R60 Cathedral Cieling on Timber Frame Cabin

I have been working on the design for a small timber frame cabin I plan to build in the Catskill mountains in upstate New York, climate zone 6. I am trying to get to R49 (current code), or better, R60 on the cathedral ceiling without covering the timber rafters and T & G ceiling. One approach from Rob Myers’ 2016 series “A Timber Frame House for Cold Climate” [https://www.greenbuildingadvisor.com/article/a-timber-frame-house-for-a-cold-climate-part-3] would have me pile 10 inches of XPS on the roof and screw it down with super long and expensive screws. This approach is pricey and I’m a little leery of trying to aim a few hundred 12″ screws through all that foam.

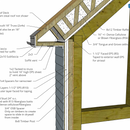

My research on GBA led me to the article “How to Build an Insulated Cathedral Ceiling” [https://www.greenbuildingadvisor.com/article/how-to-build-an-insulated-cathedral-ceiling] and the suggestion to deepen rafters by suspending the ceiling below the rafters from plywood gussets. This got me thinking maybe I could do something similar above the rafters. Since this structure would be holding up the roof with a 50 psf snow load, it would have to be stronger than the plywood gussets, so I thought I might build 18″ trusses out of 2x4s (as shown in the attached image) or use I-joists.

I’ve sketched out the assembly and it seems to me like it would work, but I’m no expert, so have at it. Beyond general thoughts on the assembly, I have a few specific questions:

1. Assuming the seams and corners of the rigid foam are properly taped and sealed, does the assembly as drawn make sense from an air sealing perspective. It seems a little weird that the roof air-barrier is inside the cavity insulation while the wall air barrier is outside the studs, but I’m still creating a tight foam shell around the entire structure. In the details I’ve seen the air barrier is created at the dry wall, but it’s tough to create a good tight air barrier with the drywall since there are big timbers in the way.

2. The timber frame structure only requires big rafters 36″ o.c. as this truss is fully supported from underneath could I set these 36″ o.c.? Maybe with 1-1/2″ T & G replacing the sheathing?

3. Truss or I-joist? If I build the trusses myself it will be a whole lot cheaper; I-joists a whole lot easier/faster. Any design/engineering reason to prefer on or the other?

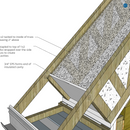

4. The second attached image shows how I could create a 2″ air gap above the dense-packed insulation on the roof. The cavities could then be filled from the top. Does this seem like a reasonable way to do this?

5. Finally, would it be worth the trouble/expense of filling the little triangle above the wall framing with some spray foam? I’m thinking that might be a good fallback for the taped seam where the roof foam meets the wall foam.

Thanks in advance for your thoughts.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

What you've created is called an "overroof." They've become popular as code insulation for roofs has become more demanding. JLC had an article about them:

https://www.jlconline.com/how-to/insulation/why-and-how-to-build-an-insulated-overroof_o

There is almost no energy cost saved between an R45 and an R60 roof. When doing simple loose fill, by all means add more. For cathedral ceilings, stick to code min.

+1 on the over roof.

No need for trusses or I-joists, you can use 2x12 purlins filled with two layers of R24 batts. Cross strap this with 2x4s on flat to form the vent channel. This is R48 but close enough.

If you want better, go with 2x6 purlins with R24, cross strap with 2x8 rafters with another layer of R24. This reduces the thermal bridging almost to the same level as continuous exterior insulation and also provides the vent channel in on shot. Higher assembly R value for about the same labor and material cost.

No need for the rigid under the roof, use a self adhered membrane over the T&G. This also lets you get the place under roof and weather tight before the over roof goes on. Make sure the peel and stick has either acrylic or butyl adhesive as these won't react with the sap and tend not to smell.

carpenter_steve,

Just to add to what DC and Akos have said. If you can find an engineer willing to design, approve and supervise site-built trusses, you will have paid much more than if you just had them manufactured.