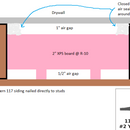

no sheathing – stud bay insulation plan

House: Alabama. Built in 1892 with Pattern 117 pine siding directly attached to the studs. No sheathing. No exterior wall insulation. Pier and beam foundation. 4 zone minisplit hvac.

Currently gutting the master bedroom which has 1 exterior (west facing) wall so I will have access to the stud bays from inside. Would the attached layout (top down view) work?

Exterior side: The siding has plenty of breathability from the siding lap gaps, so a dimple mat in the stud bay seems like overkill and would make future siding replacement more destructive. A couple of long, thin XPS strips glued to the back of the XPS board as standoffs seems like it would suffice.

Interior side: The gap behind the drywall is to help with sound dampening as we live near a busy street. Since drywall is so vapor permeable already just having a bit of air movement in the gap would be ok for inside drying?

On paper this is R-10, but the alternative is no insulation at all so I’m ok with 10 over zero.

Dave

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

timeisnotmoney,

It looks like a good plan, and is very close to what Martin recommends for walls without sheathing.

An alternative would be to tack house-wrap in the stud bays to give you a 1/2" gap, and fill the rest of the space with mineral wool batts.

If sound is an issue, I would use a different approach.

I would use a sheet of 5/8 gypsum sheathing after the gap, well sealed around the perimeter. You can then fill the remaining gap with safeNsound, this will squish down enough to fit in there. You then want 5/8 drywall on the inside, if you want better, go for two layers of 5/8 on the inside.

If you want higher R value and even better sound, same as above but build a 1 5/8 steel stud wall on the inside lined up with the existing studs but 1/2" offset. This would let you install 2x6 batts, that would be a significant bump in assembly R value plus would also be significantly better for sound.

The key to any sound reduction is air sealing, so make sure you get this right.

The air gap you show in your drawing will do almost nothing for sound.

Thank you. The 5/8 gypsum is a good idea since from what I have read, mass is a big factor in sound dampening. Would doing two layers of 5/8 create a potential mold issue between them?

I missed it in my initial post but you still need a WRB layer outside the gypsum sheathing. The simplest would be one of the fluid applied products but you can only get that in a 5 gallon pail, so not worth it for a small area. Regular house wrap will work just fine. (so gap, house wrap, 5/8 gyp sheathing, 3"safeNsound, 5/8" drywall).

The two layers of 5/8 you want on the inside. Except for the longer drywall screws, pretty simple to apply. Make sure to do a rough mud of the first layer to air seal and also seal the drywall to the framing along the perimeter.

I guess you could go for two layers of 5/8 gypsum sheathing but this is a lot of extra cut and cobble work plus you loose more cavity space. Gypsum sheathing is highly permeable, having two layers of it is not an issue.

If driving rain made it behind your siding, wouldn't you end up with wet wall studs?

Yes, but that's the case already since there is literally nothing in the stud bays since construction. I'm guessing it dries rapidly because there is no sign of rot and that side of the house gets beat to death with weather. Luckily nobody ever got "smart" and dumped cellulose in there.

I have a feeling that the improved airtightness will give you the sound transmission improvements you wish. Perhaps look up some sound specific solutions, like the special foam tape or other ways to decouple the sheetrock from the studs.

It is astounding the difference even small air leaks make. I can tell if someone shut a window improperly if there is any noise outside, it screams right through.