Raised floor insulation and foam-sheathed walls

Hello. I am planning to self-build a 1.5 story, 20×32 raised floor workshop in northern Delaware (zone 4). I am doing as much of the project out of wood with the exception of the finished grade level concrete piers the building will sit upon (these go down 32″ to our frost line). I have a decent downhill slope (24″) over the short (20′) width of the building. Access to the underside of the structure will be very limited given the need for it to have a low profile. The entrance door will be at or very close to grade on the uphill side so I can easily get materials and projects in and out.

It is important that the shop have a warm wood floor and the project has to be something I can build myself. I would like the building’s heating/cooling to be as efficient as possible and would like to apply best practice in building efficiency given this situation. I have been designing my project in SketchUp and bring you the following questions.

Can I insulate the raised floor and walls using the method illustrated (or attached) below?

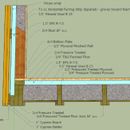

For the floor, I have 2×8 pressure treated (PT) joists 16″ o.c. with continuous 3/4″ PT plywood cleats holding up continuous 1/2″ PT plywood that will allow me to fill each joist cavity with 5.5″ mineral wool. To prevent thermal bridging, I have 1.5″ EPS board directly atop the joists flush with a building perimeter of 2×4 PT on the flat setting above the rim joists (under where the plates will be), and 3/4″ T&G Advantech will go over both to form the shop floor. The load on the floor will only be woodworking shop equipment, no heavy equipment or point loads is planned.

What could I do to improve the efficiency of this floor system? Spray foam or caulk at the joints? Any sort of air or water barrier required? Is there enough compression strength in EPS to be directly applied over the joists?

As an unpreferred alternative, I could lay 2x atop and perpendicular to the joists as sleepers on 24″ o.c. and insulate with the EPS between those, but that does not solve all my thermal bridging.

The above plan (and even the alternative) will allow me to set my joists and build everything from the top as I do not have access to the underside of the joists for attaching foam or plywood directly. Over what little space there is available under the building, I intend to put down a permeable fabric on the ground and cover that with a few inches of gravel.

For the walls, I am using plywood as my interior finish (it is a workshop after all), so from the inside out, I’ll have 1/2″ plywood over 2×4 16″o.c. framed walls filled with mineral wool (R-15), then 1.5″ EPS (R-7.5) directly applied to the studs on the exterior. That will be covered in housewrap. I am using true 1″ cypress boards and battens as my exterior finish, so those will sit on T1-11 furring strips that I’ve cross cut with a bevel to the exterior so the grooved side sits against the house wrap and allows for air and water movement. At the bottom of the exterior wall, I’ll close off the T1-11 groves with some insect screen. We have carpenter ants, termites, and all the other usual suspects here in northern DE, so I’d like them to be kept out of the structure. Does that configuration work for reducing thermal bridging, provide good insulation and a suitable surface for attaching the exterior finish? Does the fact that I have interior plywood help in creating my shear walls?

In both applications, I realize that the 1.5″ foam may be more than I need, but 3/4″ seemed not enough and 1″ doesn’t easily work with standard dimensional lumber.

Thank you for the great community here and the great resources. Appreciate any insight you can offer on my proposal.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

User 712 etc,

These types of floors close to grade are always a real pain to work on and get right.

Foam doesn't have sufficient compression strength to be placed over the joists without a subfloor underneath, it will crush. Unfortunately the place for the continuous foam is on the underside, where you don't have easy access. The solution I've used with good success is to frame the floor in sections upside-down. Once the foam and protective plywood are installed, you flip the sections over and fasten them to the beams (Or of the beams are flush, build them into the panels, with the hangers upside down).

With a couple of helpers you could probably do it in four sections, if working alone you may have to break it into more manageable sizes. it will save you a lot of time monkeying around with the cleats on each side of the joists and cutting all the plywood on the underside.

Good luck with your project.

Peter,

That looks pretty buildable. The main problem I've found is you have to be pretty precise in squaring the sections as errors get magnified when you turn them over. I'd do a section through where the panels join too. If the piers are low enough for the rims, what do the 2"x8"s bear on?

