Post-frame workshop retrofit

My goal is to create an energy-efficient woodworking shop by retrofitting an existing pole barn. The barn is the right size for my shop and is well sited on the property. I have read the articles and discussions on GBA regarding the difficulty of properly insulating and air-sealing a pole barn. However, I’d like to make use of the existing structure, even if the cost savings end up being minimal. I would like to minimize the amount of concrete and additional lumber used in the retrofit. I plan to do much of the work myself, and it will be my first time building anything larger than a garden shed.

Climate Zone: 5B (Oregon, Mt. Hood)

Existing Pole Barn:

The dimensions are 20’ wide, 40’ long, and 10’ from the ground at the highest grade elevation to the bottom of the roof trusses. Posts are 6×6 PT lumber spaced 10’ apart. I have not confirmed whether the posts are set in concrete footings. Girts are 2×6 spaced 24” o.c. The siding and roof are both exposed fastener metal sheet typical of agricultural buildings. There is no slab — the current floor is plywood (presumably over wooden sleepers), and it slopes in the long direction of the barn. The grade drops about 4 or 5 feet along its 40’ length.

Proposed Floor System:

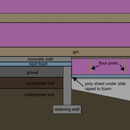

Because this is a woodworking shop, it needs a strong floor but does not need to support vehicles. However, I would like the floor to be at or close to grade at the uphill end of the shop to make it easier to move in heavy machines and materials. My understanding is that the best choice of a grade-level floor is a slab-on-grade foundation. The downhill end of the slab will, I expect, need a retaining wall to allow for soil compacting and retaining the gravel under the slab. I also plan to pour an exterior apron pad (probably sheltered by a porch roof) for easier unloading of vehicles.

For the downhill portion of the floor, I am thinking of framing out a wooden floor system over an unconditioned vented crawlspace. This would be comprised of floor joists or trusses hung from a rim joist, dense-packed cellulose between the joists/trusses, and a layer of taped rigid foam under the joists, with plywood below that as the most exterior layer. I want the comfort of a wooden floor system, and also my hope is to reduce concrete use and cost compared with extending the slab over the 4 to 5 foot drop. It might be desirable to use a framed floor throughout the building, but my requirement for a grade-level entrance at the uphill end would mean having some joists below grade: not a durable solution.

For aesthetic purposes, I would like to enclose the crawlspace with a stucco exterior as described by Christi Weber in her recent post, helical piles with vented crawlspace.

The concrete slab at the uphill end will sit atop a polyethylene vapor barrier with rigid insulation (EPS or mineral wool) below that. To maintain the air barrier and vapor barrier at the connection between the slab and the framed floor section, I’ll extend the polyethylene sheeting from under the slab to be wrapped under the floor joists and taped to the rigid insulation under joists.

Questions:

- Is there a better detailing of the connection between the two floor systems than what I described above?

- Should I be concerned about whether or not there is a concrete footing under each post?

- How do I create a thermal break between the exterior apron slab and the interior slab?

- To protect the slab from frost heaves, should I use a vertical piece of foam at the slab perimeter, or a sloping skirt of foam extending outwards and down?

- Is a 10ft span for the rim joist a concern?

- If I want to add plumbing (water and waste line) is it challenging to do this through the unheated crawlspace using an insulated chase? Is putting this through the slab much preferred?

- What issues/concerns go along with enclosing the crawlspace? Is it better to leave the crawlspace open at the end of the building and enclose only the sides?

Proposed Wall System:

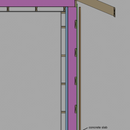

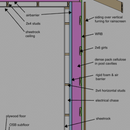

The old metal siding will be replaced with Hardie-Plank or similar cladding on top of vertical furring strips to create a rain screen. Inside of that would be a WRB. My understanding from Randy Williams’ article is that sheathing is not required because the post structure provides sheer strength (would appreciate your thoughts on this) so the WRB (such as HydroGap SA) would be attached directly to the girts. If sheathing is needed, it would go between the WRB and girts. The spaces between the girts and the cavities between the posts will be filled with dense-packed cellulose. A layer of rigid foam would go on the interior side of the posts to prevent thermal bridging. The foam could be taped to provide the air-barrier, or could be accompanied by smart vapor retarder such as Intello. Inside of the air barrier would be a horizontal framework of 2x4s to create space for electrical, and sheetrock inside of that.

