Multi-zone Mitsubishi system is not performing with all zones running

Earlier in the year I had a four zone Mitsubishi system installed. Since the install wrapped up I’ve been chasing performance issues which my contractor has not been able to get to the bottom of at all.

The system consists of:

-

MXZ-8C48NAHZ

-

PAC-MK51BC

-

2x MSZ-FH09NA (Kitchen and Sunroom)

-

MFZ-KJ09NA (Office)

-

SVZ-KP24NA (Bedrooms and Bathrooms)

The ductless units have generally performed well from the start, but the SVZ air handler has never been able to hold a set point or adequately remove humidity. Oftentimes the supply and return temperatures for the air handler are within a couple degrees of each other or exactly the same.

Yesterday I discovered that the problems with the air handler go away completely if it is the only zone running. Currently with just the air handler running I’m seeing temperatures of 53°F at the supply vents and 71°F at the return vents.

Has anyone out there experienced a similar issue? Previously I was thinking that there was maybe a kinked lineset going to the air handler or a faulty LEV in the branch box, but now I’m starting to think it’s simply undercharged. FWIW, the weight of the refrigerant the contractor provided matches up nearly exactly with what Mitshibishi’s Diamond System Builder gave me when I plugged everything in with ballparked lineset lengths.

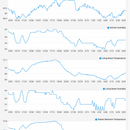

I’ve attached a screenshot of some data logs for the last 24 hours. Notice that around 6AM today when I turned on the floor unit in the office that the supply temperature for the air handler began dropping off almost immediately.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

If you set all units to 60F at the same time, is it able to provide cooling to all units full blast? That would help narrow down if it is undercharged.

It does not. Setting everything to minimum (61 on the wall units, 67 on the air handler) results in the air handler basically not doing anything at all and the wall units cooling adequately (but maybe less than they should be).

I'll point out that the air handler is on the 'last' port on the branch box (port E) because it has a larger gas pipe connection.

Sounds like you are low- problem is have you always been low or is there a leak somewhere. Did your installer not hook up his gauges and try that?

These systems are pretty particular on refrigerant levels - you need to do nitrogen pressure tests and be able to hold a vacuum for 20-30 minutes, a lot of contractors skimp on this.

I'd pay a Diamond contractor to sort it out (I had to as well), around me they were worth the money.

The installer actually is a Diamond Elite contractor. I'm now convinced that it means absolutely nothing other than the fact that they are able to move a lot of Mitsubishi product. If you haven't seen it, you should take a look at one of my previous posts on the disaster that the original install was here: https://www.greenbuildingadvisor.com/question/a-cautionary-tale-on-hvac-contractors

I don't suspect a leak in this case because system performance has been consistently bad with everything running from day one. Even after they pumped down the system, relocated the branch box, outdoor unit and linesets the performance didn't change at all.

I remember that one- never fun. Well I would assume they would be able to properly charge the system in that case and it's not some hack off the street.

There are power limit considerations depending on the combination of indoor/outdoor/branch boxes. Have a look at this tech note and make sure you not running afoul of any limits. Some applications require an extra power supply.

http://meus1.mylinkdrive.com/sfiles/Application_Note_1029-Ducted_Air_Handlers_and_MXZ_configurations_v1_4.pdf

> MXZ-8C48NA, 4C36NAHZ, 5C42NAHZ, 8C48NAHZ:

> • No more than two MVZ/SVZ indoor units may be connected.

> • When two MVZ/SVZ indoor units are connected, no other indoor unit may be connected.

> • When at least one MVZ/SVZ indoor unit is connected, the total capacity must not exceed 130%.

Definitely good on this. Total connected capacity is 51,000 BTU (9k * 3 + 24k), so this configuration is at around 106% of the 48k the MXZ-8C48NAHZ is rated for.

Measuring pressure in the various states makes sense to me. Measuring compressor amps would also be a clue - the compressor not running at high power when the SVZ isn't working well could be a control problem.