As to the gap between the subfloor and mineral - Building Science actually suggests it as a way to keep the flooring warmer. I'm not sure I buy that argument, but it certainly does no harm.

I agree that keeping rigid insulation to the same nominal dimensions as lumber saves a lot of headaches. Unless 1 1/2" EPS is a lot more expensive than 1" I'd stick with it.

Malcolm,

I've sketched up 4 10x16 sections and attached an exploded view below. Each section of 13 2x8s, 2 2x10s, 5 sheets of 1/2" PT CDX, and 5 of 1.5" EPS weighs in at around 1000lbs. Flipping each of those is going to take several friends and some frosty beverages, I'm sure. I think I could rig a ratcheting mechanism so the flipping part is more gradual and not as dangerous.

In the exploded view, I show the remaining 2x10 rims that could be added once things are upright. I can't imagine adding these later should be an issue since the joists, insulation, and plywood all sit flush to the double rim. The 2x8s attach to the double 2x10s all around the perimeter and down the middle. The rims then sit on the girders.

I'll be setting the four sections on three parallel girders. The girders might be sitting right on the post caps at the low end.

How well sealed do those joists bays have to be for that dead space not to collect moist air? I would tape the foam but do I need to caulk any of the wood to foam or wood to wood joints?

Appreciate all the input on the design. Any thoughts about the exterior foam with plywood sheathing on the interior (for finish and shear wall strength)? I'd like to not have plywood on both sides of the wall if that is possible for build and cost purposes. I'd be open to diagonal let-in 1x4 bracing if there was a shear wall concern.

Thanks for your input, Malcolm.

Peter

Deleted

Hi Malcolm,

Thanks for the reply. I'm Peter and I thought I'd corrected that on the profile.

I was hoping to avoid building it upside down in sections, but I admit I am intrigued by the challenge. I think I could build 4 10x16 +/- sections upside down with the joists, the insulation, plywood, and half of the rims and manage to get each upright and then connected.

Would the insulation detail look something like the below? I shifted the 1/2" PT and the 1-1/2" EPS to the bottom, added another 2x8 against the rim and built up the rim to double 2x10s so there's good purchase on the 6x6 post without a lot of fussy details around the post for the insulation. Is 1-1/2" EPS too much for the underfloor? I like how it with the plywood flush up against the 2x10. How about the gap with the mineral wool under the floor? Going up to 8" mineral wool is a good cost jump and I'm not sure if I'd benefit from the extra cost.

Malcolm, thanks again.

Peter

Malcolm,

Thanks for letting me know about your experience. Because the building is 20x32, it quite easy to make the change to 8 500# sections instead of 4 1000# sections and still have pretty simple construction (see below). I had considered going with four sections and sizing down the joist lumber to 2x6s, but I'm not really crazy about a potentially bouncy floor and that is only a minor weight loss.

What I do like about the use of sections is that all the 2x8s will have 1.5" EPS (R-7.5) under them and reduced thermal bridging, and with the added mineral wool, I'll have a comfortable wood floor.

Thanks for all of your insight and help.

Peter

Peter,

Cheers.

Peter,

I have a lot of respect for Malcom's experience, but I don't recommend the approach he is endorsing.

Their are a lot of problems with wood-framed buildings with floor joists close to grade. Buildability is only one of them. You need access under your joists for a variety of reasons.

Two problems no one has addressed yet:

1. You don't want a "permeable" fabric over the soil under your house. You want polyethylene or EPDM roofing or a pond liner -- in other words, a vapor barrier.

2. You really don't want a grade level entrance unless you switch to a frostwall-and-slab fundation. A grade level entrance puts the grade right against the floor joists.

You could, I suppose, locate the door threshold about 12 or 14 inches above grade, and then build a long wheelchair ramp from grade to the door threshold. But I still don't like it.

Here's my rule: Only build a crawlspace if it is high enough for a human being to access for maintenance purposes. If you don't have enough room for an adequate crawlspace, you need a slab.