Questions:

- Is sheathing needed for sheer strength in a post frame building?

- I have seen GBA posts suggesting the use of poly instead of Intello for the interior air barrier. Is that okay here? Or would a foil-faced rigid insulation layer inside of the posts provide an adequate air barrier?

- Gregory La Varda’s 8/7/24 article shows the interior horizontal furring mounted vertically. Does this provide enough space for electrical boxes if foam is behind the furring instead of compressible insulation?

Roof System:

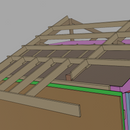

The existing roof trusses would have Intello attached to their undersides, with this air barrier taped to the wall’s interior air barrier. Beneath the air barrier would be 2×4 framing to create a gap for electrical wiring and for mounting light fixtures to the ceiling. A sheetrock ceiling would be hung below the 2×4 framing. The attic space above the Intello would be filled with cellulose. Above the roof trusses and purlins would be plywood sheathing and a metal roof. Between the roof trusses would be venting channels connecting the eves to the attic interior.

The existing roof has no eves; I plan to add rafter tails to extend the roof and create an eve. These will be supported at their upper end by a joist hanger on the lowest purlin, and at the wall by adding a girt with a bevelled edge.

Questions:

- The roof trusses do not have a raised heel. Can I remedy this by using a different insulation material in the limited space on top of the walls? Or should I just live with the reduced R-value at the tops of the walls?

Openings

I intend to install four windows along the south side of the building. The uphill end will have double doors for bringing in materials and machines. The downhill end will have a single entry door and a small porch or stoop.

- I’ll confess to being a bit overwhelmed by Joe Lstiburek’s article, “Windows Can Be A Pain.” Any tips for properly sealing/draining windows in this kind of wall assembly?

HVAC

I plan on a ductless mini split heat pump, wall mounted. I’m not planning on a ventilation system beyond the ability to open windows. The shop will be equipped with a dust collection system and an air cleaner.

- an HRV seems like overkill, and I worry about such a system getting clogged by sawdust. Supposing I use the shop for 8 hours on a winter day, will air quality suffer noticeably? Should I install an exhaust fan to pull a little air through the shop?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

My guess is if you sold and they removed the pole barn you could build a better version of your dream shop for 30-50% less money.

Seems to me you are reusing what the post frame and the roofing? The roof is old and the post frame is all wrong for your tight well insulated goal with hardy plank siding. To make your goals you end up building walls that fit inside the posts. What is the point of keeping the posts if you are paying for new walls anyway.

Walta

Thanks Walta, it had not occurred to me to sell and remove the pole barn. I am wondering if the cost savings you expect comes from that sale, or if there is another reason that it would be cheaper to build from scratch. My logic was that, compared with building a double stud wall I would be starting with a structural wall using the posts and would only be building the non structural part of the wall, and similarly that using the existing roof structure would save labor and materials there as well. I need to pay for siding, insulation, floor system either way. Is it the labor cost that you expect to be much higher for a retrofit?

I would not expect the building to sell for much but a little cash is nice and it will keep useful stuff out of the landfill.

When I read your question, it sounds to my ear like you really want a tight well insulated building and the budget is not a big issue. If I am total wrong, I apologize and we can let this go.

Pole building make great places to keep your tractor dry. They are high performance buildings in terms of being the lowest cost to erect per square foot. When one decides to repurpose one with the goal of making it energy efficient absolutely everything the made it low cost to build is now an expensive problem to be fixed. You are making a silk purse from a sow’s ear sure it can be done but you are better off starting from scratch.

When I look at the existing building I think, Is it in the ideal location? Is it the ideal size and shape? Is it the ideal floor? Is the ceiling the ideal height?

My guess is you could have the ideal building for less money than your current plan and it will be much more energy efficient than the existing one could ever be.

Walta