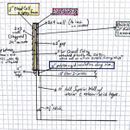

New take on double stud wall

Martin, please don’t sigh. After reading your last article, I couldn’t help thinking about another way to build a double stud wall. The only reason I’m heading down this road again is because I’m trying to cut costs while keeping the building process relatively simple. The drawing attached below essentially uses the exterior wall’s studs as the furring strips for the siding. Something I thought would be a benefit for providing a nice flat sturdy surface to attach our hardie plank siding. The air space comes from the gap between the spray foam on the OSB sheathed interior wall and the outside edges of the exterior wall’s studs. My only worry with this is whether or not there would be an issue with the exterior studs getting wet in the rain screen. I’m welcoming any opinions on this setup. Thank you.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Brian - This looks like a version of the foam covered stud wall that Martin referred to, but you're using spray foam instead of boards, and 2X4's instead of 2x6's. What I don't see is any advantages to this approach. Am I missing something? Spray foam, while environmentally a poor choice, also has no advantage to boards, and would be considerably more expensive. Are you looking to have a flatter surface with 2x3's instead of furring strips screwed through to the studs? If so, I do not think that they will be flatter, as 2x3's tend to cup and twist more than 2x4's. If you want to cut costs, forget spray foam and look for used EPS foam, with furring strips, if the EPS is available in your area.Or, consider more mineral wool in the second wall. I like the idea of a double stud wall with the air barrier in the middle of the wall. Good luck to you.

Brian,

One big issue is that your design continues the thermal bridge though the foam. That kills a lot of the R value for the same reason that spraying foam between studs isn't very efficient on the inside of the sheathing. Some people put a set of studs up on the outside of the sheathing on standoffs so that the thermal bridging in minimized. See page 41 here http://buildingscience.com/file/5806/download?token=GouEIX9Y

But you're still using closed cell spray foam - not so green.

Brian,

Sigh.

It's your house. I agree with Kevin and Bill's observations. Closed-cell spray foam is expensive and has a high global warming potential, so most green builders try to minimize the use of closed-cell spray foam. (Admittedly, a few new spray foams with more environmentally friendly blowing agents are now reaching the market, so you may want to choose one of those products.)

In your post, you wrote, "I'm trying to cut costs." If so, then it would seem obvious to me that you should follow Kevin's advice: Skip the closed-cell spray foam. Instead, buy some reclaimed (used) rigid foam instead.

If you end up going ahead with your plan, I strongly urge you to lower your brick ledge by 12 inches, to address that big thermal bridge where your foundation wall and floor joists come together.