Martin,

I agree entirely. A framed floor close to grade is always a second-best alternative. However, the downsides are mitigated in outbuildings which typically don't include plumbing or mechanical systems, and if you decide to build that way, the method I describe yields good results.

Q: Isn't the foam still taking on point loads in the second drawing?

Why not just place the foam on the bottom (ground facing) side of the plywood (terminates at piers rather than partially covering the top of said piers) instead of sandwiched in between?

John,

As long as the ends of the joists are supported by joist hangers, or resting on a beam or a post without any intervening foam, the second drawing shows an acceptable detail.

Martin,

I feel like I'm back stage at a rock concert getting tips from the main act! You guys are rock stars and I am humbled by you weighing in on my project. I've been reading and following your work here and in FHB for years. Thank you for taking the time to respond!

I have attached a side profile showing my grade change over the 20' width of the building. By going the route of building in sections, I've added girders (no longer flush beams) to support the floor, so the structure is a bit more off the ground than I had originally designed and discussed with Malcolm. It's a work in progress after all.

The lone post on the left will support a post for a 10x32' overhang from the main roof. From that downward slope is where I'll have the main wood shop entrance. Given your thoughts about the ramp and the grade up against the joists, I may opt to frame a 10' deep deck under that overhang to allow me to keep the building at a low profile and still accessible from grade. It would be easier to replace deck parts that floor parts if the ground contact proves problematic.

I am not planning on running plumbing to the building as my main home is 20' away. I will obviously have electric, but that will be surface mount in conduit, so no cabling buried in the floor or walls and few penetrations in or out of the structure. I don't foresee having to crawl under the floor, though it is now several inches higher than I had originally planned.

I like your idea of upping the ground cover to a pond liner under the floor. That eases several concerns. I will probably run buried perforated pipe across the high side of the slope ahead of the building to deal with any water that might one day come through this part of my yard. I would probably also tie my downspouts into such a drain.

I have intentionally kept concrete at a minimum in large part because I work with wood and that's what I know. I had labored over various designs that included a laid block foundation, closed crawlspace, slab, etc. but given the site (big trees+roots, crazy slope, distance from paved road, etc.), I settled that concrete piers were my best DIY option.

Thanks again to all of you for taking the time to respond.

Peter

John,

The load is on the pressure treated 2x10s and not on the foam at the floor edge. The 2x8 joist ends will rest on joist hangers attached to the 2x10s. Hopefully that explains the second drawing.

Thanks for checking in.

Peter

I need to clarify in my above examples that the intended rigid insulation I will use is XPS, not EPS in both the floor and wall. I confused these two in creating my drawings. Blame it on the blue color. Thanks!

Peter,

You wrote, "I need to clarify in my above examples that the intended rigid insulation I will use is XPS, not EPS in both the floor and wall."

That's too bad. EPS is more environmentally friendly than XPS, because XPS is manufactured with a blowing agent that has a high global warming potential. For more information on this issue, see "Choosing Rigid Foam."

@Martin/Peter,

Ahh yes. Joist hangers. It's coming together now. thanks

Martin/Peter,

If the space under the building is going to be open to the outside, I don't think it matters much whether you use a permeable or impermeable ground cover. My preference would be a permeable one. With impermeable ground covers, i often see water pooling on top of the cover, due to blowing rain, surface drainage and/or condensation. Ponds under your building will just breed mosquitoes.

You haven't really discussed whether this an open or closed crawl space. I am guessing that it will be open because of the PT plywood on the bottom, which is usually done to protect against critters. Regardless, it is still best to grade and rake the soil before putting down your ground cloth so that there is a smooth surface and ideally a little bit of a crown so that water flows out towards the edges. Directing the uphill surface flow away from the building is also important.

Peter Engle,

Good points. The reason I think it's worth considering a vapor-impermeable ground cover (even if the crawl space is well ventilated) is that the wood framing will be very close to the soil. Yes, I know that the lumber and plywood are pressure-treated -- but if these materials are only a few inches away from grade, I'd sleep better at night with a vapor-impermeable membrane over the soil.

