Performance of Incorrectly Installed Windows

I have 10ish year old Andersen Single Hung 100 series windows with Low-E and SmartSun coatings.

I realize these are entry level, but they seem to have decent infiltration rating – energy star for northern climates if the prev owners had sprung for

I had an energy audit, and the auditor mentioned something in passing about my windows being installed wrong. I don’t remember if he said anything specific, and haven’t been able to follow up with him.

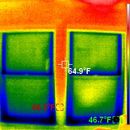

The windows face due south with direct sun just about all day in the winter. I took this thermal image one a day that was between 40 and 45 out.

Does anyone have any ideas what the inspector may have noticed from his thermal images? Is this expected performance for these windows? What can I do to improve them?

I have caulked interior and exterior trim with BigStretch. I’ll probably end up putting the heat shrink kit on and see how much that does, but not sure that will make a lot of difference on pretty new windows?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Our Andersen casement windows were installed with out spray foam. To fix I removed the interior trim and used one part.foam.to air seal them.

It's hard to say on yours w/o a blower door running. It looks.like you have a thermal bridge at the sill. What's it made out of? Can you post a non thermal.image of it?

I believe they’re vinyl.

Would it help to just blow a box fan in a window and look?

When I think of window installation issues, I don't think of efficiency so much. Basically if the gaps were spray foamed that's about all you can do. The big installation problem is making sure the exterior is flashed properly to keep water out. Number 2 I'd say is making sure the window is shimmed properly so the frame doesn't twist.

Is there a non invasive way to tell if the flashing was done correctly? I do have one window with signs of water damage.

For others with a similar question I found this link very appropriate and informative

https://www.greenbuildingadvisor.com/article/an-introduction-to-thermal-imaging

millionsofpeaches,

If you do explore behind the trim and find no foam sealant, filling the gap will be helpful in controlling air losses around the frame. Be sure to buy only low expansion foam specifically marked for window sealing. The standard Great Stuff expands a lot more initially and will continue for hours if the conditions are warm. Doing any foam in "lifts" can sometimes beat the problem of the foam expanding past the jambs and getting all over. Aside from the having to deal with potential foam pillows extending past the jambs, the ordinary expanding foam can put enough pressure on the window frame to make it bow. This bowing can make operating a single or double hung unit very hard to nearly impossible.

I thought my Pella Proline entry level windows would be more immune thanks to wood frames. I thought wrong and two of the units were rendered quite tight when opening the lower sash. So after that I made sure to take the extra trip to the store for low expansion foam.

Don't expect huge visible differences to appear on the IR. One of the visible low temp spots is caused by the metal spacer in the IGU and another is probably leaking gaskets on the bottom of the sash. Ten year window gaskets have likely suffered tears or misfolds from use. It is sometimes possible to find exact replacements for the rubber fins or fuzzy tape used in some windows. I have done the work on some of my old unmarked builder windows which helped the drapes stop moving.

If you do check the window setting by removing the trim, look very closely at the sill framing for water or damage. That will be a clue that the flashing is not 100%. Even with proper taping and setting in a wall, some windows will allow water to track down the hidden channels in the side profiles. It is anybody's guess if the WRB was placed correctly above the window. Reverse shingling of the house paper occurs much too often.

Why not use backer rod and sealant instead of spray foam for the interior window joint?

Word-all spray eventually contract and turn brittle. Yes it takes ten minutes to do this properly on each properly hung window.

"I had an energy audit, and the auditor mentioned something in passing about my windows being installed wrong. I don’t remember if he said anything specific, and haven’t been able to follow up with him."

I'd suggest finding out exactly what your auditor was talking about. All of those previous comments about a perimeter air seal and a sill pan are good possibilities.

But just to kick out yet another possibility--sometimes, windows can be installed with the insulated glazing unit (IGU) "backwards" relative to typical recommendations for a climate (location of low E coating). However, that would be a major effort to change... and it's perhaps a 10% hit on performance. If they held up a meter or a flashlight to the inside face of the glass, they might have been checking this.