Reclaimed Fiber-Faced Polyiso OK Under Vented Standing Seam?

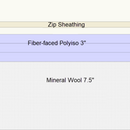

I have the chance to pick up reclaimed 3″ fiber-faced polyiso 4×8 sheets at $375 per 15, making it about 1/3 the cost of foil-faced from Lowe’s at a similar thickness (two 1.5″ sheets stacked). My plan is to use it in a “cut and cobble” mode at the top of 12″ deep rafters in a 12/12 cathedral ceiling with a 1″ air gap topped with Zip roof sheathing and standing seam roofing. (The polyiso would be sealed against a 1″ strip along the top inside edge of each rafter–see attached image.) I’d fill the rest of the rafter bay below the foam with unfaced mineral wool.

I’m in Zone-6, and yes I’m aware that I’m not meeting full code requirements, but I’m doing what I can within constraints of budget and the design of the kit we’re building. Plus my state is more forgiving for owner-builders than for contractors.

My question is whether the fiber-facing is a risk vs. foil-faced in terms of permeability. Does the fiber facing make this less like a “flash and batt” installation which would use closed-cell spray foam?

The roofers know what they’re doing, so I’m confident things will stay largely dry under the decking, and the 12/12 slope will promote both airflow upward and water runoff down to the soffit vents should anything unusual happen bulk-water-wise. Based on everything I’ve read here and elsewhere, it feels like this should work acceptably well, even if it’s not state of the art (thermal bridging and all). And I’d love to save $1,500 to apply elsewhere in the house (not to mention saving a fair amount of time installing a single layer of 3″ vs. two of 1.5″), but I don’t want to discover that I’ve missed something obvious.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

3" polyiso, aged, is about R-16 to R-18. 7.5" of mineral wool is about R-30. In climate zone 6 roofs, at least half of the total R-value needs to be in the foam layer or you risk condensation. You will have about 36% in the foam, so you are at high risk of moisture accumulation.

Fiber facing is much more permeable than foil and the foam itself is somewhat permeable, but your ratio is too far from the line for me to say that it would be safe.

If you filled the same space with mineral wool, you'd have about R-42, 90% as much R-value but totally safe from a moisture accumulation viewpoint.

Thanks Michael. That was the "obvious" thing I was looking for as I somehow missed the different ratios for roofs vs. walls in my research. The all-wool option sounds like it might be safer at that.

+1 on Micheal's suggestion.

The one thing to watch with an all fluffy cathedral ceiling install is continuous vent baffles. If you install them, they need to be permeable (ie house wrap, cardboard, fiberboard or thin unfaced foam). You don't want to use the plastic baffles.

My preference is to skip any baffles except at the soffit intake, this avoid the issues and saves a lot of cost and labor. High density batts don't suffer all the much from wind washing and if you are careful with the install the went space should stay pretty clear.

Where you want to focus your attention is the ceiling air barrier. Since you are in zone 6, you'll have to install 6 mil poly or one of the variable perm membranes under the drywall, the simplest is to detail this as the main air barrier. Make sure all seams are taped and the edges are sealed to the framing with acoustic caulk. Any electric boxes should be the flanged vapor tight ones. Try to avoid pot lights or at least minimize the count. If you do install pot lights, get the vapor barrier hats for them and tape it the ceiling vapor barrier:

https://www.electriciantalk.com/threads/vapour-barrier-around-recessed-lights.161281/

Thanks Akos. Just to confirm: Has advice on the permeability of the baffles changed in the last few years since FH recommended this approach using foil-faced iso baffles? Or is the permeable baffle issue only related to using a ceiling air barrier under the drywall (thus avoiding a fully "sealed" space that can't dry in either direction)? I've been digging into a lot of related articles here and elsewhere, and clearly finding absolute answers isn't easy, though I doubt there's any perfect answer.

https://www.finehomebuilding.com/project-guides/insulation/rigid-foam-vent-baffles#0

That is a bad idea. The foil face becomes the first condensing surface so if the foam is too thin it will be cold and you can have condensation on it.

There are people who have posted here with issues with condensation with thin plastic baffles, thin foil faced foam is not any different.

You can use foil faced foam but you need a lot of it as Michael pointed out earlier. Also not sure if any of that cut and cobble is worth the effort.

If you want to use some rigid, simpler would be to put a layer of continuous foam on the inside. This would mean hanging drywall with long screws. I have done it, not as hard as it sounds but drywallers won't do it. You can also strap out the foam with 1x4 for the drywall.