Negative-side waterproofing in SoCal

I am asking this question since many of the high-performance home guidelines seem to only apply in the much wetter north and east. I have read most of the negative-side literature on FH, JLC and GBA but everything seems oriented to the north-east.

The context:

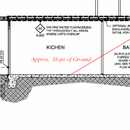

I am retrofitting a 1944 cottage in Laguna Beach, CA, which is dug into a hillside, so the bottom floor is essentially a walk-out basement. Our climate zone is 3, with low annual rainfall, and constantly mild temperatures. The one drawback is that we are oceanfront so there is high localized relative humidity (>80%). Excavation and positive-side waterproofing of the existing foundation is impossible due to almost no setbacks between adjacent buildings. The geotechnical report shows on-site soils to be cemented bedrock with very low permeability. We don’t have any bulk water intrusion but I have seen some evidence of efflorescence causing some paint to flake off, and my contractor noticed some dampness in the slab.

On the upslope wall (perpendicular to slope direction), there is an unusual cavernous plumbing chase that effectively separates that wall from the dirt, so there haven’t been many problems with that wall, but the efflorescence was on the side wall parallel to the slope direction which is in direct contact with soil (see attached elevation view). The architect has “assumed” that there is positive-side waterproofing on the plans, and specified Xypex coating for all of the negative side retaining walls, along with R-15 insulation.

The question:

Given that Xypex is still vapor-permeable, I am still worried about capillary action wetting through the walls to ruin the finishes, and the lack of slab detail. My instinct is to just put a continuous impermeable HDPE dimple-mat on all sides and have the concrete stay wet. Is this correct? Is insulating on top of the slab needed too even though I am not in a cold climate? Since relatively very little wall area of the basement is actually in contact with the ground, is this entire line of worrying actually overkill?

I am planning carpet and Armstrong Pryzm LVT as the finish floor, which aren’t that great for moist areas.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Hi Christopher.

I'm not too familiar with your very humid west-coast climate, so I hope you will get some replies from folks who are. Until then, here are some thoughts to consider or talk to your builder about.

If you are sure that damp spots on the walls and floor are not water intrusion from leaks, than you may be able to manage this with interior details.

A dimple mat is generally used inside basement walls when there is a perimeter trench for water to drain into, but it could also be used as a capillary break, to isolate stud walls and finish material from the wet concrete.

Insulating the walls and floor with rigid foam would give you some thermal and vapor control and could be caulked and taped as an air barrier to keep some of that humid ocean-side air from reaching the cool concrete.

Because wet concrete is not a problem, closed cell spray foam is sometimes used against wet foundation walls, also because it is water, vapor, and air tight.

Though concrete can stay wet, wood should not. If you take measures that don't allow the basement wall to dry, it is important that you have a capillary break between the top of the foundation wall and any framing that touches it, typically a sill plate. This is always important, but becomes even more critical once you know that the concrete has and will likely maintain high moisture levels.

Finally, I imagine you need to make sure you are properly managing indoor RH with your mechanical systems and potentially add a stand-alone dehumidifier.

Thank you!! These are excellent ideas to think about.

I'm thinking to have a polyethylene sheet capillary break directly against the concrete walls and over the slab, with the seams sealed to form a "bathtub" to prevent moisture from wicking inside. The dimple mat seems an unnecessary increase in assembly thickness since the purpose isn't to drain bulk water. Then, I will have the stud walls, permeable insulation, and permeable finishes inboard of the PE so everything else will dry to the interior.