It's really hard to tell. I was completely on board with this being a control problem until I found that the air handler runs exceptionally well on it's own.

With the air handler and a single wall unit running the air handler somewhat works, but the supply temps on the air handler indicate that it's running at a greatly diminished capacity (currently around 65ºF) compared to what it can do running solo.

I can measure whole house power consumption with my Sense -- I have never seen the system draw anywhere near full power under normal operating conditions. Sometimes if I cycle everything off and then back on some time later I will see the power consumption spike to full load for a brief period of time (~15-30 minutes).

You wont see full power during cooling unless it's something like 120f outside, and your indoor return air temps and wetbulb are at the top of the scale.

> I will see the power consumption spike to full load for a brief period

Do things work better during this period?

Sounds like a control problem - the compressor is capable of high output (suggesting charge is OK), but most of the time, something is telling it to cut back. Low compressor output (~50%?) is consistent with the air handler working OK alone.

Thermostat issue? Some safety limit sensor?

I have NOT noticed an improvement in performance from a full reset like I described. In general it's very inconsistent -- sometimes I'll see power consumption spike over 3000W+, other times it will pick right back up at around ~1500W (or less).

Looking at the service manuals, it seems like things need to be pretty far out of whack to trigger an actual error code. For example -- for code 1501 "Refrigerant shortage trouble" discharge superheat would have to be >144ºF, which seems insanely high based on the research I've done, but I am definitely not an HVAC tech.

The contractor currently suspects a thermostat issue, but I don't see how that would be possible with this type of thermostat (MHK1) when there are no signs of communication issues.

Your system is very similar to my 5-zone system I had installed in March.

Was the total system charge recorded? My system needed 19 pounds total. Installers usually know how to figure the extra refrigerant requirement for the line sets, but I’ve been told it’s quite common for installers to forget to account for the additional refrigerant requirement for “total capacity”, which in your case is 88 ounces (see page 7 of the attached). Your system definitely would not operate optimally if its 88 ounces short.

Also, if your SVZ is in a hot attic and with insufficiently sealed/insulated ductwork you could be losing a ton (literally) of cooling, particularly in the afternoon when attics, such mine, can hit +120f.

My SVZ ductwork is all covered in the (often performance misrepresented) foil bubble wrap, VERY inadequate. I noticed a big performance drop in register temperature output when the attic is hot.

https://meus.mylinkdrive.com/files/MXZ-8C48NA_MXZ-4C36-5C42-8C48NAHZ_Install_RG79D595H05_03-15.pdf

https://youtu.be/RiBjwQbpFe8

Total system charge was recorded as 21.2lb. When I plugged in my system to Mitsubishi Diamond System Builder with estimated lineset lengths, I received 20.8lb as the correct total. It's likely my estimates for lineset length as causing the discrepancy there.

My SVZ air hander is in what is currently unconditioned attic space, but I'm not certain that's not the root cause of the issue. No matter how hot the attic is, the air handler performs well when run on it's own.

All of my ductwork is wrapped in R8 fiberglass wrap or is R8 flex duct and everything is correctly sealed. Supply temperatures are good even on the hottest days when running the air handler by itself.

Is this an issue only in cooling or both cooling and heating?

I heave a feeling that something is not configured or wired properly. I would check the install manual and compare to the actual setup to make sure the switches are all set correctly and the control wires are connected to the correct ports.

Multi splits can operate in strange ways when low on refrigerant. I had one that was a bit low that would run fine with two heads one, but would provide no heat or cooling with a single head. Since it is a newish install, I doubt it would be a refrigerant issue unless the installers really messed something up.

I have not had an opportunity to test heating performance at all yet.

As best I can tell all the wiring and addressing is correct -- every zone operates correctly when operated independently with consistent delta temps of around 27F for the wall/floor units and around 18F for the air handler (as measured at supply/return grilles, not the air handler itself).

