trade a heavier TJI with less depth. If there is any potential for a midspan beam, you can narrow down the TJI's dramatically.

Depending on the pitch, you might also be able to skip the foam completely and do a vented roof. With 18" to work with, you could fasten plywood or foam to the underside of the TJI flanges to create a vent space and then densepack the rest of the cavity. Vent top and bottom. This would save lots of money and still give you R-60+ for the roof.

Bill, I like the idea of building a "shelf" and packing the cellulose above that. This would give me space to run wiring and plumbing below that area.

With me being in a cold climate would I be better off using xps instead of polyiso on the roof deck?

Matt,

Since you are posting your question on a green building web site, I'm going to give you a green building answer: green builders avoid the use of XPS, because it is manufactured with a blowing agent that has a high global warming potential. For more information, see "Choosing Rigid Foam."

Either EPS or polyiso will work. If you install polyiso, just de-rate the assumed R-value to R-5 per inch to account for cold weather performance.

Since polyiso typically has an equal or higher R-value than XPS (or EPS) even at colder temps, there's no advantage to switching from polyiso.

Dana and others have suggested finding suppliers of used polyiso (or other foam boards), usually in very good condition, and extremely cheap vs. cost of new material. So you could get higher insulation, lower utility bills, at less expense! Good deal though you might have to do some work transporting all that material to your site.