Need for drainage gap between control membrane and exterior insulation?

Hi,

Please help me contemplate the need for a drainage gap between control layer fully adhered membranes and exterior insulation.

I am finding Building Science Corporation to be inconsistent on this issue.

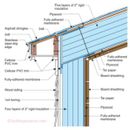

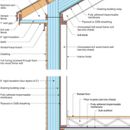

Looking for example at Figure 1 in BSI-056

(https://buildingscience.com/documents/insights/bsi-056-leiningen-versus-the-ants-redux)

and Figure 1 in BSI-031

(https://buildingscience.com/documents/insights/bsi-031-building-in-extreme-cold)

Another interesting difference between these two is “how the “under” roof is drained over the top of the wall”, in the words of BSI-056.

I would appreciate any feedback!

Thanks

Ben

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

* I'm in zone 7 but the question is general.

also correction for the second link:

https://buildingscience.com/documents/insights/bsi-031-building-in-extreme-cold

how do you edit questions?

Ben,

1. Historically, the developer of Building Science Corporation details (Joseph Lstiburek) has been inconsistent.

2. For a recent discussion by Lstiburek about the issue you raise -- whether or not you need a drainage gap between a WRB and exterior rigid foam -- see this article: Mind the Gap, Eh!

3. As far as I know, GBA readers can't edit questions. When you need to edit a question, you have to ask for help from an editor. I have corrected your second link.

Thanks!

I should have clarified, I'm not referring to a rain screen gap behind the cladding (like BSI-038 discusses) but a drainage plane between the control layers and exterior insulation, marked in the figure as "draining building wrap". does it depend on the type on membrane used? is there any reason not to include a drainage gap like that?

Am I nitpicking here?

HI Ben, I have been looking for answers to your question also, did you get any further with it?

Ben,

I understood your question. Read the article I linked to. In that article, Lstiburek wrote, "This installation of foam sheathing over OSB sheathing leads to some interesting questions - some with very easy answers, some with not so easy answers. ...

"What if I use a vapor closed cavity insulation? Well, we now have a problem. Ah-hah – a problem! Yes, closed cell high-density foam cavity insulation applied to the inside of OSB sheathings that are in turn covered on the exterior with impermeable foam sheathings is risky. Unless you provide a small gap between the exterior face of the OSB and the back surface of the foam sheathing to provide for some hygric redistribution. Or if you are “perfect” with your rainwater control such as when you use a fully adhered membrane – think roof membrane standing up applied to a wall. Otherwise, go with a gap. What works? Grooved foam, “bumpy” OSB, “crinkled” building wrap, 1/8-inch polypropylene mesh, dimpled polypropylene sheets. Lots of stuff (Photograph 9 and Photograph 10). But won’t the tiny gap cause a loss of thermal performance of the foam sheathing? Yes. How much? About 5 percent of the thermal performance of the foam sheathing (not the entire wall assembly) with the 1/8-inch gap, less with a smaller gap. With “crinkly” stuff you loose next to nothing.7 Is it worth it? Yes, in my opinion, the loss in thermal performance is trivial compared to the reduced risk and improved durability. The 5 percent thermal loss is also easily offset by the improved thermal performance of the closed cell high-density foam cavity insulation. Even if you think you are perfect with a water control membrane, go with a gap for at least the relief of hydrostatic pressure. ..."

There's more, so it's worth reading the whole article.