Perplexing Proposal for Wall Assembly

Hi everyone! Since embarking on the adventure of building a new house in Climate Zone 4A, this website and forum, along with the PGH book, has been an invaluable resource in shaping my imagination and goals for the performance, durability and efficiency of our family’s home. Throughout the process, I have found that I have had to push harder than I expected to achieve some of the basic tenets of practice that seem to be widely accepted on here.

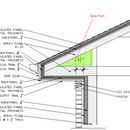

With that as a back drop, I wanted to consult the wider community. I promise that I have searched high and low for an answer to my two questions (I promise I am not being lazy), but can’t seem to find something that speaks directly to either. With my lack of experience, it’s hard for me to extrapolate conclusions for my situation from other posts and articles confidently. Below is the rendering of the proposed wall and roof assembly:

My questions/concerns are two fold:

1) If you notice, the diagram calls out Zip R9 Insulated Sheathing panels to be placed on top of standard Zip 7/16” panels. I can find zero mention of whether or not that this is an acceptable assembly from Huber or any other comment, post or article. The installation manual does mention that WSB may be used on top of it for instances like hard stucco. I will enquire from my builder why this is being proposed instead of the more common Zip + PolyIso or Zip Insulated alone. Does anyone else have a sense of whether or not this is a good idea? Has anyone ever seen an application like this?

2) My second question is a bit more controversial: The diagram also calls out open cell spray foam applied to the underside of the roof sheathing (an unvented attic). While the use of spray foam seems to have fallen out of favor on this forum for very valid and good reasons, I have decided to go along with spray foam because I am concerned about the quality of air sealing we will be able to achieve with our builder/subs in addition to being something my builder is very enthusiastic about. (Re:air barrier – we will also be using the AeroBarrier house sealing process when framing is finished and windows and doors are installed.)

If you will humor me with the use of spray foam for insulation, I am wondering whether or not to use open cell or closed cell spray foam in the attic spaces. If we assume that there will either be Zip R9 + Zip or PolyIso + Zip on the roof assembly, I am concerned that closed cell will create moisture problems in bottom Zip panels because they will effectively be sandwiched between two vapor-impermeable layers. On the other hand, it seems that the same could be said about open cell in other circumstances. I have been scouring this site and Joe Lstiburek’s writings for an answer, but because of the increasing unpopularity of spray foam I haven’t been able to find a definitive answer. I should note that I am installing a Zehnder system and an AprilAire dehumidifier – but the codes and restrictions against ventilation in attics is another confounding barrier of information on whether or not I could put an air supply from the Zehnder system and from the dehumidifier.

Thank you in advance to anyone with greater knowledge who will take the time to read and post advice. I have loved learning about building science (I have actually thought several times about how I should seriously consider a career change) but sometimes the learning curve is quite steep and confusing.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Midwest2486,

1. I can understand the extra layer of Zip on the roof, as Zip-R can't be directly attached to rafters. The only reason I can think of for the same stack-up on the walls would be if the Zip-R wasn't sufficient to provide the shear necessary. As a general comment: Two complete layers of sheathing everywhere is a lot more material and expense than the single one most walls and roofs use.

2. This article answers your question in detail: https://www.greenbuildingadvisor.com/article/sandwiching-roof-sheathing-two-impermeable-layers

Thank you for the article link Malcolm - that is very helpful indeed.

I see all that spray foam as lazy design work by someone with zero regard for your budget and I feel the same way about Zip+R.

Damp sprayed cellulose will give you almost the same R value for 1/3 the costs of the open cell foam.

R29 roof does not seem to fit you PGH goal.

Is the sloped ceiling a must have? If you need drama make the walls taller and keep the ceiling flat and covered in R60 of cheap fluffy insulation.

Walta

Thank you for the feedback walta100, and I hear you. I am working on getting clarity on why the double zip is being proposed - more than likely it's to provide a backing for the roofing material. In this case, composite synthetic shakers.

The R29 observation on the roof is greatly received and I agree; it does fall short of my goals, if not code.

If you are doing a conditioned attic anyway, I would highly recommend the "monopoly" framing approach Matt Risinger did on his own house. In that situation, the rafter tails are applied after the fact and do not interrupt the WRB continuing from wall to roof. And I would use regular sheathing (AdvanTech) followed by WRB and then polyiso. And I would do enough polyiso to where you don't even need interior insulation. Definitely not spray foam.

Did you say what type of roofing you are installing? You may not even need a full second layer of sheathing on top of the polyiso. If you are using metal roofing, for example, you can get away with furring strips instead of an entire second layer of sheathing.

Planning on needing AeroBarrier before you even begin is like admitting defeat already in my book.

This wall assembly, as you seem aware, is so bizarre. Your designer is not thinking about cost at all. A couple of thoughts:

-I personally would not use open cell spray foam. I don't think I can think of a situation that it suites the purpose better than some other method with less downsides and lower risk. I would be happy to revise this position if someone gives a good case for it.

-At a certain point, air sealing has diminishing returns, especially in 4A

- If you don't trust your builder to air seal well with zip sheathing, I would not trust them with zip sheathing at all as the air sealing is also the weather sealing

-I cant think of any reason you would ever use zip on zip, the whole point is its a single product system

-AeroBarrier makes no sense either, just a waste of money

-Zip R, while I haven't priced myself, does not seem to be worth it from a cost perspective

-Your roof r value is low

-if you build your roof as drawn with the truss and line your eave with zip, there are no tricky air sealing details to mess with. just tape your seams....

-dont use spray foam.... I am all for its use (ccSPF) by a qualified (trusted) installer if it makes sense, it just certainly doesn't here.

Consider asking your designer to hire a passive house (or just building science) consultant to help with your assemblies. Or hire them yourself, I bet they will save you more than they cost...

I would stick with closed cel spray foam here, since it has less chance of moisture issues. You won't have a "sandwich" because the closed cell spray foam creates a fully-adhered insulation layer, so no where for moisture to go in or accumulate. Open cell can act as a sort of sponge during periods of high humidity, and this can sometimes be a problem in some assemblies. Closed cell spray foam is usually the safer option.

I don't think you really need it at all though if you can seal up the sheathing materials. If you can seal the assembly with taps/sealants, then you could just blow in loose fill insulation and be done.

Bill