A compromise would be to use a vapor-impermeable membrane on the uphill side of the crawlspace, and a vapor-permeable membrane on the downhill side of the crawlspace.

IMO, you want a membrane that is vapor impermeable and bulk water permeable (ie, some small holes).

Malcolm and Peter Engle,

Given the slope of the land under and around the shop, I'm not too worried about water pooling underneath.

I'm thinking EPDM or pond liner as was suggested and then covering that with a few inches of gravel to hold everything down and keep it tidy. On the uphill side of the slope, across the incline, I will probably run a ditch lined with fabric, filled with perforated drain pipe, and back fill with gravel with both ends of the pipe reaching daylight downhill beyond my building. In this way, any water that could wash down the incline (unlikely but worth planning for) could hit that ditch and be re-routed before it has a chance to get under the building.

Someone told me that I don't need to have pressure treated joists because they're all being encapsulated by the foam and PT plywood. I'm not comfortable skipping the pressure treated floor structure and the savings is not huge for going with the alternative. PT is cheap insurance in case of a leak.

I am not planning on closing in the space under the shop with siding, lattice, etc. When I think of "open crawlspace" I am thinking of a vented masonry crawlspace and I'm definitely not going that route. I will just have the EPDM and gravel and hopefully lots of moving air. I live near the mushroom capital of the world, so I don't need any mushrooms growing under my shop!

Thanks again.

Peter

Martin,

On the EPS vs. XPS, if I can find EPS locally, I will go with that. I have a ready supply of 1.5" 4x8 XPS 3.5 miles from my home. I read that XPS is scheduled to change to a new, more eco-friendly formula in 2020, which if I have to delay my build becomes an option. From what I have found so far, I'd have to have EPS special ordered. I'll keep hunting. Thanks again.

Peter

Peter

Peter: These folks 15 minutes north of Wilmington get in reclaimed roofing EPS & polyiso on a fairly regular basis, sometimes XPS too:

Repurposed Materials Inc

60 Walnut St, Ste. 3

Marcus Hook, PA 19061

610-485-3131

I'm not sure how often they update their online inventory- looks like they have a bunch of 2" polyiso in right now, which would be good for the walls:

https://www.repurposedmaterialsinc.com/philadelphia-inventory/

https://www.repurposedmaterialsinc.com/poly-iso-insulation/phi-insulation-2-x-4-x8-18pc-cheap-used-salvage-surplus/

$400 for 768 square feet of polyiso per bunk isn't terrible at about $17 for a 4x8 sheet, (cheaper than virgin stock 2" XPS & EPS, greener too) but I've seen it cheaper near me. They don't say how many bunks they currently have ready to go but 2" polyiso is REALLY common stuff in the reclaimed-foam world- there will always be more.They may have more than enough to do your whole project in stock right now (call). Some sheets will have damage- buy about 10% more than you need.

Polyiso is great for walls & roofs, but not suitable for ground contact.

They also have a bunch of insulated pavers suitable for ground contact (half-inch concrete on 3.5" polystyrene) at the right price, but only 240 square feet, less than half what you need, and thicker than what you're looking for.

https://www.repurposedmaterialsinc.com/insulated-pavers/phi-insulated-paver-4-x2x4-30pc/

I also like to work with wood but there are locations where concrete is clearly a better choice.

Consider today’s pressure treated lumber formulas have not been around long at all. We have no history to tell us how the new formulas will hold up in 50 or 100 years. Some of your wood will be very close to the ground consider what would be necessary to replace that wood.

My guess is the payback period for an R30 floor is over 30 years please make sure your floor will last that long.

Clearly you are planning a high performance building. In my opinion 1 ½ story building are so difficult to properly air seal the time and materials are better spent building a full 2 story building with the same number of square feet.

Do you think R22 walls make sense with an R30 floor? Normally the floors R value is about 1/2 of the walls.