I wouldn't put it past the installers really messing something up with the refrigerant. The outdoor unit, branch box and several linesets were all relocated at one point during the install (after the system had already been charged).

Hi,

Did you ever find a solution?

This is also happening with my 5-zone Mitsubishi multi split system.

On hot days I notice that my 18,000 Btu SVZ air handler would perform perfectly when the other 4 other head units are off but if I turn on another head unit the performance immediately drops off to the point the SVZ is not able to keep up on hot summer days.

For example this afternoon it was 85 F outside and sunny. Running by itself the SVZ air handler cools nicely with duct outlet registers reading 49F. But when I turn on the kitchen MLZ cassette the temperature of the SVZ air handler ducts registers quickly rises to 60F+ and no longer keeps up with the room heat load.

If I turn the kitchen MLZ cassette back off then the SVZ starts performing perfectly again (back to 49F). I can reproduce this scenario using any of the other indoor head units.

Turning on additional head units (3rd 4th, 5th) doesn’t further degrade the SVZ air handler performance AND all other head units perform perfectly regardless of how many zones are in use. Only the SVZ air handler doesn’t perform well with others.

Total connected capacity is 51,000 BTU (9k, 9K, 9k, 6K, 18k), so this configuration is well in range of the 48k the MXZ-8C48NAHZ is rated for.

Mark

After many, many hours of tech assistance with Mitsubishi the following two changes has fixed the issue:

1-Air Handler static pressure setting was changed from 0.5” to 0.8” (using mode 08 on the programmable thermostat)

2-Outdoor unit dip switch#SW6-8 was changed from off to on, which according to the service manual changes the “Target ETm (C)” from “9” to “6”.

Does anyone know what “Target ETm “ means? or have a theory why these settings would suddenly solve the problem.

I’m very curious?

Evaporator temperature, which controls latent (water) removal. I'm going to guess absolute values (vs delta), so 6C is colder, which takes more compressor output to achieve. It may have been backing off the compressor once the old target temp (9C) was reached. A static pressure/airflow issue would cause 9C to be achieved at too low compressor output.

Thanks.

Just wanted to say thank you for this post. I suffered with the same issue last summer after having the system installed and after making the suggested changes, the air handler was able to keep up with today's 90 degree day. Really appreciated.

I wanted to follow up on this thread with an outcome in the hope that it helps someone else in the future.

Back in July the installer finally came back out for yet another visit. Fortunately this was actually a hot day and we were immediately able to reproduce the issue with the air handler supply temperatures with all zones running.

They ended up spending a couple hours on the phone with Mitsubishi, concluded that the system definitely was undercharged and ultimately ended up adding an additional 2lb (!!) of refrigerant to the system over the course of about an hour. They did also change the air handler static pressure and Target ETm, though I ended up setting the static pressure back to the more appropriate 0.5" default.

The system has been performing basically flawlessly since then. Energy consumption has been good for a (somewhat) leaky 70s house. I used ~300kWh more energy in August 2019 versus August 2018 while air conditioning the entire house rather than just a couple rooms. In September 2019 I used nearly 600kWh LESS than the previous year.

We had some cold weather earlier in November (down to about 18ºF overnight) and we saw no problems at all with performance, though I do admit certain rooms in the house were a bit less comfortable than using the (now disabled) boiler and baseboard convectors.

It’s comforting that your issue seems to have been resolved with the same fix as mine.

I also changed the static pressure back to 0.5”. Fan noise was way loud at 0.8”

Everything seems to be working so I really think (err hope) the Target ETm (C)” from “9” to “6” is the fix for the AC performance issue.

The real culprit in my case was definitely being undercharged -- I had previously tried changing the ETm to the minimum and while it did improve things it did not actually solve the issue.

In general my understanding is that these system will tolerate being slightly overcharged, but will not tolerate being undercharged at all. This was compounded on my system by the fact that the air handler also has the longest lineset. Out of curiosity, does your air handler also have the longest lineset?

Yes. Also longest.

