Opinions on my wall design?

I’m building a new workshop in Ontario. In the US, my area would be considered climate zone #5.

I’ve thought long and hard about this design, and I’m about to start building. Before I take irrevocable steps, I’d love to hear what you all have to say.

A couple of details not shown on the drawing:

– windows will be outie

– exterior EPS foam insulation is 4.5″ thick

I could really use recommendations for sealing tapes, housewrap.

Thanks,

Katou

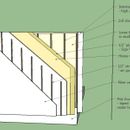

ps, here is the wall assembly from the inside out, in words if the pic isn’t working:

– interior drywall

-2×8 16″ OC stud wall, cavity filled with blown cellulose

-1/2 plywood sheathing – tape seams

-poly from foundation taped to sheathing

– house wrap – cap nail and tape seams

-4.5″ EPS – NO tape over seams

-1/2″ strapping

-fiber cement panels

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

katoutwo,

Are you sure you are in climate zone 5 ?

https://www.greenbuildingadvisor.com/article/climate-zone-map-including-canada

That wall will perform very well from both an energy use and moisture perspective. It does however go beyond a point where the high levels of insulation are justified by the ROI, and to know whether they make sense you would need to do modelling of the other parts of the enclosure (windows, doors, roof, and foundation).

I wouldn't bother cap-nailing the WRB if it is getting covered by a layer of foam. Staples are fine. As you aren't taping the exterior insulation, I would use a dimpled house-wrap to deal with any incidental moisture that gets through to it.

Another option to consider is moving the house-wrap to the outside of your foam. This would make integrating it with your window flashing much easier, and remove fears of water getting through your foam layer. You could then also set the wall in on the foundation, which would protect the bottom of the exterior insulation without having to use a wide flashing.

Great points! Thank you Malcolm.

You make a good point about cap-nailing being unnecessary. I was thinking that way myself, but I wasn't confident it would work.

I was also planning a dimpled housewrap for the same reasons you mention.

According to my research, the 4.5 EPS will function as the vapour barrier, which means that the wall will will dry to the inside. This suggests that putting the WRB on the outside of the foam.

Foam doesn't get wet, less to dry to inside.

I can't move the wall onto the foundation. The foundation is already poured to the exact size where the walls will stand. Hindsight right?

Also, if I move the WRB to the outside of the foam, I still don't need cap nails. The furring strips will secure the foam.

I'm liking this idea more and more. Fewer fasteners, less work, fewer holes in WRB!

Katou

BTW, you are correct, according to that map, I'm in Zone 5.

Oops.

Katou

In zone 5 you want at least 30% of the R value as exterior rigid to avoid needing a vapour retarder under the drywall. Assuming that dense pack is about R26, min exterior is about R10. You are well past that so not an issue. This also means you can also reduce the amount of rigid and save a bit of cost, it probably won't move your overall energy use enough to matter.

With outies, I would follow Malcom's suggestion and move the WRB over the foam. Much simpler to detail as everything is a single plane.

For tapes, you can read through here:

https://www.finehomebuilding.com/project-guides/insulation/backyard-tape-test

You can also save a bit of cost by bumping up the framing to 24OC. It would also increase your overall assembly R value a bit.

Thanks Akos, you make good points.

I got the EPS for a song, about $5/sheet from a company that was going out of business, yay for me! Cost about $2/sheet for shipping, but overall, still an amazing deal. It's the only way I would have considered this design.

I'm in Toronto, and the Building Dept rules ALL. Even though 24" OC makes sense from an insulation perspective, I went with the more common 16 oc to avoid more headaches. I'l use insulated box headers though.

The roof is a "hot roof" design, which I'm not a fan of re: shingle life. I was thinking of putting in a form (cardboard or similar) before sprayfoam is applied. This will cool the roof by providing a full-width cavity under the roof deck leading from the eaves to a continuous ridge vent

To prevent thermal bridging through the rafters, my plan is to rip 1.5" strips of XPS for the top and bottom of the rafters before the roof deck/drywall goes on.

I'm pretty much at the limit of the allowed height, so doing this pushes me over, but I can probably get away with it.

Could I get away with 1" or 1/2" XPS instead? It may seem like a lot of fuss over a small difference, but the inspectors around here can be... particular.

Katou

Katou,

I would skip the foam strips on top of the rafters for a few reasons:

- It interrupts the direct attachment of the sheathing, making the roof diaphragm weaker, and is subject to crushing (that's why Zip-R isn't rated for roof sheathing).

- It would make working up there a lot more difficult.

- Your proposed air-space short circuits the thermal break the foam gives you.

"I'm in Toronto, and the Building Dept rules ALL. Even though 24" OC makes sense from an insulation perspective, I went with the more common 16 oc to avoid more headaches."

There is nothing in the OBC that precludes using a 24" spacing for wall studs.

If you have room for vents why bother with spray foam? Just insulate with batts and call it a day. If you can't get code R value in your rafter space, you can always install a layer of contiguous rigid under the rafters. This rigid with taped seams can be your main air barrier and code required vapor barrier. You can install drywall directly over the rigid with long drywall screws or strap it out with 1x4s for the drywall.

Code officials might have issues with the lack of wall vapor barrier. Since the poly is also the air barrier, you'll have to show pictures of the taped sheathing. You might also have to point them to OBC 9.25.5.2 and the table there to show that the exterior rigid qualifies as vapor barrier for the walls and you have sufficient amount for condensation control (Toronto is less then 4999 HDD).

Value of Dimpled House-wrap for my project.

Benjamin Obdyke's Hydrogap will cost $1140

Standard Tyvek house wrap would be $113

For my project, that works out to a savings of $1000

Assuming that I put the house wrap over the foam, right next to the air gap, do you think the extra expense is worth it?

Katou

There is no reason to use a dimple house wrap next to a rainscreen. Consider using tyvek commercial.

Katou,

As freyr_design said: I'd go with Tyvek Commercial. Dimpled house-wrap only makes sense if it is going behind the foam.

Malcolm, can you elaborate on what you mean about the air gap diminishing the effectiveness of the spray foam?

If the outside of the layer of spray foam is at ambient temp, I can't see how touching/not touching the roof deck makes a difference.

I lose on the air sealing feature of the spray foam, but that is a relatively minor effect.

I hear you regarding omitting the XPS as a thermal break above the rafters, you made a good point.

I can do it on the interior side instead.

Katou

Katou,

The air-gap defeats the foam strips as a thermal break above the rafters, not the spray foam.