Walt

Dana,

Thank you for looking into that. I was checking them out the other day. It looks like it is the luck of the draw, but I have some time before I break ground, so visiting them frequently could lead to a major savings eventually. I am shopping our local Habitat store for the same reason.

Those pavers are intriguing.

Thanks again.

Peter

Hi Walter,

Thank you for joining in. Very much appreciated.

If my building foundation lasts 50 to 100 years with the current formula of pressure treatment then that seems a good return on investment, even better if I live to see it fail! I've seen a lot of concrete and block work that failed in a decade or less and some untreated wood that looks great after 100 years in the riverbed. I have practical limitations that I have to live within now. For this reason, I am turning to GBA and other resources to help me better understand the options available so I can make an informed decision for my particular situation (in as much as the local AHJ and the laws of nature allow). Rereading this thread I can see where my course has been altered for the better, but more concrete is one place I have no desire to steer toward.

I am flattered that you consider this a high performance building. I started out my design for an uninsulated shed and things grew from there. In that time I renovated my smaller garage shop that I made some improvements to, namely mineral wool in the walls and ceiling and a raised, insulated wood floor over the concrete, and now I can heat the whole thing with a milk house heater. Those subtle improvements really made a difference and so I've invested my time in trying to learn from folks like you, Malcolm, Marty, Dana, and the rest to see how I can build smarter and possibly be a guide for others through this larger shop build.

So you have given me a lot to think about, and the question of payback for insulation is an interesting one. I am mainly using the 1.5" foam because it works alongside dimensional lumber well. I could be swayed on that, but I do know that there's a minimum thickness (1") that I need to use and an added 1/2" doesn't seem excessive. As for the mineral wool, similar idea in that I had thought I needed to fill the joist cavity with product. If I can get away with R15 in the floor and 1" foam, then I just might go that route. Floor minimums in zone 4 Delaware are R19. If I won't see savings in 30 years I should probably just go back to the bare shed design, buy a fan and sweater, and oil my tools. That's a lot to consider.

As for the height, I have deed restrictions that prevent me from doing a two story. What I am calling a 1.5 story is really a main level with 8' deep lofts (for storage) on either gable end and a 16x20 area in the center that is open to the ridge. There'll be lots of natural light from south-facing shed dormer windows that are part of the roof plan. I promise I'll start another thread when I start asking questions about foam above the sheathing, but I am interested in the difficulties of air sealing a 1.5 story.

Walter, thank you again for sharing your thoughts. As I said, you've given me a lot to think about.

Peter

There are many foam reclaimers out there, but it takes some sleuthing to figure out where they are in your local area.

Nationwide Foam ships anywhere in the US, and always has 1.5 & 2" foam stock somewhere in the US. They operate from regional depots (I think there is one in WV)- the prices are low but the shipping is a cost-adder, so the distance to the depot makes a difference. When your design is firmed up it's worth getting a quote including shipping & delivery schedule. If you have a place to store it, buying it well in advance is prudent, because inventory changes every hour,

http://www.nationwidefoam.com/

My point is that there is no question that properly installed concrete will stand the test of time. Today’s pressure treated wood formulas have no track record. So you need to say IF my foundation will last. With concrete there is no if needed.

It has been my experience that moving dirt and pouring concrete are very good value for what you get.

With a 1.5 story building in the center of the building you have a ceiling with a floor above all inside the conditioned space as you move along the joist toward a wall at some point the floor above goes away. Now you have ceiling inside the conditioned space and the top of the joist outside the conditioned space. Every joist space is a big air leak from the conditioned space to the unconditioned space at both ends. The sheer number of these gaps makes it a challenge to make a good air seal.

In my opinion if you have R10 time and money spent on a good air seal is a better investment than more insulation within limits.

You may want to consider a slab floor at grade on the low end of the building with 2 stories above and a shallow roof.

My guess is if you offer 2 drawing for approval a 2 story box with a flat roof that meets their requirements and a 2 story building with a 3 in 12 hip roof and a request for a variance you get a variance.

Walta