My system was not undercharged and in my case the ETm change was the fix.

Now that it is performing well, just work on balancing. if one thermostat is running rooms that are warm and rooms that are too cool, weaken the flow to the warmer rooms so the cooler rooms have time to warm up

I have a four ton Mitsubishi outdoor unit with two MVZ-A24AA4 (2 ton) air handlers through the manifold box. I experienced similar issues (and still do).

I have to concur about the installers. First, the documentation is overly complex and hard to decipher. Second, the service techs don’t have sufficient training.

Anyhow, my unit behaves as if there is insufficient refrigerant but the tech says its fine. We tried a few things mostly trying to load up the compressor by turning down the thermostats to 67F the lowest they are configured to go. Then he checked the suction pressure and it seemed fine.

Let me digress a bit with more description of the installation. The house is a 1900 two story with basement (unfinished). It’s approximately 38 feet square. There is a zone upstairs and a zone downstairs each with their own air handler which feeds four rooms on each floor. Downstairs is kitchen/DR/Parlor/Parlor but only a powder room. The units are controlled with hardwired PAR32MAA controllers.

My compressor died under warranty and it was replaced last year. I thought there may be some debris in the lines causing erratic behavior. Some times it would be okay and other times it would not.

It was fairly hot outside so we had a good chance to tax the capability of the installation. The tech could not figure out any problem when he reviewed the connections. He ran the self test and saw the coil temp was good (43F) on the upstairs trouble unit. And the air was in 50s at the register. We both agreed it sounded as if the valves were not always opening. But there were no error codes to confirm this. I guess that is all they have to go on.

He showed me how to run the self test so I might look for error codes and he was done. We had a nice conversation and he only charged me for an hour instead of the full time he was there.

I had been pretty much done with this outfit but did not want to explore a new devil so I put up with seeing not much alternative.

So after he left the unit starting misbehaving again and I started looking at the controller manual again. I did not find much joy there.

Thanks for that comment above about running two air handlers max on the the outdoor unit. I did not know that. My indoor capacity matches outdoor so I think we are safe.

One thing that is problematic is that there are two controllers that seem to be independent. Each one controls and air handler but you cannot run one on heat and the other on cool for the obvious reason. Nevertheless, the controller allows you to do it. I find that I have to power off at the controller and then go to the other unit and set the mode and then return to the powered off unit to set the mode. I am saying this because I found a way to get my unit to perform properly but the mode conflict screws it up.

When I put both units in auto they can draw down the temperature as expected. However, if the set point moves above the temp a unit might shift into “auto heat” mode ruining my setup. It’s hot here so I don’t want heat at this time.

Until you mentioned that your issue was resolved adding refrigerant I was convinced there was a configuration/wiring issue here. Now I need to start over with another session to get the tech out here with his gauges so we can get this cranked up and then measure the suction/discharge pressure.

The out door unit is on grade level and downstairs air handler is about the level too. The upstairs unit is in the crawl space above the second floor so that is about 22 feet above grade. This is within spec so I don’t see a head pressure issue here.

Anyhow thanks for the useful dialog. I certainly learned some things.

Paul

I would question why your compressor failed in the first place. These things are reliable, a unit failing early on is very questionable.

If the folks doing the original install did a bad job of purging the joints while brazing and there is junk in your lines, chances are you'll have to replace more than the outdoor unit.

I would bet that the installers did not purge or use a nitrogen charge when soldering. Perhaps they leaked lubrication from a poorly sealed joint until the unit died.

Now that I know how to start the test mode I can kick both air handlers on simultaneously and check performance. The device has internal temperature sensors that will indicate coil temperature during the test. I can use this with the chart to check refrigerant. I have to dig out my gauges and see what suction pressure looks like. I don't have a recovery unit so I have to rely on these inferences which should be fairly reliable.

As you point out my biggest fear is that my line set and valving is getting hung up with debris. This would be catastrophic and require disassembly and replacement of control parts. So keeping my fingers crossed.